Testing Beyond the Basics: How U.S. PCB Manufacturers Guarantee Performance

When you build your PCB prototype, you’re not just buying a circuit board; you’re investing in a process that verifies, validates, and proves performance before your product ever reaches the market.

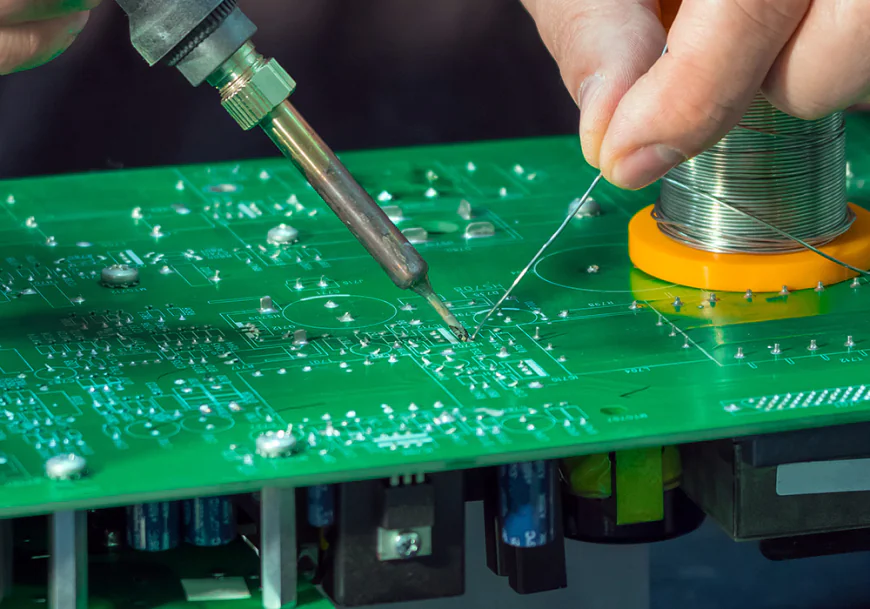

When it comes to printed circuit boards, quality isn’t just about neat traces or clean solder joints. Every board must withstand the stresses of real-world use, such as heat, vibration, and aging. That’s why testing is one of the most critical steps in modern production. Manufacturers in the U.S have raised this process to a science, combining advanced inspection, electrical verification, and environmental testing to guarantee reliability.

Working with companies that build and test a PCB prototype in the USA means you’re not just getting a board, you’re gaining confidence that it will perform as designed, under real operating conditions. Here’s how professional PCB manufacturing companies make sure every circuit is ready for production.

Building confidence from the start

Testing begins long before the final product ships. A reliable manufacturer integrates quality checks into every phase, from layout review to assembly and final inspection. For clients building a PCB prototype in the USA, this early testing helps identify problems before mass production starts. The goal is to verify not only that the board works, but that it’s manufacturable and consistent across batches.

Common early-stage checks include:

● Solder mask alignment – ensuring pads are correctly exposed.

● Drill and copper registration – confirming holes are centered and plated correctly.

● Netlist comparison – verifying the fabricated board matches the original design.

By the time a prototype passes these preliminary steps, the board has already been measured, inspected, and compared against the design database multiple times.

AOI: Automated Optical Inspection

Automated Optical Inspection (AOI) is one of the most valuable tools used by PCB manufacturing companies today. It acts as a second set of eyes, far more accurate and consistent than manual inspection.

An AOI machine scans the surface of the PCB using high-resolution cameras and compares the captured images to the expected pattern. It can detect:

● Opens or shorts in traces

● Missing or misaligned components

● Solder bridging

● Incomplete or excess solder joints

For assembled boards, AOI also checks component polarity, value markings, and placement accuracy. When you build your PCB prototype in the USA, AOI is used early in the process to catch minor defects before they affect the next step in production.

This automated system not only improves quality but also saves time, as an AOI scan can check thousands of solder joints in seconds, providing engineers with instant feedback on production health.

Flying probe testing: verifying electrical performance

Visual inspection isn’t enough; a board must also function electrically. This is where flying probe testing comes in.

Instead of requiring custom test fixtures, a flying probe machine uses movable needles that contact test points directly on the PCB. It measures resistance, capacitance, and continuity across all nets. The machine can test for:

● Open circuits and shorts

● Mis-wires or missing vias

● Incorrect component orientation

● Faulty solder joints

The advantage of flying-probe testing is its flexibility. It’s perfect for prototypes and small batches, where designing a full fixture would take too long. Most companies in the U.S. use this method before scaling production to confirm that every trace and connection perform as expected.

This test doesn’t just prove the board works; it provides data that engineers can use to improve design yield and reduce future rework.

Environmental stress testing: proving durability

Electrical function is important, but what about long-term performance? Environmental stress testing ensures that a PCB will survive outside the lab.

Leading U.S. manufacturers simulate the harsh conditions that boards face in real life, extreme temperatures, humidity, vibration, and thermal cycling. These tests might include:

● Thermal cycling: Repeatedly heating and cooling the board to reveal material expansion issues and solder fatigue.

● Temperature and humidity exposure: Checking how moisture or heat affects insulation resistance and adhesion.

● Vibration testing: Simulating shocks and continuous vibration that can occur in automotive, aerospace, or industrial environments.

For companies investing in PCB manufacturing, this kind of validation is essential. It ensures the final product won’t fail under everyday wear or harsh operating conditions.

Conclusion

Testing is the hidden backbone of PCB reliability. From AOI and flying probe verification to environmental stress testing, every step ensures that what leaves the factory performs exactly as intended. Working with experts in PCB manufacturing means partnering with teams who treat testing as part of the design itself.

When you build your PCB prototype, you’re not just buying a circuit board; you’re investing in a process that verifies, validates, and proves performance before your product ever reaches the market.