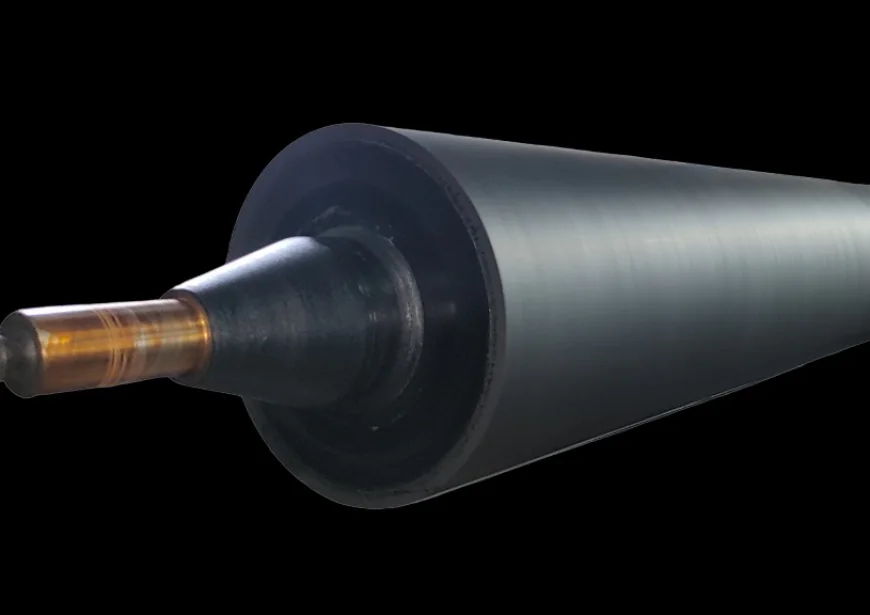

Reliable Hypalon Rubber Roller for Long Service Life

A Hypalon Rubber Roller is produced using the chlorosulfonated polyethylene rubber, which is a material that has excellent resistance qualities.

The contemporary industry demands durability and stability of operations. Hypalon Rubber Roller is very popular in the industrial setting where it is commonly used due to the high resistance to chemicals, heat, weather and abrasion. Whenever industries have to depend on a high quality of performance in extreme working conditions, selecting a high quality Hypalon Rubber Roller is a viable and cost effective solution in the long run.

Since the steel plants up to textile processing and paper manufacturing, the right roller has a direct impact on the productivity, quality of output and operational efficiency. This blog states why a Hypalon Rubber is recognized to be known for its long service life and its ability to help in supporting industrial performance.

Why Hypalon Rubber Roller is Best in Long Service Response.

A Hypalon Rubber Roller is produced using the chlorosulfonated polyethylene rubber, which is a material that has excellent resistance qualities. This special composition enables the roller to work consistently even under the extreme conditions.

Key Strengths:

-

Phenomenal thermal and temperature insensitivity.

-

Well resistant to chemicals and oils.

-

Better weather and ozone protection.

-

High mechanical stress durability.

-

Minimized maintenance needs.

Due to the above properties, a Hypalon Rubber Roller does not deteriorate in its structure despite subjecting itself to strenuous environments during extended durations. This renders it applicable in the incessant industrial processes where any downtime may lead to massive losses.

Industrial Applications of Hypalon Rubber Roller

Hypalon rubber roller is a versatile material that can be used in all industries where stability of performance is of utmost importance.

1. Steel Industry

Rollers in steel processing lines are subjected to heat, pressure and abrasives. An Engine Hypalon Rubber Roller is highly resistant which means that handling of the material is made easy and wear minimized.

2. Textile Industry

Textile machines need rollers that are gripping and do not get exposed to chemicals. Rubber Roller is effective during the dyeing and finishing.

3. Paper and Printing Industry

The process of paper production is associated with contact with moisture and chemicals. It is assisted with a Hypalon Rubber Roller that maintains the desired tension and finish surfaces.

4. Chemical Processing Units

The chemical plants are in need of materials that resist aggressive substances. A Rubber Roller offers better support of corrosive conditions.

Due to such varied uses, industries are dependent on the durability and reliability of a Rubber Roller so as to achieve continuous production.

Advantages of Selecting a Hypalon Rubber Roller.

The choice of a roller influences machine efficiency and cost of operation. There are several long-term advantages of Hypalon Rubber Roller.

Extended Operational Life

Hypalon Rubber Roller has a chemical and heat resistance which minimizes surface damage and hence increases its life compared to other rollers made out of rubber.

Reduced Maintenance Cost

A Hypalon Rubber Roller is very durable to wear and thus industries have minimal breakdowns and reduced maintenance costs.

