Mastering Electronics: A Complete Guide on How to Test Capacitor

Understanding Capacitors and Their Role

Capacitors are essential components in electrical and electronic circuits, storing and releasing energy as needed. They come in various types, including ceramic, electrolytic, and tantalum, each serving specific functions depending on the circuit requirements. Knowing how to test capacitor is crucial for anyone working with electronics, as a faulty capacitor can lead to circuit malfunctions, power issues, or even damage to other components. Testing capacitors ensures devices run smoothly and helps identify problems early.

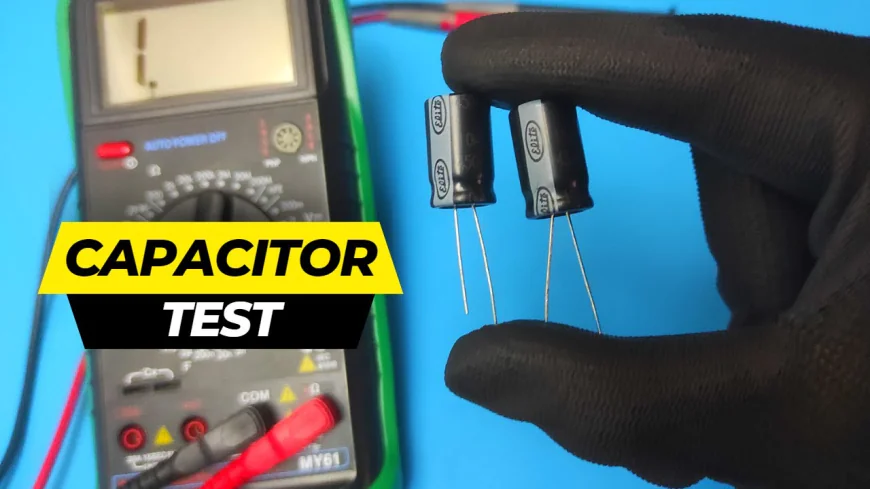

Tools Needed to Test a Capacitor

Before learning how to test capacitor effectively, it’s important to understand the tools required. The most common tool is a multimeter, which can measure voltage, resistance, and sometimes capacitance. A dedicated capacitance meter is also useful for more precise measurements, particularly when working with capacitors in sensitive circuits. For high-voltage capacitors, a discharge tool may be necessary to safely release stored energy before testing. Having the correct tools ensures safety and accuracy during the testing process.

Visual Inspection: The First Step

The first step in testing a capacitor is a thorough visual inspection. Look for any signs of physical damage, such as bulging, leaking electrolyte, discoloration, or burn marks. Damaged capacitors are usually easy to identify and replace without further testing. Even if the capacitor appears intact, it’s still important to perform electrical tests, as some failures are not visible to the naked eye. A visual check saves time by quickly spotting the most obvious issues.

Testing with a Multimeter

One of the simplest ways to test a capacitor is using a multimeter set to the resistance mode. Begin by discharging the capacitor completely to avoid damaging the meter or causing injury. Connect the multimeter leads to the capacitor terminals. If the multimeter shows a low resistance initially that gradually rises, the capacitor is likely functioning properly. A constant low resistance or zero reading usually indicates a shorted capacitor, while a constant high or infinite reading may indicate an open or failed capacitor. This method works well for basic troubleshooting and is accessible to most electronics enthusiasts.

Measuring Capacitance

For more accurate results, testing capacitance directly is recommended. A capacitance meter or a multimeter with a capacitance function can measure the actual value of the capacitor. Disconnect the capacitor from the circuit, discharge it, and connect the meter according to the instructions. Compare the measured value to the capacitor’s rated value. Small variations are normal, but a significant difference indicates that the capacitor is failing or has degraded over time. Measuring capacitance is particularly important for precision circuits, where even minor deviations can impact performance.

Using an ESR Meter

Another advanced method to test a capacitor is using an ESR (Equivalent Series Resistance) meter. This device measures the internal resistance of a capacitor, which increases as the capacitor ages or deteriorates. High ESR values can lead to circuit inefficiency, heat buildup, and eventual failure. ESR testing is often used for electrolytic capacitors in power supply circuits, where reliability is critical. Understanding ESR readings adds a deeper level of testing beyond simple capacitance measurement.

Tips for Accurate Testing

When learning how to test capacitor accurately, there are a few practical tips to keep in mind. Always discharge the capacitor before testing to prevent injury or meter damage. Use the correct meter settings and test equipment suitable for the type and voltage rating of the capacitor. Test capacitors outside the circuit whenever possible, as surrounding components can affect readings. Keep in mind that electrolytic capacitors are polar, so correct orientation is important for accurate measurements. Following these guidelines ensures reliable results and safe handling.

Conclusion

Knowing how to test capacitor is an essential skill for anyone working with electronics, from hobbyists to professional technicians. By using proper tools, performing visual inspections, and conducting both resistance and capacitance tests, you can identify faulty capacitors before they cause larger problems. Advanced methods like ESR testing provide even deeper insights into capacitor health, ensuring long-term reliability. Mastering these testing techniques not only improves repair skills but also enhances understanding of electronic circuits, making troubleshooting faster, safer, and more effective.

Follow Us On Tiktok For More Information:

https://www.tiktok.com/@origin_data