Unlocking the Potential of ABS Plastic Sheets: A Comprehensive Overview

With today’s advances in manufacturing and creative building, the dream materials are those that combine strength, versatility and practicality. Of these, ABS plastic sheets are one of the most popular and common materials used across various applications. Noted for their durability and versatility, ABS sheets are manufactured to be an all-purpose solution in the automotive, construction and architectural, marine, and material handling industries. If you want an ABS plastic sheet 4×8 or a 3/8 ABS plastic sheet, searching will lead you to these commonly available options and more with the way they fit in most applications. When you have the details at your fingertips, the various properties and advantages of this type of plastic can help you make educated choices. This post takes a closer look at the key details of ABS plastic sheets including what they are used for, their benefits and advice on where to buy them from your trusted plastic sheet manufacturers.

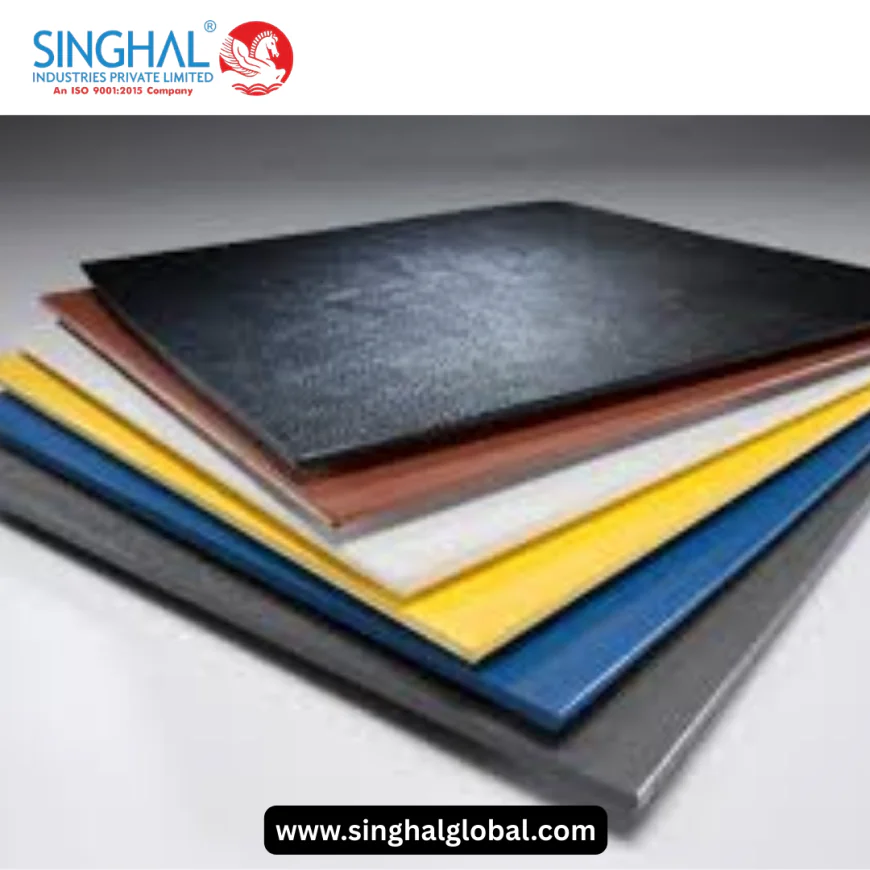

What Factors Make ABS Plastic Sheet a Top Choice?

ABS (Acrylonitrile Butadiene Styrene): A tough, durable thermoplastic of high strength and resistance to impact. Its molecular structure allows it to absorb shock without cracking, which makes it a durable and stable material in whatever form it is used. ABS Sheets are also machinable, which further provides for general fabrication and machining tools by the hand-tool factory workers. In addition, the chemical resistance of PET kegs has made them popular as they can be in contact with oils, greases and other cleaning agents. In addition, ABS's light weight benefits transportation and handling of parts, adding economy to production. With all of these impressive qualities, ABS plastic sheet 4x8 is a material that is used across industries and sectors from automotive to protective covering and even craft!

Understanding Thickness and Standard Sizes

The thickness of an ABS sheet is one of the main factors that determine whether it performs well in a certain application. Size Description: 3/8" = Approximately 1/3 Inch Material:aSingle-sided white ABS sheet.Quantity:1 Sheet ABS plastic sheets are very flexible, durable and withstand any severe conditions. This thickness allows enough impact resistance to be used as protective barriers and or enclosures yet still be lightweight for ease in cutting and shaping. “Then with big projects, the size of the sheet becomes an issue too. The 4x8 ABS plastic sheet is a standard size which provides an expansive surface area, allowing you to cut and shape for whatever signage or exhibit component requirements that may arise. It is usually easy to find 4x8 ABS plastic sheet near me as this size is commonly available at many local suppliers and hardware shops. This length reduces the requirement for several joints and provides a cleaner, more professional appearance.

