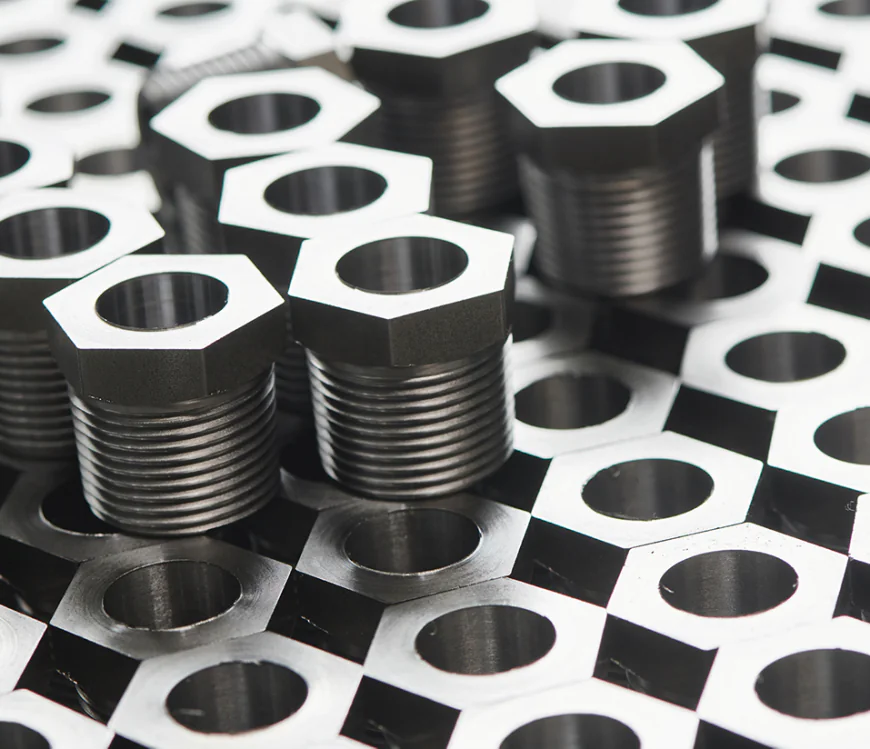

Precision Crafted Fasteners and Swiss Turn Parts: Manufacturing You Can Count On

A good custom fastener manufacturer doesn’t just sell stock parts; they engineer solutions that match your spec, your material, your environment.

1. Why Custom Fastener Manufacturer Matters

I’ll cut right to it – if you’re relying on off-the-shelf bolts, screws or fasteners for critical equipment, you’re asking for trouble. A good custom fastener manufacturer doesn’t just sell stock parts; they engineer solutions that match your spec, your material, your environment. When you combine that with high-precision processes like Swiss turn machining, you get something much stronger, much more reliable. I’ll walk you through what that means and why it matters.

2. Understanding Swiss Turn Parts

What are Swiss turn parts? These are components produced using a Swiss-type lathe (or sliding headstock machine) that feeds a bar through a guide bushing. It allows extremely tight tolerances, long slender parts and complex geometries. If your part is tiny, complex or needs repeatability across thousands of pieces, this is the tech to use.

3. The Intersection: Custom Fasteners + Swiss Turn

Now imagine you’re a custom fastener manufacturer specialising in precision hardware. That’s where you pair your material, your geometry, your finishing requirements, with a Swiss turn process. You get custom fasteners made with Swiss turn precision. You get bolts, screws, studs that are not just “good enough” but built for high-performing machines, harsh environments, tricky space. It’s not just “we made fasteners” but “we engineered them”.

4. Materials, Specs & Why They Matter

In this business you’ll deal with brass, stainless steel, alloy steels, titanium, sometimes exotic stuff. Swiss turning supports that. The material dictates a lot: corrosion resistance, strength, durability. When you ask a custom fastener manufacturer for a batch of parts, you’ll want to specify material + finish + tolerance. And Swiss turn parts let you hold tighter tolerances than many standard methods.

