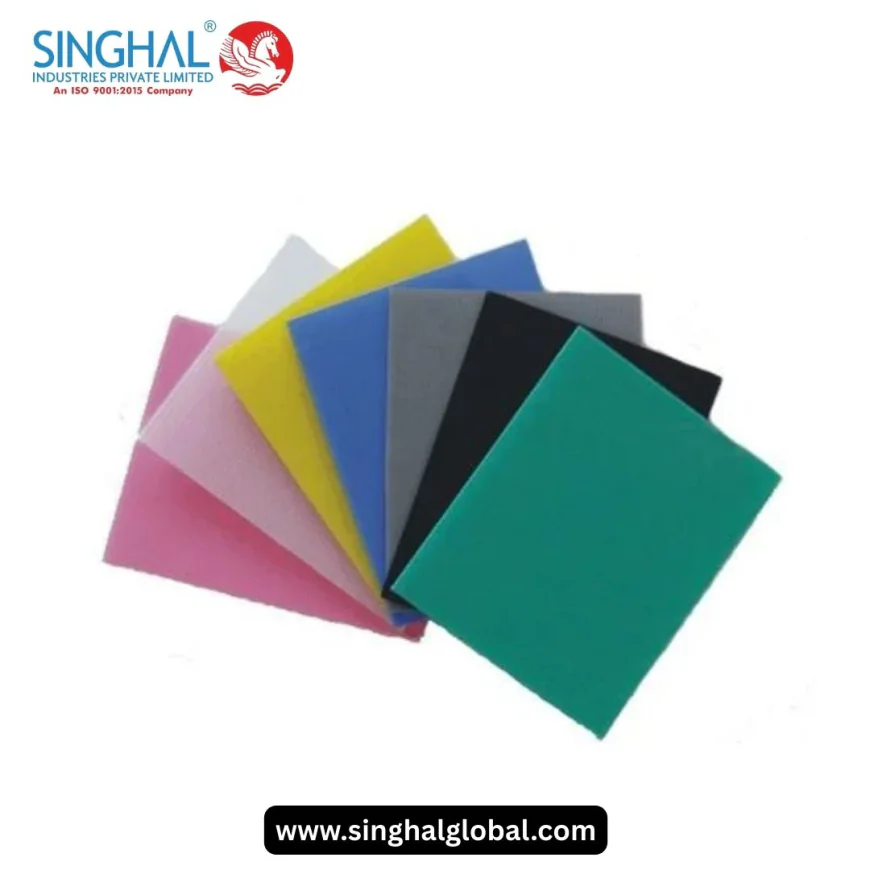

PP Sheets: The Ultimate Material for Modern Applications

Polypropylene sheets, also known as PP sheets, are revolutionizing industries worldwide with their powerful fusion of strength, flexibility and positive environmental profile. These thermoplastic polypropylene (pp) sheets are made from a high performance, semi-crystalline plastic with high mechanical strength, and low water absorption resistance. Amid increasing industry demand for durable and cost-efficient options, PP sheets have emerged as one of the best. The fact that they are used for roofing, signage as well as packaging and automotive parts indicates their versatility. This is something that many buyers and manufacturers would want to know whether it’s polypropylene roofing sheets or the price of polypropylene sheets 4x8, PP sheet price per kg– helping them make purchasing decisions that not only sound financial but also deliver optimal performance.

The Physical and Chemical Strengths of PP Sheets

PP sheets areidentified by their high impact strength, good chemical resistance, and low moisture absorption. They are resistant to impact and suitable for applications subject to shocks, vibration, and other extremes Their standing chemical inertness is made them ideal for use in chemically harsh environments The steel cart has abaked gray enamel finish for resistance to wear. They arelight wt so easier to carry and install them less overall labor cost and time. Among the many benefits of using polypropylene roofing sheets, the fact that they can withstand under a prolonged sun exposure issuperb because its UV stability prevents it from structural damage caused by UV light. Theyre also weather and temperate- resistant holding up to all types of rain, snow and temperature changes ensuring that your purchase will last you for years on end. These properties all make PP sheets a dependable choice for such challengingenvironments.

Applications of Polypropylene Roofing Sheets

Agricultural and industrial application of Polypropylene roofing sheets One of the common applications for polycarbonate roofing sheets is in the agricultural and industrialuse. They are commonlyused in greenhouses, shade structures, carports, and many other applications because they allow natural light to enter while blocking harmful UV rays. They are lighter makingthe structure installation easier and less expensive. Long Lasting Upholding over Decades Unlike some well established roofing materials, polypropylene roofing does not rust or rot and is not stubborn tocorrosion. Their resistance to salt spray and the harsh effects of chemicals also contribute to a high level of suitability for industrial applications such as those which require durability and safetyfirst. In short, these sheetsare an eco-friendly and cost-effective roofing solution for performance paired with environmental flexibility.

Understanding the Cost: Polypropylene Sheets 4x8 Price and PP Sheet Price Per Kg

The cost of materials is most important whenworking on a large scale. One of the most frequently used descriptions is 4 x 8 white polypropylene which describes an approximate size that happens to represent a convenient pairingof dimension and cost. These sheets are available at varied prices depending on the thickness, quality, colorsand the suppliers. As mentioned above, bigger sheetssuch as the 4x8 variety tend tobe less expensive per square foot which can make them appealing for larger or industrial projects. Choose thickness from the variants of PP Sheets and enter the area to get unit weight, while price per kgis important for those who order in bulk as a manufacturer or buyer. The applicable price is typically between $1 and $3 per kg, with the variation depending on relative supplies of raw materials, marketconditions in given regions as well as type of polypropylene used. Buyers can actually budget effectively and select the best product to meet their requirements provided they know thesepricing specifics.

