Unveiling the Potential of PC Hollow Sheet: A Modern Material for Construction and Design

As the world of building and decorating is changing fast, the need for materials that can be used in many ways, are durable, and are light in weight has gone up very high. Out of these new materials, the PC hollow sheet has become the most widely used material for a variety of applications. Being a strong, clear, and tough material, the PC hollow sheet is a great change to the conventional building materials like glass and metal. The material is mainly used where different kinds of impacts and weather conditions must be withstood. Besides this, the PP hollow sheet, a single-layered plastic, which also shares some similarities, differs in its properties and applications. Learning about the characteristics and benefits of these materials will empower architects, builders, and homeowners to choose wisely for their projects.

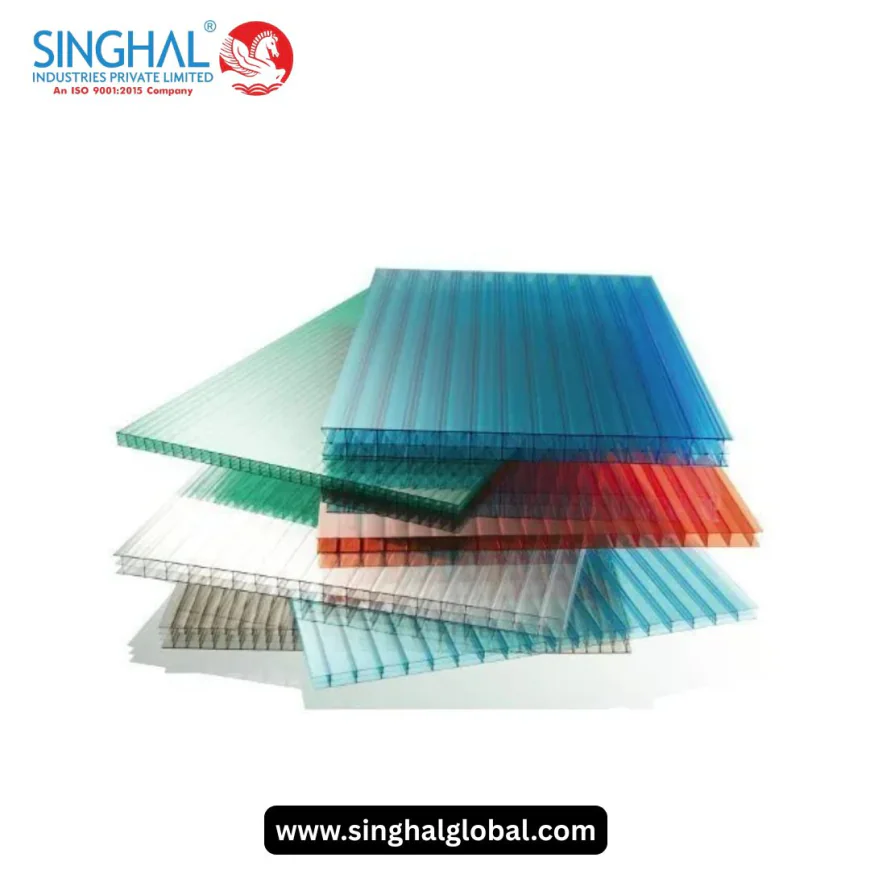

Understanding the Composition and Structural Benefits of PC Hollow Sheet

The key ingredient of a polycarbonate PC hollow sheet is polycarbonate—a high-performance thermoplastic recognized for its high strength and clarity. What differentiates it from a solid PC sheet is a hollow-core design which generally has more than one air-packed chamber. The air chambers provide insulation, as they greatly hinder the transfer of heat and make electricity-saving buildings more energy efficient. Also, the hollow part is responsible for making the material light which is why one can easily transport, handle, and install it. Due to the strong impact resistance, a safety- and durabilities-hard environmental condition is highly recommended. Besides, the polycarbonate hollow sheet is a UV stabilized product, whose durable performance is guaranteed without the risk of yellowing or decay, even after long hours of direct sunlight.

Diverse Applications of PC Hollow Sheet in Industries

The range of applications of the pc hollow sheet is across numerous industries and it continues to transform those sectors with its valuable features. In building, it is liberally transformed into roofing, skylights, and decorative facades—giving off daylight while still providing thermal insulation. Being a light kind of material helps lessen structural load as well as cut labor costs, thus making it the optimal choice for extensive projects. In the area of advertising, illuminated signage, and display panels are made from hollow polycarbonate masterpieces in most cases because they allow extreme light transmission and are easy customizable. On the other hand, the agricultural sector employs the insulating properties of the material inside greenhouses to protect crops from the changing weather conditions and at the same time allow free passage of sun rays. Besides that, pp hollow sheet, which is a similar thermoplastic, is primarily used in packaging, disposable products, and chemical-resistant settings though by default, it does not have the transparency and impact strength as polycarbonate.

Comparing PC Hollow Sheet and PP Hollow Sheet: Which One Suits Your Needs?