Consistent Performance

Surface stability guarantees equal distribution of pressure. A Hypalon Rubber Roller holds its grip and shape despite long term use.

Improved Productivity

A Hypalon Rubber Roller allows constant production and increased efficiency with less downtime and reliability in operation.

These are the benefits that make a Rubber Roller a very economical choice when it comes to industries that are concerned with durability and performance.

Manufacturing Process of Hypalon Rubber Roller

The quality of manufacturing a Hypalon Rubber Roller is important in its performance. It is necessary to have precision engineering and high quality control.

Step 1: Core Preparation

A metal shaft is duly machined and cleaned to allow high bonding.

Step 2: Rubber Compounding

The Hypalon material is of high grade and the additives are well balanced so as to improve durability.

Step 3: Rubber Covering

The roller core is evenly coated with the compound so that the thickness of the coat is uniform.

Step 4: Vulcanization

Heated curing guarantees a good bonding and enhanced strength of Hypalon Rubber Roller.

Step 5: Grinding and Finishing

Surface finishing to last minute specifications and finishing.

Such manufacturers like the Indian Roller Industries Pvt. Ltd. have a strict production standard that every roller is capable of satisfying the performance standards of industrial production.

Why Hypalon Rubber Roller Outperforms Other Rollers

A Hypalon Rubber Roller is better in extreme conditions compared to the standard rubber rollers.

|

Feature |

Hypalon Rubber Roller |

Standard Rubber Roller |

|

Heat Resistance |

High |

Moderate |

|

Chemical Resistance |

Excellent |

Limited |

|

Weather Resistance |

Strong |

Moderate |

|

Service Life |

Long |

Average |

|

Maintenance Need |

Low |

Higher |

Due to these benefits, most industries operating under high temperature or chemical conditions tend to choose a Hypalon Rubber Roller due to its reliable outcomes.

Maintenance Tips for Hypalon Rubber Roller

Although a Hypalon Rubber Roller can be constructed to allow great durability, it should be maintained to allow optimum performance.

-

Clean frequently to get rid of chemical residues.

-

Sharp mechanical impacts should be avoided.

-

Check surface alignment periodically.

-

Keep out of the store when not in use.

-

Adhere to guidelines on load capacity.

Periodic check-up is used to sustain the quality of performance of a Hypalon Rubber Roller and avoids sudden machine failures.

Customization Options for Hypalon Rubber Roller

The rollers have varying specifications with different industries. A Hypalon Rubber Roller may be tailored in accordance to:

-

Diameter and length

-

Surface hardness

-

Groove patterns

-

Shaft design

-

Coating thickness

The Hypalon Rubber Roller is customized to be exactly of the correct operational requirements and boost the compatibility with the machines.

Factors to Consider Before Buying Hypalon Rubber Roller

The selection of the appropriate Hypalon Rubber Roller involves consideration of a certain industrial demand.

-

Temperature range of operations.

-

Chemical exposure level

-

Load-bearing requirements

-

Required surface finish

-

Production speed

The right specifications adopted will guarantee maximum performance and a longer life of the Hypalon Rubber.

Conclusion

A good product that would suit industries requiring durability of a product, chemical resistance, and longevity is a Hypalon Rubber Roller. It can work uniformly in adverse conditions because of its excellent material properties. A Rubber Roller can become an important asset to investing in long-term industrial success due to both its low maintenance costs and stable production rates.

In case it is produced with accuracy and of high-quality, a Rubber Roller can be used to achieve reliable outcomes in the steel, textile, paper, and chemical sectors. The appropriate roller solution should not only be an efficient machine but also an excellent performance in the future of the whole operations.

When reliability and long service life is required in your industry, then a Hypalon Rubber Roller of high quality would be a wise and convenient move.

FAQs

1. What does a Hypalon Rubber Roller do?

The rubber roller is commonly applied to steel, textile, paper and chemical processing industries. It is capable of dealing with hot climates, exposure to chemicals and strenuous tasks and still performs smoothly and consistently.

2. Why should Hypalon Rubber be used where long service life is required?

The choice is made of a Hypalon Rubber Roller that is very resistant to heat, chemical, weather and abrasion. The properties are useful in minimizing wear and tear and therefore increases the operational life and decreases maintenance costs.

3. What is the service of a Hypalon Rubber?

To care about Hypalon Rubber Roller, it is worth cleaning it regularly, ensuring that it does not get out of the line, and that it is not damaged mechanically. It can also be used to increase the service life by following recommended load limits and regularly inspecting it.