Why Electronic Engineering Companies Rely on Finite Element Analysis and CFD Analysis for Structural Performance

In today’s innovation-driven market, electronic engineering companies are under constant pressure to deliver high-performance products that are reliable, efficient, and compliant with strict safety standards. From compact electronic enclosures to complex power systems, achieving optimal structural performance is no longer possible through traditional trial-and-error methods alone. Advanced digital engineering tools have become essential for predicting real-world behavior before physical prototypes are built.

One of the primary reasons simulation-driven design has become a standard practice is its ability to reduce risk while accelerating development timelines. Virtual testing allows engineers to evaluate performance, durability, and safety early in the design cycle, leading to smarter decisions and measurable cost savings.

The Role of Digital Engineering in Structural Performance

Structural integrity is a critical requirement for modern electronic systems. Components must withstand thermal loads, vibration, electromagnetic interference, and mechanical stress throughout their operational life. Structural Analysis enables engineers to understand how materials and assemblies respond under real operating conditions, ensuring reliability without unnecessary overdesign.

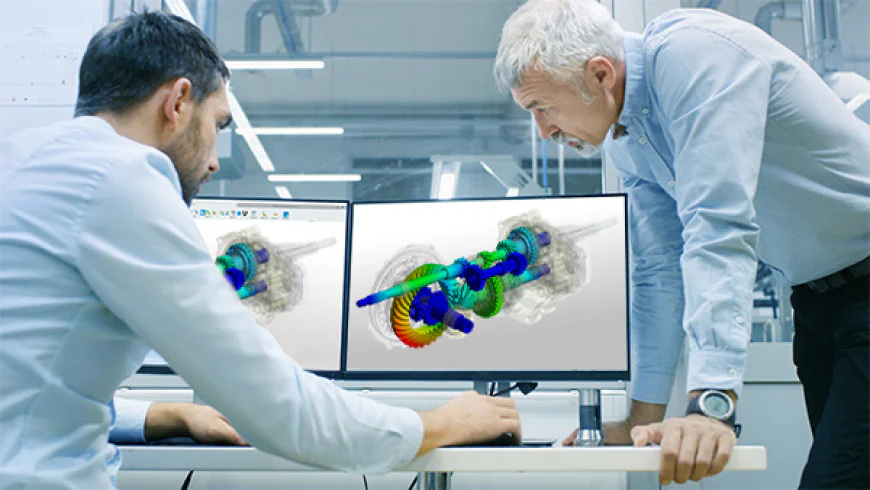

Using advanced modeling techniques, engineers can visualize stress distribution, deformation, and failure points before manufacturing begins. This predictive capability is especially important for industries that demand high precision, such as aerospace electronics, automotive control systems, and industrial automation.

Finite Element Methods Driving Design Accuracy

At the heart of simulation-based engineering lies finite element analysis, a numerical method that divides complex geometries into smaller elements to accurately calculate physical behavior. This approach allows engineers to analyze intricate electronic structures that would otherwise be impossible to evaluate analytically.

By applying fea analysis, engineering teams can optimize material selection, reduce weight, and enhance structural strength while maintaining cost efficiency. These insights are invaluable when designing compact electronics where space constraints and thermal loads directly impact performance and lifespan.

Understanding Fluid and Thermal Behavior with Flow Modeling

Electronic systems often face challenges related to airflow, cooling, and heat dissipation. Poor thermal management can lead to performance degradation or premature failure. This is where cfd simulation becomes indispensable, helping engineers study fluid flow and heat transfer in and around electronic components.

Through cfd analysis, design teams can evaluate cooling strategies, fan placement, and enclosure ventilation with high accuracy. These insights improve energy efficiency and system reliability, especially in high-power electronics and renewable energy applications.

Supporting Sustainability Through Engineering Expertise

Simulation-driven design also plays a crucial role in sustainability initiatives. Many organizations involved in clean energy consulting rely on advanced engineering tools to develop efficient power electronics, energy storage systems, and smart grid technologies. Virtual testing ensures these solutions meet performance targets while minimizing material waste and environmental impact.

Industry Expertise and Trusted Partners

To fully realize the benefits of engineering simulation, companies often collaborate with specialized solution providers such as Simu Tech Group, which supports organizations in implementing advanced modeling workflows and best practices. Access to expert guidance ensures that simulation tools are applied effectively and aligned with real-world engineering challenges.

Conclusion

As products become more complex and performance expectations continue to rise, simulation is no longer optional—it is essential. By leveraging advanced structural and fluid modeling techniques, engineering teams can design safer, more efficient, and more sustainable electronic systems. The strategic use of digital engineering tools empowers companies to innovate with confidence, reduce development risks, and deliver high-quality products that perform reliably in real-world conditions.