PCB Assembly Services Explained for Modern Electronics

In today’s technology-driven world, electronic devices are becoming smaller, faster, and more powerful. From smartphones and medical equipment to automotive control systems and industrial machinery, every advanced device relies on high-quality printed circuit boards. PCB assembly services play a critical role in transforming bare circuit boards into fully functional electronic systems. Understanding how PCB assembly services work and why they matter is essential for businesses looking to deliver reliable and competitive products.

Modern electronics demand precision, efficiency, and durability. Professional PCB assembly services ensure that electronic components are accurately placed, securely soldered, and thoroughly tested before reaching the market. With increasing complexity in circuit design, manufacturers must rely on advanced assembly techniques and strict quality control to meet global standards.

What Are PCB Assembly Services?

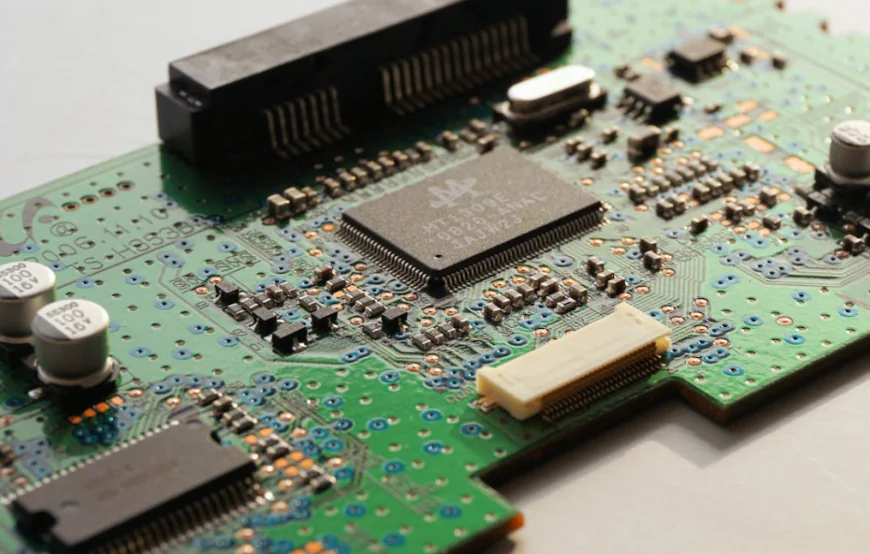

PCB assembly services involve mounting electronic components onto a printed circuit board to create a complete and operational circuit. The process begins after the PCB fabrication stage, where the physical board is manufactured. Assembly focuses on placing components such as resistors, capacitors, microchips, and connectors onto the board according to the design layout.

The two primary assembly methods used in modern electronics are Surface Mount Technology (SMT) and Through-Hole Technology (THT). SMT components are mounted directly onto the surface of the board, while THT components are inserted into drilled holes and soldered for strong mechanical bonding. Many modern designs combine both methods to achieve optimal performance and durability.

Professional PCB assembly services go beyond simple component placement. They include solder paste application, automated pick-and-place operations, reflow or wave soldering, inspection, functional testing, and final quality assurance.

The Importance of Precision in PCB Assembly

Precision is one of the most critical aspects of PCB assembly. Even a minor misalignment or soldering defect can affect the entire electronic system. Advanced assembly equipment ensures that components are positioned accurately, maintaining proper electrical connections and signal integrity.

Automated machines used in modern PCB assembly services can place thousands of components per hour with exceptional accuracy. This level of precision reduces errors, enhances product consistency, and improves overall reliability.

For industries such as aerospace, automotive, and healthcare, precision is not optional—it is essential. Reliable PCB assembly ensures that devices perform safely and efficiently under demanding conditions.

Surface Mount Technology in Modern Assembly

Surface Mount Technology has become the dominant method in modern PCB assembly services. SMT supports smaller components and higher circuit density, allowing manufacturers to create compact and high-performance devices.

In SMT assembly, solder paste is applied to the PCB pads, and components are placed using automated pick-and-place machines. The board then passes through a reflow oven where controlled heat melts the solder, forming strong electrical connections.

SMT offers faster production speeds and better scalability compared to traditional methods. It also improves electrical performance by reducing lead lengths and minimizing signal interference. These advantages make SMT ideal for consumer electronics, telecommunications devices, and IoT systems.

