What Is a Plate Fin Heat Exchanger? Design, Working Principle, and Applications

Understanding how these exchangers work, their design principles, and where they excel can help engineers and facility managers make informed decisions about thermal management solutions.

In the realm of thermal operation and artificial heat transfer, the plate fin heat exchanger stands out as one of the most effective and compact results available. This sophisticated piece of engineering has revolutionized diligence ranging from aerospace and cryogenics to petrochemical processing and automotive manufacturing. With its exceptional heat transfer capabilities packed into a remarkably small footmark, the plate fin heat exchanger has come necessary in operations where space, weight, and thermal effectiveness are critical considerations. Understanding how these exchangers work, their design principles, and where they exceed can help masterminds and installation directors make informed opinions about thermal operation results.

What Is a Plate Fin Heat Exchanger?

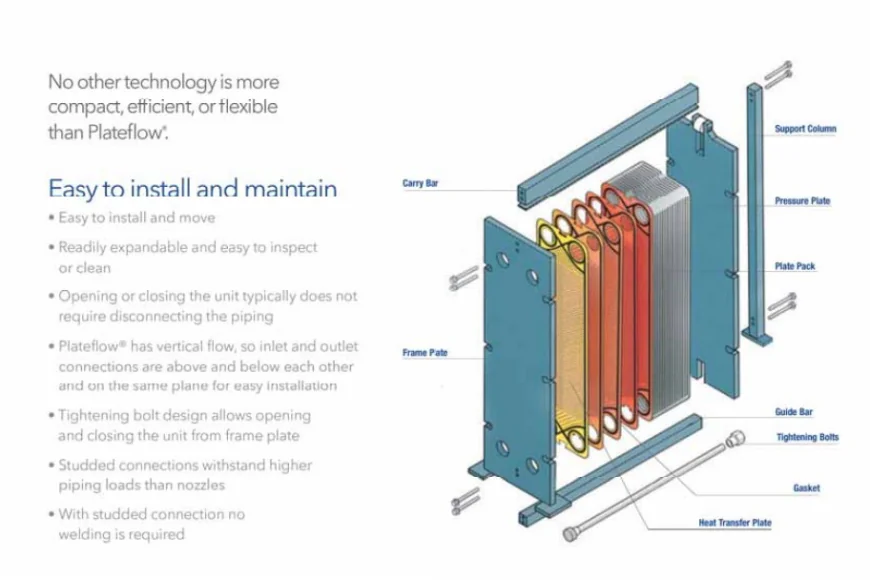

A plate fin heat exchanger is a type of compact heat exchanger that uses plates and finned chambers to transfer heat between two or further fluids. The design consists of interspersing layers of flat plates (called parting wastes) and corrugated fins, which are piled and brazed together to form a solid block. The fins produce multitudinous small parallel inflow passages, dramatically adding the face area available for heat transfer while maintaining a compact overall size.

Unlike traditional shell and tube heat exchangers, plate fin designs can achieve face area consistence exceeding 1,000 square measures per boxy cadence, making them up to five times further compact than conventional designs with original thermal performance. This remarkable space effectiveness, combined with their capability to handle multiple fluid aqueducts contemporaneously, has made plate fin heat exchangers the technology of choice for demanding operations.

Design Components and Construction

Core Elements

1. Parting wastes (Plates)

The flat essence plates separate different fluid aqueducts and give structural integrity to the exchanger. These wastes are generally made from aluminum, pristine sword, or specialized blends depending on the operation conditions and fluid comity.

2. Corrugated Fins

The fins are thin essence wastes formed into colorful corrugated patterns similar as plain, saw-toothed, perforated, or crimpy configurations. These fins serve multiple purposes:

- Creating inflow channels for fluids

- Maximizing heat transfer face area

- Providing structural support to the plates

- Enhancing turbulence for advanced heat transfer portions

3. Side Bars and heads

These factors seal the edges of the piled assembly and direct fluid inflow into and out of the applicable passages. They insure that different fluid aqueducts remain separated while flowing through the exchanger.

4. Brazed Construction

The entire assembly is joined through vacuum brazing, creating a endless, leak-tight bond between all factors. This process results in a robust, pressure-resistant unit able of opposing demanding operating conditions.

Fin Configurations

Different fin shapes offer varying performance characteristics:

- Plain Fins - Simple, provident, suitable for clean feasts

- Serrated Fins - intruded shells that enhance turbulence and heat transfer

- Perforated Fins - Include holes to ameliorate fluid mixing and reduce pressure drop

- Crimpy Fins - give a balance between heat transfer improvement and pressure drop

- Offset Strip Fins - Offer excellent heat transfer performance for gas-to-gas operations

Working Principle

The operating principle of plate fin heat exchangers relies on conduction through the essence shells and convection with the flowing fluids. Then is how the process works:

Step 1: Fluid Entry

Multiple fluid aqueducts enter the exchanger through designated bay anchorages. Each fluid is directed to its specific set of inflow passages created by the interspersing plate and fin arrangement.