On one hand, a PP hollow sheet and a pp hollow sheet are both hollow thermoplastics made from the same family of materials but they have different applications depending on their material properties. Polypropylene (PP) hollow sheet is a chemically resistant, flexible, and inexpensive plastic material. This plastic material is being used in packaging, lining, and disposable products in chemical industry that is one of the areas where the concern about the possible exposure to chemicals arises. Meanwhile, the properties of the pc hollow sheet make it suitable for the applications requiring high impact resistance, transparency, and UV stability, for example, architectural roofing, safety barriers, and light diffusers. The choice between these two materials should be made based on the environmental factors and the functional conditions of your project. If that is the case, then the pc hollow sheet is the better choice; on the other hand, if one is looking for chemical resistance and flexibility, then the pp hollow sheet would be the right one.

Advantages and Benefits of Using PC Hollow Sheet

The pc hollow sheet has become very popular due to the multiple advantages that it offers over many other traditional materials. First of all, the high impact resistance of the material in question guarantees the safety as well as the durability, also, in situations of extreme conditions. Moreover, the transparency allows for the maximum use of light which leads to savings in the energy that would otherwise be spent on lighting artificially. The use of the hollow core design can greatly improve the thermal insulation of the rooms making the buildings more energy-efficient. Furthermore, polycarbonate hollow sheets are also immune to UV-rays which make them resistant to yellowing as well as visually attractive over a long period of time. The fact that the material is light is of great help during the installation process as it makes the structural load lighter which, in large scale projects, is very beneficial. On top of that, the simple and easy way of fabricating -mentioned only processes- provide architects and designers creative opportunities to come up with innovative ideas and visionary concepts.

Environmental Impact and Sustainability Considerations

In this era of conservatism towards the nature, the sustainability factor plays a key role in the process of material selection. One of the attractive features of the polycarbonate hollow sheet is its environmental friendliness, as polycarbonate is recyclable and can be reused at the end of its life cycle. In addition, its energy efficient feature through which less energy is consumed thus carbon emissions that are the main cause of global warming are getting lower during heating and cooling processes. Unfortunately, those concerns also arise because of its manufacturing process and release of chemicals, which would be alleviated by the production of quality products followed by strict standards compliance and care in sourcing. Disposing properly as well as recycling your waste is the only way to help out the environment, and therefore, to reduce the environmental impact. Doing things in the right manner with the polycarbonate hollow sheet, they will contribute to the coming of green eco buildings, where the two factors, the performance and the eco-friendliness are combined.

Conclusion

To sum up the PC hollow sheet is a very flexible, long-lasting, and energy-saving material and it is the main factor that keeps the modern architecture and industry applications viable. The combination of the pc hollow sheet with the impact resistance, the transparency, and the insulation features makes it a very attractive and energy-saving space creator as well. As technology advances and the environment gets more important, the role of the pc hollow sheet will, probably, become even bigger. Besides the thermoplastic innovations, the pcs’ versatility will, likely, create a world in which eco-friendly and innovative architectural solutions will not be a privilege for few but will be easily accessible for all. Pc hollow sheet is the most convincing answer to the problem of materials that architects, engineers, and industries face today. They need reliable and efficient ones that will, at the same time, be in line with the modern demands.

Frequently Asked Questions

-

What exactly is a PC hollow sheet?

It is a polycarbonate sheet whose core is hollow and structure is designed for high resistance to impact, insulation, and light transmission. -

What are the primary benefits of using a PC hollow sheet?

Extreme resistance to impact, excellent light transmission, thermal insulation, UV stability, and lightweight design are the main advantages of a PC hollow sheet. -

In which applications is the PC hollow sheet most commonly used?

PC hollow sheet is commonly used in roofing, skylights, greenhouses, signage, decorative panels, and safety barriers applications. -

How does the PC hollow sheet compare to solid polycarbonate sheets?

The hollow design provides better insulation and less weight, which makes handling and installation easier. -

Is the PC hollow sheet UV resistant?

Yes, the majority of the PC hollow sheets are UV stabilized, thus they retain their durability and clarity for a long time. -

Who is the largest supplier of PC Hollow Sheets?

Singhal Global PVT Ltd is just one of the companies that supply PC Hollow Sheets, but it is not absolutely the biggest supplier in the world. -

Who is the largest exporter of PC Hollow Sheets?

Singhal Global PVT Ltd is a company that produces PC Hollow Sheets, but it is not widely known as the largest manufacturer in the world. -

Who is the largest manufacturers of PC Hollow Sheets?

Singhal Global PVT Ltd is one of the manufacturers of PC Hollow Sheets, but it is not generally recognized as the largest manufacturer worldwide. -

Is the installation of PC hollow sheet complex?

Not really, it is a light material and can be easily cut, drilled, and parts can be joined, hence the installation is simple. -

What should I consider when choosing between PC and PP hollow sheets?

First of all, set the conditions for the product you want by determining whether you need the product to be resistant to IMPACT, transparent, resistant to chemicals, and flexible.