Welding Gun: A Comprehensive Guide for Industrial Manufacturers

Heron Welder provides a full range of manual and automated welding guns, backed by technical expertise and global support.

In modern manufacturing, precision, speed, and reliability are crucial. One of the most essential tools in metal-joining processes is the welding gun. From automotive assembly to industrial fabrication, welding guns form the backbone of resistance welding and automated production lines. In this guide, we explore the principles, types, applications, and best practices for welding guns, helping engineers, OEMs, and automation integrators make informed decisions for their factories.

What is a Welding Gun?

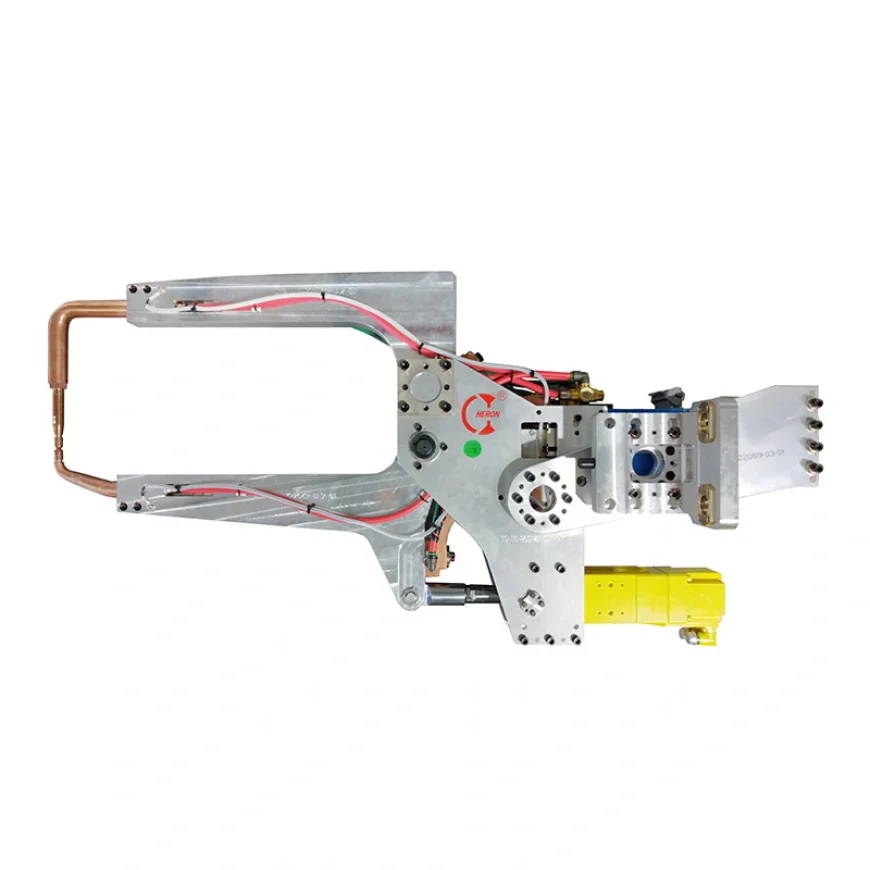

A welding gun is a device designed to deliver controlled electrical current and pressure to metal components, facilitating their joining through resistance welding. These tools are widely used in spot welding, projection welding, seam welding, and capacitor discharge welding.

At its core, a welding gun consists of:

-

Electrodes: Conductive tips that clamp the workpieces and transmit electrical current.

-

Gun Body/Frame: Houses the electrodes and allows manual or robotic handling.

-

Cooling System: Often water-cooled to maintain electrode temperature during high-cycle production.

-

Control Interface: Integrates with welding machines for precise current, pressure, and timing adjustments.

The right welding gun ensures repeatable weld quality, reduces cycle time, and extends electrode life, making it a critical investment for any manufacturing facility.

Types of Welding Guns

Choosing the appropriate welding gun depends on the specific application, material thickness, and production requirements. Heron Welder offers a range of industrial welding guns tailored to different processes:

1. Spot Welding Guns

Spot welding guns are widely used in automotive, appliance, and sheet metal fabrication. They deliver high-current pulses between electrodes to create localized welds. Key features include:

-

Pneumatic or hydraulic actuation

-

Water-cooled electrodes for high-duty cycles

-

Manual or robotic integration

2. Seam Welding Guns

Seam welding guns use rotating electrodes to produce continuous welds along a metal seam. Ideal for fuel tanks, HVAC ducts, and industrial containers, they provide leak-proof, high-speed welding.