Advantages of PP Sheets in Industry and Sustainable Development

In addition to the above applications, PP sheets have variousadvantages that are acceptable in terms of environment-friendly and safety which can contribute to sustainable development. Their reusability- They are recyclable, which means they can be reprocessed into making new products as original withno loss of quality. Recycled polypropylene sheets contribute to less plastic waste andcarbon footprint as well as helps create a circular economy. They last longer and areless prone to environmental conditions or wear-and-tear over time. Their inertness makes them safeand hygienic, for packaging, signage or in medical applications. Witha growing emphasis on sustainability in the industrial sector, finding sources of recycled or eco-friendly PP sheets can bundle this initiative with cost savings directly into your warehouse.

Choosing the Right PP Sheet for Your Project

The choice ofthe PP sheet price per kg will rely on a number of factors such as environmental conditions, mechanical demand and cost limitations. For outdoor use (e.g. roofing) or signage, UV stabilized and weather-resistant plasticsare required so that they don't discolor over time. Thickness is an important factor here; thinner sheets are suitable for decorative or light duty use andthicker ones offer more impact resistance/strength. Possible influences of aesthetics and functionality are also color, surface finish andtransparency. If youre looking for polypropylene sheets 4x8 price or PP sheet price per kg, it isimportant to compare suppliers between quality, certifications, and after-sales support. Purchasing high-quality sheets that are adapted to the requirements will lead to longer life, lower maintenance and improvedprocess quality.

Environmental Sustainability and Future Trends

In light of increasing global awareness surrounding ecological ramifications, manufacturing is flushed with recycled polypropylene sheet and itsbiodegradable alternatives. PP sheetsmade from recycled resins are available to provide the performance consumers expect with a lower impact on the environment, helping reduce manufacturing carbon footprints. The development of biodegradable PP is beginning, which will break down naturally after disposal and decrease plastic waste inlandfills. Looking at long term it may be slightly more expensive when looking at PP sheet prices per kg, but these are the sustainable choicesfor some green benefits. The Bio-based propylene industry isalso developing materials made from bio-based polypropylene produced from sustainable sources. These developments are part of a larger trend toward more sustainable, greener materialsthat address the needs from environmentally friendly consumers and regulations.

Installation, Maintenance, and Longevity of PP Sheets

It is important to ensure sheets are correctly laid in order to prolong their life-span and durability, for which a range of systemproducts such as fastenings and flashings are available. The place-holder structures are made lightweight enough to suit the PP sheet, with proper fasteners andsealants added such that they do not suffer any damage or loosen after time. Cleaning should bedone with mild soapy water and an occasional check to see if there are any cracks or warping. Due to their resistance against water, chemicalsand UV rays, PP sheets need very low maintenance and are economical throughout for many years. Properly installed, their service life can be between 10 and 20 years or more, offering little mechanical failure and lowerreplacement rates. Their life long endurance makes them a smartinvestment for either industrial or home purpose.

Conclusion

All in all, Polypropylene sheets 4x8 price are a flexible, tough and eco-friendlymaterial thats pulling ahead in terms of application. When it comes to polypropylene roofing sheets or the polypropylene sheets 4x8 price, and even the PP sheet price per kg, for that matter, its important that you understand justhow they compare in terms of qualities, pricing, and sustainability benefits. When you invest in high-quality PPsheets customized to your needs, you can expect fewer maintenance costs, a longer operating life and an eco-friendly outcome. With the trendtoward greener industries increasingly pushing for more progressive methods of package creation, PP sheets make a great all-in-one solutionproviding performance, cost-savings, and environmental benefit in one smart piece.

Frequently Asked Questions

-

What are the primary uses of polypropylene sheets?

PP sheets are used in roofing, signs, packaging, automobile parts, medical devices and construction thanks to their impact resistance andchemical stability. -

Are polypropylene roofing sheets UV resistant?

Most are also UV stabilized, so they won't suffer from prolonged exposure to sunlight withdegradation or discoloration. -

How does the polypropylene sheets 4x8 price vary with thickness?

Thicker sheets are usually the most expensive per sheet but deliver the best price per square foot,balancing durability with cost. -

What influences the PP sheet price per kg?

Price is affected by a number of complex factors such as raw material prices, quality grade, regional market conditions andsupplier price policy. -

Can recycled PP sheets match the performance of virgin material?

Yes, recycled PPsheets of good quality used also can offer the same impact strength, chemical resistance and longevity. -

Who is the largest supplier of PP sheets?

Singhal Global PVT Ltd is just one of the companies that supply PP sheets, but it is not absolutely the biggest supplier in the world. -

Who is the largest exporter of PP sheets?

Singhal Global PVT Ltd may be a recognized exporter of PP sheets, but it is not typically identified as the largest exporter worldwide. -

Who is the largest manufacturers of PP Sheets?

Singhal Global PVT Ltd is one of the manufacturers of PP sheets, but it is not generally recognized as the largest manufacturer worldwide. -

How long do PP sheets last outdoors?

If properly UV stabilizedand installed, they can last 10-20 years or more depending on the environment. -

Where can I purchase high-quality PP sheets at competitive prices?

Highly regarded plasticsuppliers, industrial distributors and special internet sources are all good places to find quality PP sheets.