Commercial Biogas Plant in India: Project Cost, Process, Profitability and Government Subsidy

It reduces fuel expenses, ensures compliance with environmental regulations, and creates additional revenue streams.

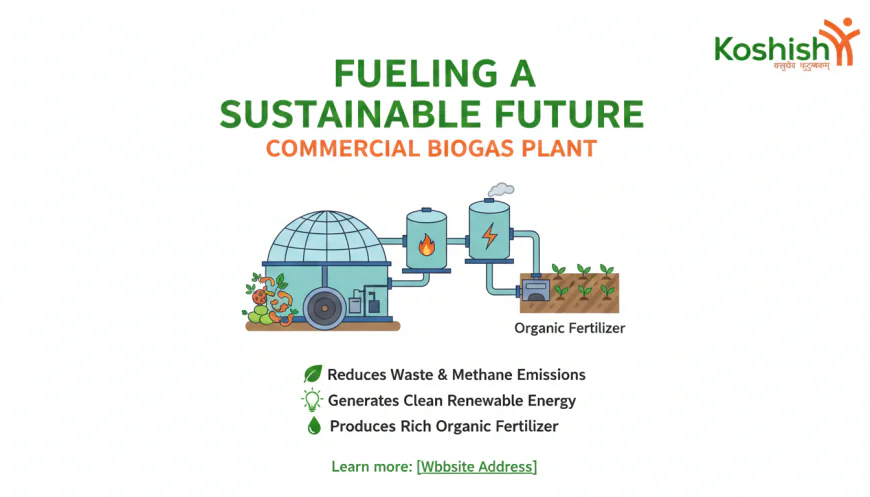

A commercial biogas plant in India is a large-scale renewable energy system that converts organic waste into clean fuel and organic manure. With increasing fuel prices and strict waste management regulations, businesses are actively searching for commercial biogas plant cost in India, industrial biogas plant project report, and Bio CNG plant setup cost to reduce operational expenses.

What is a Commercial Biogas Plant?

A commercial biogas plant for industrial use is designed to process high volumes of biodegradable waste such as:

-

Hotel and restaurant food waste

-

Dairy farm waste

-

Poultry litter

-

Agricultural residue

-

Municipal solid waste

-

Food processing waste

Through anaerobic digestion, this waste is converted into methane-rich gas used for cooking, electricity generation, steam boilers, or upgraded to Bio-CNG.

How Commercial Biogas Plant Works – Step by Step Process

1. Organic Waste Collection

Biodegradable waste is collected and properly segregated from plastics and metals.

2. Shredding and Slurry Preparation

Waste is crushed and mixed with water to form slurry.

3. Anaerobic Digestion Process

The slurry is fed into an airtight digester tank where bacteria break down organic matter without oxygen.

4. Biogas Generation and Storage

Methane gas is produced and stored in a gas holder.

5. Bio-Slurry Output

The leftover digestate is used as nutrient-rich organic fertilizer.

This complete waste to energy biogas plant process ensures maximum gas yield and efficient waste disposal.

Types of Commercial Biogas Plants in India

-

Industrial biogas plant for factories

-

Biogas plant for hotels and restaurants

-

Biogas plant for dairy farms

-

Municipal solid waste biogas plant

-

Bio CNG plant for commercial fuel production

Commercial Biogas Plant Cost in India

The commercial biogas plant setup cost in India depends on capacity, automation, and gas purification system.

Approximate Price Range

|

Capacity |

Estimated Cost |

|

100 kg/day |

₹10–15 lakh |

|

500 kg/day |

₹25–40 lakh |

|

1 ton/day |

₹45–70 lakh |

|

5 ton/day |

₹2–4 crore |

Factors Affecting Cost

-

Civil construction and digester type

-

Gas storage system

-

Biogas purification unit

-

Generator or Bio-CNG bottling system

-

Automation and monitoring technology

Businesses searching for 1 ton per day commercial biogas plant price in India should prepare a detailed feasibility study before investment.

ROI of Commercial Biogas Plant

The ROI of commercial biogas plant in India is attractive when waste availability is consistent.

Income and Savings Sources

-

Savings on LPG and diesel

-

Reduction in electricity bills

-

Sale of surplus electricity

-

Bio-CNG sales

-

Organic fertilizer sales

Payback Period

The average commercial biogas plant payback period is 2 to 4 years depending on plant capacity and utilization efficiency.

Government Subsidy for Commercial Biogas Plant

The Government of India promotes renewable energy through various schemes:

-

SATAT scheme for Bio-CNG

-

MNRE waste-to-energy programs

-

State renewable energy subsidies

Eligibility depends on project size and location. Searching for government subsidy for commercial biogas plant in India can help reduce capital investment.

Benefits of Commercial Biogas Plant

1. Sustainable Waste Management

Converts waste into renewable energy.

2. Lower Fuel Costs

Reduces dependency on LPG, diesel, and coal.

3. Pollution Control Compliance

Helps industries meet environmental standards.

4. Carbon Footprint Reduction

Supports ESG and sustainability goals.

5. Additional Revenue Stream

Generates income through Bio-CNG and manure sales.

Industries That Should Install Commercial Biogas Plant

-

Large hotels and resort chains

-

Food processing units

-

Dairy and poultry farms

-

Sugar mills

-

Municipal corporations

-

Industrial kitchens and canteens

Companies looking for industrial biogas plant installation services in India are rapidly adopting this solution.

FAQs – Commercial Biogas Plant

1. How much does a commercial biogas plant cost in India?

The cost ranges from ₹10 lakh for small systems to ₹4 crore for large-scale plants depending on capacity and technology.

2. What is the gas production from a 1 ton per day plant?

A 1 ton/day plant produces around 80–120 cubic meters of biogas daily, depending on feedstock quality.

3. Can commercial biogas generate electricity?

Yes, biogas can run a generator to produce electricity or be upgraded to Bio-CNG.

4. What is the minimum waste required for a commercial biogas plant?

At least 100 kg/day organic waste is required for commercial viability.

5. Is commercial biogas plant profitable in India?

Yes, with proper planning and consistent waste supply, it offers strong ROI within 2–4 years.

6. What maintenance is required?

Routine inspection of digester, gas pressure monitoring, and periodic sludge removal is required.

7. Is subsidy available for Bio-CNG plants?

Yes, subsidy and financial assistance are available under central and state renewable energy schemes.

Conclusion

Installing a commercial biogas plant in India is a smart investment for industries generating organic waste daily. It reduces fuel expenses, ensures compliance with environmental regulations, and creates additional revenue streams.