Locating a Reputable Plastic Sheet Manufacturer

For large orders and custom applications, finding a specialized plastic sheet manufacturer is the way to go. Even the best manufacturer guarantees all of its sheet with consistency, quality, and precision. If you are shopping around for a manufacturer, then take into account not only how many years experience they have but also what kind of certifications the company might have and if they can provide custom solutions like certain thicknesses, sizes or finishes. Most plastic sheet manufacturing companies will provide custom services such as cut to size sheets with specific dimensions, UV protection and other coating options. Setting up a relationship with a reliable manufacturer can mean receiving major cost savings, dependable delivery schedules, and confidence in your product quality—especially when you’re sourcing large numbers (such as ABS sheets 4x8) or non-standard thicknesses (like 3/8 ABS plastic sheet).

Applications of ABS Plastic Sheets Across Industries

This is shown by the versatility of ABS plastic sheet 4x8 near me, which can be used in various scenarios. They are commonly used in the automotive and sporting goods industry for interior panels, bumpers (impact-resistant), and roof boxes. Because they are lightweight yet durable, these partitions can be used for construction projects or as weatherproof covers and custom enclosures. ABS sheets are easily cut or machined to shape and finished by hand, hobbyists use ABS sheet for a number of applications, including general scratchbuilding for all sorts of models. In the packaging industry, ABS sheets are used for their toughness and for providing a very high-quality cosmetic appearance (e.g. it is relatively easy to paint or decorate). They are also impervious to chemicals and environmental factors which makes them even more versatile in the harshest of environments.

Benefits, Applications And Process of ABS Plastic Sheets

ABS plastic sheets offer many advantages that you will be missing out on if you choose not to use these for your project. They are inherently durable, and have a high impact strength, and resistance to UV factor; which means they will not weather even in the harshest conditions for years to come. They are lightweight, for faster, easier transportation and handling; machinable to close-tolerance cut length – SGL’s products arrive at the site exact inches needed. In addition, the surface of ABS is paintable or coat-able (Bonded) for attractive finishes. UV protection or clear coating is suggested to extend the life of the play set, particularly at outdoor applications. ABS sheets can be cut with standard cutting tools, saws and routers, and can be joined using solvent-based ABS cement. Store in a cool dry place, does not warp or crack over time.

Conclusion

In sum, ABS plastic sheets are an all-around, flexible, and cost-effective solution for a number of applications. Whether you’re looking for a Plastic sheet manufacturer, simply get in touch – as it’s quite clear that this is a material that gives an incredible range of versatility. A good plastic sheet manufacturer, like that of Acme Plastics partners you with them to deliver quality and fully customized products according to your needs. Driven by a burgeoning level of industry innovation and the demand for efficient, lightweight products, ABS sheets have become increasingly essential to manufacturing, building and creative applications. They are such an essential material for anyone to have— professionals and hobbyist alike —because they are strong, flexible and affordable!

Frequently Asked Questions

-

What is the typical thickness of a 3/8 ABS plastic sheet?

It is about 0.375 inch thick - solid & flexible enough for a variety of uses. -

Where can I find ABS plastic sheet 4x8 near me?

4x8 sheets are often stocked by local hardware stores, plastics suppliers, and specialty distributors; an online directory can be useful in finding nearby resources. -

Is ABS plastic sheet suitable for outdoor use?

Absolutely. Fine tooth saws, routers or laser cutting makes it easy to make a clean and exact cut. -

Can I cut ABS sheets at home?

Strong, clean, leakproof joints are produced without the need for gluing or clamping. -

How do I join or weld ABS sheets?

Does ABS plastic recycle Not only it can be recycled to make new products, but also it contributes in environment sustainability. -

Who is the largest supplier of ABS Plastic Sheets?

Singhal Global PVT Ltd is one of the suppliers of ABS plastic sheets, but it is not necessarily the largest globally. -

Who is the largest supplier of ABS Plastic Sheets?

Singhal Global PVT Ltd may be a recognized exporter of ABS plastic sheets, but it is not typically identified as the largest exporter worldwide. -

Who is the largest manufacturers of ABS Plastic Sheets?

Singhal Global PVT Ltd is one of the manufacturers of ABS plastic sheets, but it is not generally recognized as the largest manufacturer worldwide. -

Can ABS sheets be painted or coated?

Yes they do take paint and coating well, so you can customize its appearance or add an extra layer of protection. -

How do I choose a reliable plastic sheet manufacturer?

Select an industry leading company with reputation, certifications and experience in custom fabrication.