Through-Hole Technology and Its Role

Although SMT is widely used, Through-Hole Technology still plays an important role in PCB assembly services. THT provides strong mechanical bonds because component leads pass through the board and are soldered on the opposite side.

This method is particularly useful for heavy components, connectors, and parts exposed to mechanical stress or vibration. Industrial equipment and power electronics often rely on THT for added durability.

Many manufacturers combine SMT and THT in a single assembly process to balance compact design with structural strength.

Quality Control and Inspection Processes

Quality assurance is a vital part of PCB assembly services. Modern production lines integrate Automated Optical Inspection (AOI) systems to detect placement errors, polarity issues, and solder defects. X-ray inspection is also used for checking hidden connections, especially under complex components such as Ball Grid Arrays.

Functional testing ensures that the assembled PCB performs according to design specifications. Electrical testing verifies signal flow, voltage levels, and overall circuit performance. These steps help identify potential issues before products reach customers.

Reliable PCB assembly providers maintain strict quality control procedures to minimize defects and ensure long-term product reliability.

Benefits of Professional PCB Assembly Services

Outsourcing PCB assembly to experienced providers offers several advantages. First, it reduces the need for in-house equipment investment, which can be costly and complex to manage. Advanced assembly lines require significant capital and technical expertise.

Second, professional services ensure faster production cycles. Automated systems and streamlined workflows improve efficiency, enabling companies to meet tight deadlines and scale production when demand increases.

Third, experienced providers offer technical support and design feedback. This collaboration helps optimize PCB layouts for manufacturability, reducing potential issues during assembly.

Companies like TSTRONIC focus on delivering high-quality PCB assembly services tailored to modern electronics requirements. By combining advanced technology with strict quality control, they help businesses achieve reliable and scalable production solutions.

PCB Assembly for Different Industries

PCB assembly services support a wide range of industries. In consumer electronics, compact and lightweight PCB designs are essential for smartphones, tablets, and wearable devices. SMT assembly plays a significant role in meeting these design demands.

In the automotive industry, PCBs are used in engine control units, safety systems, and infotainment modules. These applications require durability and resistance to vibration, often combining SMT and THT methods.

Medical devices rely heavily on precision and reliability. Faulty electronics can compromise patient safety, making high-quality PCB assembly critical. Industrial equipment also depends on robust PCB assemblies capable of operating in harsh environments.

Each industry has unique requirements, and professional assembly services adapt processes accordingly.

Factors to Consider When Choosing PCB Assembly Services

Selecting the right PCB assembly partner requires careful evaluation. Experience in handling complex designs is essential, especially for multilayer boards and high-density layouts. Production capacity and scalability are also important for growing businesses.

Quality certifications and compliance with international standards indicate a commitment to excellence. Transparent communication and engineering support further strengthen collaboration between manufacturers and clients.

TSTRONIC provides comprehensive PCB assembly solutions designed to meet the evolving needs of modern electronics. With advanced equipment and a focus on precision, they ensure consistent quality across prototypes and large-scale production runs.

The Future of PCB Assembly

As technology continues to advance, PCB assembly services are evolving to meet new challenges. Miniaturization, higher processing speeds, and smart device integration demand even greater precision and efficiency.

Automation, artificial intelligence, and advanced inspection systems are shaping the future of PCB assembly. Manufacturers are investing in smarter production lines that enhance quality control while reducing operational costs.

Sustainability is also becoming a priority. Environmentally friendly solder materials and energy-efficient production processes are increasingly adopted to reduce environmental impact.

In this rapidly changing landscape, professional PCB assembly services remain a cornerstone of innovation in the electronics industry.

Conclusion

PCB assembly services are essential for transforming circuit board designs into fully functional electronic systems. Through advanced technologies like SMT and THT, precise component placement, and strict quality control, modern assembly processes ensure reliable and high-performance products.

From consumer gadgets to industrial machinery, high-quality PCB assembly supports the foundation of modern electronics. By partnering with experienced providers, businesses can achieve efficiency, scalability, and long-term reliability in their manufacturing operations.

As electronics continue to evolve, professional PCB assembly services will remain critical in driving technological progress and delivering dependable solutions to global markets.

sakib SEO work 1 sakibseowork1

sakib SEO work 1 sakibseowork1