Step 2: Flow Distribution

The fluids flow through the narrow channels formed between the fins and plates. The corrugated fin structure promotes turbulent inflow, which significantly enhances the convective heat transfer measure.

Step 3: Heat Transfer

As hot and cold fluids flow through conterminous passages (separated only by thin essence walls), heat transfers from the hotter fluid through the essence face to the cooler fluid. The large face area handed by the fins facilitates effective thermal exchange.

Step 4: Counterflow or Crossflow Arrangement

Fluids can be arranged in counterflow (contrary directions), crossflow (vertical directions), or mongrel configurations to optimize thermal effectiveness grounded on the specific operation conditions.

Step 5: Fluid Exit

After swapping heat, the fluids exit through their separate outlet anchorages, having either gained or lost thermal energy as intended by the process design.

The thin essence walls, large face areas, and enhanced turbulence combine to produce exceptionally high heat transfer portions, making plate fin heat exchangers remarkably effective compared to conventional designs.

Key Advantages

Compact Size and Low Weight

The high face area viscosity allows for significantly lower and lighter units compared to shell and tube designs — a critical advantage in aerospace, automotive, and mobile operations.

High Thermal effectiveness

The large heat transfer face area and enhanced convection result in thermal effectiveness that can exceed 95 in counterflow arrangements.

Multi-Stream Capability

A single unit can accommodate three or further fluid aqueducts contemporaneously, simplifying system design and reducing the number of individual exchangers needed.

Cost-Effective Manufacturing

Mass product ways and standardized designs make plate fin heat exchangers economically seductive, especially in high-volume operations.

Reduced Fluid force

The compact internal volume minimizes the quantum of precious or dangerous fluids held within the system at any given time.

Industrial Applications

Aerospace Industry

Plate fin heat exchangers are considerably used in:

- Aircraft environmental control systems

- Energy thermal operation

- Turbine machine cooling

- Hydraulic oil painting cooling

The aerospace assiduity particularly values the weight savings and trustability of these exchangers, where every kilogram matters for energy effectiveness and cargo capacity.

Cryogenic and Gas Processing

These exchangers exceed in cryogenic operations similar as:

- Deiced natural gas (LNG) product

- Air separation shops

- Hydrogen liquefaction

- Artificial gas manufacturing

Their capability to handle extremely low temperatures and multiple process aqueducts makes them ideal for complex cryogenic cycles.

Petrochemical Industry

operations include:

- Natural gas processing

- Hydrocarbon separation

- Refinery process cooling

- Gas dehumidification units

Automotive Sector

Modern vehicles use plate fin heat exchangers for:

- Charge air cooling (intercoolers)

- oil painting cooling

- Transmission cooling

- Battery thermal operation in electric vehicles

HVAC and Refrigeration

These systems profit from:

- Compact air exertion units

- Heat pump operations

- marketable refrigeration

- Data center cooling

Power Generation

Plate fin technology supports:

- Gas turbine cooling systems

- Combined cycle shops

- Waste heat recovery

- Energy cell thermal operation

Considerations for Selection

When specifying a plate fin heat exchanger, masterminds should estimate:

- Operating Pressures and Temperatures - insure material selection and design can repel process conditions.

- Fluid comity - Consider erosion eventuality and material comity with process fluids.

- Fouling Implicit - Clean fluids are essential; fouling can significantly degrade performance, and these units are delicate to clean mechanically.

- Pressure Drop Conditions - The narrow passages can produce advanced pressure drops compared to other designs.

- Thermal Duty and Effectiveness - Match the exchanger's capabilities to reprocess conditions.

Partner with Thermal Engineering Experts

picking and enforcing the right thermal operation result requires moxie and quality manufacturing. Kinetic Engineering offers comprehensive results for artificial heat transfer needs, including technical plate heat exchanger designs acclimatized to different operations. With their commitment to engineering excellence and proven track record in delivering dependable thermal operation outfit, Kinetic Engineering helps diligence optimize their processes while icing long-term performance and effectiveness. Their platoon of experts can guide you through the selection process, icing you get the most applicable result for your specific functional conditions.

Conclusion

Plate fin heat exchangers represent a zenith of compact, effective thermal operation technology. Their unique design combining plates and corrugated fins creates an exceptionally effective heat transfer medium in a remarkably small package. From enabling space disquisition to making ground transportation more effective, these exchangers have come essential factors across multitudinous diligence. As technology advances and demands for energy effectiveness consolidate, plate fin heat exchangers will continue to play a pivotal part in thermal operation results worldwide. Understanding their design, working principles, and operation strengths empowers masterminds to work this technology effectively, optimizing performance while minimizing space, weight, and energy consumption in their systems.

rillanthony

rillanthony