How Sound Absorption Works in a Full Anechoic Chamber

A Full Anechoic Chamber is one of the most advanced innovations in modern acoustics.

The Science Behind Total Silence: Inside a Full Anechoic Chamber

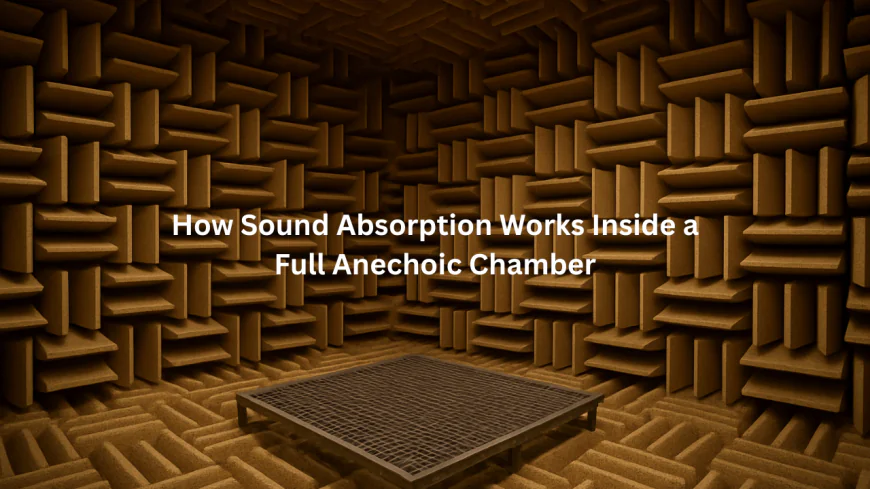

A Full Anechoic Chamber is one of the most advanced innovations in modern acoustics. It’s a specialized room built to eliminate all sound reflections and block external noise — creating an environment so quiet that even the faintest sounds can be detected. Used for research, product testing, and precision calibration, these chambers are essential for industries that rely on accurate sound measurement.

Whether it’s testing microphones, speakers, or mechanical components, a Full Anechoic Chamber provides a completely controlled sound field — something impossible to achieve in normal rooms. Companies like Ecotone Systems design high-performance acoustic chambers that help engineers and researchers measure sound behavior with unmatched precision.

What Makes a Full Anechoic Chamber Unique

A Full Anechoic Chamber absorbs sound from every surface — the floor, walls, and ceiling — ensuring no reflections return to the source. This creates a “free-field” condition, similar to being outdoors in an infinite open space.

Industries use these chambers to:

-

Measure sound pressure levels accurately

-

Analyze product noise emissions

-

Calibrate microphones and sensors

-

Study sound directivity and speaker response

-

Conduct psychoacoustic experiments

-

Design advanced noise control materials

Unlike a Semi Anechoic Chamber, which has a reflective floor for heavy equipment testing, a Full Anechoic Chamber delivers complete absorption — ideal for high-precision acoustic experiments.

Why Sound Control Is Important

In ordinary rooms, sound bounces off hard surfaces, creating reflections, echoes, and reverberation. These unwanted effects distort acoustic measurements.

To achieve accurate readings, sound must be controlled through three main principles:

-

Reflection Control – Hard surfaces reflect sound waves, causing echo and distortion.

-

Diffusion Management – Scattering surfaces spread sound unevenly, leading to unclear results.

-

Absorption Enhancement – Specialized materials absorb sound energy and convert it into heat through internal friction.

A Full Anechoic Chamber combines all these principles, resulting in a pure, reflection-free sound environment.

How Sound Absorption Actually Works

Sound absorption in a Full Anechoic Chamber happens through a blend of design, materials, and geometry. Here’s how each component plays its role:

1. Wedge-Shaped Acoustic Absorbers

The most recognizable feature inside the chamber is the foam or fiber wedges installed on every surface. These are typically made of:

-

Melamine foam

-

Glass wool

-

Polyurethane foam

-

Mineral fiber

-

Advanced composite materials

When sound waves enter a wedge, they get trapped, bounce multiple times inside, and gradually lose energy. This repeated absorption converts the sound energy into heat, leaving the environment almost completely silent.