3. Projection Welding Guns

Projection welding guns are optimized for components with embossed projections or studs, concentrating the current at specific points for strong, repeatable welds. Common in fastener attachment and automotive assemblies.

4. Capacitor Discharge Welding Guns

These guns are perfect for thin materials and delicate electronics, offering short, high-energy pulses to minimize heat distortion.

5. Specialized Guns: MFDC, FSPR, and Automated Systems

-

MFDC Welding Guns: Controlled direct current for medium-frequency resistance welding, reducing energy consumption and improving weld consistency.

-

Self-Pierce Riveting (FSPR) Guns: Combines riveting with welding for joining dissimilar metals in automotive lightweighting.

-

Automated Welding Guns: Designed for integration into robotic lines and automated production cells, enhancing throughput and reducing operator fatigue.

How Welding Guns Work: The Principle

The welding gun operates on the principle of resistance heating. When electrical current passes through the contact points of metal sheets, the resistance generates localized heat, causing the metal to melt and fuse. Simultaneously, the electrodes apply mechanical pressure to ensure a strong bond.

Critical parameters that influence weld quality include:

-

Current intensity

-

Electrode force/pressure

-

Weld time and pulse duration

-

Material type and thickness

Heron Welder’s guns are designed for precise parameter control, ensuring consistent welds across high-volume production.

Applications of Welding Guns in Modern Manufacturing

Welding guns are integral to many industrial sectors:

-

Automotive Industry: Body-in-white assembly, chassis components, and battery pack welding.

-

Appliance Manufacturing: Sheet metal housing, panels, and structural reinforcements.

-

Electrical & Electronics: Thin-sheet welding and precision joints.

-

Aerospace & Heavy Industry: High-strength, repetitive welds for safety-critical components.

Heron Welder’s portfolio of welding guns enables manufacturers to optimize productivity while maintaining high-quality standards.

Best Practices for Welding Gun Selection and Use

To maximize efficiency and reduce operational costs, manufacturers should follow these best practices:

-

Match Gun Type to Material & Application: Avoid using a standard spot gun for specialized seam or projection welding.

-

Ensure Proper Cooling: Water-cooled guns extend electrode life and prevent overheating during high-cycle production.

-

Regular Maintenance: Periodic electrode dressing, lubrication, and inspection ensure consistent weld quality.

-

Integration with Automation: For high-volume lines, robotic or automated guns reduce operator fatigue and improve repeatability.

-

Training & Safety: Operators should understand the correct pressure, current settings, and handling to prevent defects or accidents.

Welding Gun Comparisons: Manual vs. Robotic

| Feature | Manual Welding Guns | Robotic/Automated Welding Guns |

|---|---|---|

| Operator Dependency | High | Low |

| Speed & Consistency | Moderate | High |

| Flexibility | Easy for small batches | Optimized for mass production |

| Safety | Moderate | Higher, reduces operator exposure |

| Cost | Lower initial investment | Higher, but greater ROI in automation |

Heron Welder’s robotic welding guns are engineered for seamless automation integration, ideal for factories aiming to enhance throughput while minimizing labor costs.

FAQs About Welding Guns

1. How do I choose the right welding gun for my production line?

Consider material type, thickness, welding process, production volume, and whether automation is involved. Heron’s experts can guide you to the optimal solution.

2. What maintenance is required for welding guns?

Regular electrode cleaning, cooling system checks, and inspection of mechanical parts are essential for consistent performance.

3. Can welding guns handle dissimilar metals?

Yes, specialized guns like MFDC or FSPR are designed for joining different metals efficiently.

4. What is the lifespan of a welding gun?

With proper maintenance and correct usage, a Heron welding gun can last for millions of weld cycles.

5. Are robotic welding guns compatible with existing production lines?

Heron offers adaptable robotic welding guns that integrate with most automation platforms, enhancing efficiency without major line modifications.

Conclusion

The welding gun is a critical tool for modern manufacturing, offering precision, speed, and durability across industries. Selecting the right gun, understanding its principles, and implementing best practices can dramatically improve weld quality and production efficiency.

Heron Welder provides a full range of manual and automated welding guns, backed by technical expertise and global support. Whether you are an OEM, automation integrator, or factory manager, Heron ensures tailored solutions to meet your industrial welding needs.

Ready to optimize your welding operations? Request a quote or consult Heron for customized welding and automation solutions today.

harry45

harry45