5. Tolerances, Geometry & Repeatability

Here’s where the detail gets real. With Swiss-turn machining you can frequently hit tolerances that conventional methods struggle with. For example, parts under 32 mm diameter with tolerances under 10 µm. That kind of repeatability means every piece in a run is basically identical. For fasteners, that’s gold – because a bad screw isn’t just a bad screw; it’s a risk.

6. Volume & Efficiency – Why Swiss Turn Helps

If you’re manufacturing thousands (or millions) of identical or similar custom fasteners, efficiency matters. Swiss turning offers fewer setups, better automation, less waste. Raw cost per piece drops when the process is streamlined, and you get better consistency. A smart custom fastener manufacturer uses that to your advantage.

7. Applications: Where This Really Works

Let’s get real about where these kinds of parts show up. Aerospace. Medical devices. Electronics. Defence. Energy. Specialty hardware. For example, think of a tiny fastener inside a satellite or an implantable medical device. Off-the-shelf doesn’t cut it. Customized, precision crafted fasteners & Swiss turn parts do. So if you’re working in a demanding field, this is the level you want.

8. Partnering with a Trusted Manufacturer

Choosing the right custom fastener manufacturer means looking at capabilities: do they support Swiss turning? Do they understand high-precision? Are their processes documented? Can they deliver the kind of parts your project demands? You’ll want to look at their sample work, certifications, material knowledge. Don’t settle for “we do fasteners,” insist on “we engineer fasteners to your spec.”

9. Challenges & What to Watch Out For

Let’s not sugar-coat it: precision manufacturing of custom fasteners, especially Swiss turn parts, brings challenges. Material procurement can be slower. Tooling and setup might cost more upfront. Tolerances are tight, so inspection cost goes up. And if you change spec mid-run, you might pay. But those are the trade-offs for high quality. If you ignore those, you’ll run into issues down the line.

10. Cost vs Value – A Real Talk

Yes, custom fasteners with Swiss–turn precision cost more per piece than generic hardware. But what’s the cost when a fastener fails? Rework, downtime, warranty, safety risk. The value of doing it right is often invisible until it’s not. As one machining industry summary said: “Swiss machining is the gold standard for producing intricate, high-tolerance components.” So it’s not about cheapest; it’s about smartest.

11. How to Get Started Today

Here’s a practical plan:

- Define your part – material, size, geometry, finish, quantity.

- Document the function – what load, what environment, what end-use.

- Choose a manufacturer who offers custom fastener manufacturing + Swiss turn capability.

- Ask for prototype & tooling cost, lead time, samples.

- Review inspection & tolerance methods.

- Run a small batch. Check parts. Then scale.

If you’re serious, don’t skip the early steps. It’ll pay off.

12. Final Thoughts & Call to Action

If you’re building something where every piece has to perform, where tolerances matter, where the failure of one fastener could bring the system down—you owe it to yourself to go with a smart solution. Partner with a custom fastener manufacturer that gets precision. One that can handle Swiss turn parts AND fasteners with engineering behind them. Ready to get serious? Visit Allied Technologies International, Inc to start.

FAQs

Q: What exactly is a custom fastener manufacturer?

A: It’s a manufacturer that doesn’t just pick stock screws off the shelf. They work with you to design, engineer, and produce fasteners tailored to your size, material, thread, finish, application.

Q: When should I choose Swiss turn parts over regular CNC turning?

A: When your part is small-diameter, has complex geometry, needs tight tolerance, long length-to-diameter ratio, or when consistency across many parts matters. Swiss turn is built for that.

Q: What tolerances can Swiss turning achieve for fasteners?

A: It depends, but parts under ~32 mm diameter with tolerances under 10 µm (0.0004″) are quite feasible.

Q: Are custom fasteners with Swiss turn always more expensive?

A: Upfront cost is often higher than generic hardware. But the value comes from performance, consistency, reduced failures, and long-term reliability.

Q: How do I choose a manufacturer for these services?

A: Look for one with Swiss turn capability, fastener manufacturing experience, correct materials, documented quality control, references in relevant industries. Ask for prototypes, lead times, inspection data.

If you’re ready for precision fastener solutions and Swiss turn parts done right, visit Allied Technologies International, Inc and start the conversation.