A well-designed wedge system can achieve a Noise Reduction Coefficient (NRC) above 0.99 — meaning it absorbs 99% of the sound energy.

2. Simulation of a Free-Field Environment

A Full Anechoic Chamber recreates the conditions of an infinite open space. It achieves this by:

-

Preventing reflections on all sides

-

Maintaining low background noise

-

Controlling temperature and humidity

-

Using absorption material across every surface

This allows for precise testing of:

-

Speaker directivity

-

Source strength and frequency response

-

Sound distortion and harmonics

3. Vibration Isolation and Structural Design

External vibrations can easily interfere with sensitive acoustic measurements. To prevent this, the chamber is built using:

-

Floating floors

-

Spring isolation systems

-

Air-mount isolators

-

Multi-layered wall structures

-

Vibration-damping pads

These elements ensure that external noise from vehicles, footsteps, or nearby machinery doesn’t enter the chamber.

4. Precision-Sealed Acoustic Doors

The door design is crucial to maintaining full isolation. It features magnetic or mechanical seals and perfectly aligned surfaces to prevent even the smallest sound leaks. A minor gap could compromise the entire chamber’s acoustic integrity.

5. Control of Reverberation Time

The chamber aims for an RT60 (reverberation time) of nearly zero — typically below 0.1 seconds — and background noise as low as 10–15 dB(A). This makes it one of the quietest environments on Earth.

Why a Full Anechoic Chamber Offers Superior Accuracy

Because it eliminates all reflections, a Full Anechoic Chamber provides unmatched accuracy for:

-

Audio equipment testing

-

Loudspeaker calibration

-

Fan and motor noise analysis

-

Product certification and quality assurance

-

Research and development in acoustics

For engineers and scientists, this level of precision ensures data reliability and compliance with international testing standards.

Inside the Engineering Design

A high-quality Full Anechoic Chamber integrates science with structure. The key components include:

-

Acoustic Wedges: Designed for maximum absorption efficiency.

-

Metal or Concrete Shell: Blocks external noise infiltration.

-

Floating Floor System: Prevents vibration transmission.

-

Wire Mesh Walkway: Provides a stable, non-reflective testing surface.

-

Acoustic Door Seals: Maintain sound isolation.

-

HVAC Noise Control: Ensures airflow without disturbing silence.

Common Applications

Full Anechoic Chambers are essential in:

-

Automotive: Testing engine and EV component noise.

-

Aerospace: Measuring aircraft sensors and communication systems.

-

Electronics: Testing fans, compressors, and audio devices.

-

Research Labs: Conducting acoustic experiments.

-

Audio Industry: Designing and testing microphones, speakers, and headphones.

Full vs. Semi Anechoic Chambers: The Key Difference

A Full Anechoic Chamber absorbs sound from all six surfaces and is ideal for precision sound testing.

A Semi Anechoic Chamber, however, has a solid reflective floor, used mainly for vehicle and heavy equipment testing.

In short:

-

Full = Total sound absorption

-

Semi = Partial absorption with a reflective base

Why Professional Design Matters

An improperly designed chamber can result in inaccurate data, faulty product validation, or non-compliance with standards. That’s why industries trust experts like Ecotone Systems, who specialize in building fully customized, high-accuracy acoustic chambers for industrial and research applications.

Conclusion

A Full Anechoic Chamber represents the pinnacle of acoustic engineering — a space so silent that even the quietest sound can be heard. Through its innovative design, wedge absorbers, vibration isolation, and precision construction, it delivers flawless acoustic performance.

As industries evolve toward quieter, more efficient, and reliable products, the demand for these chambers continues to grow. Understanding how sound absorption works inside them helps professionals appreciate their vital role in advancing noise control and acoustic innovation.