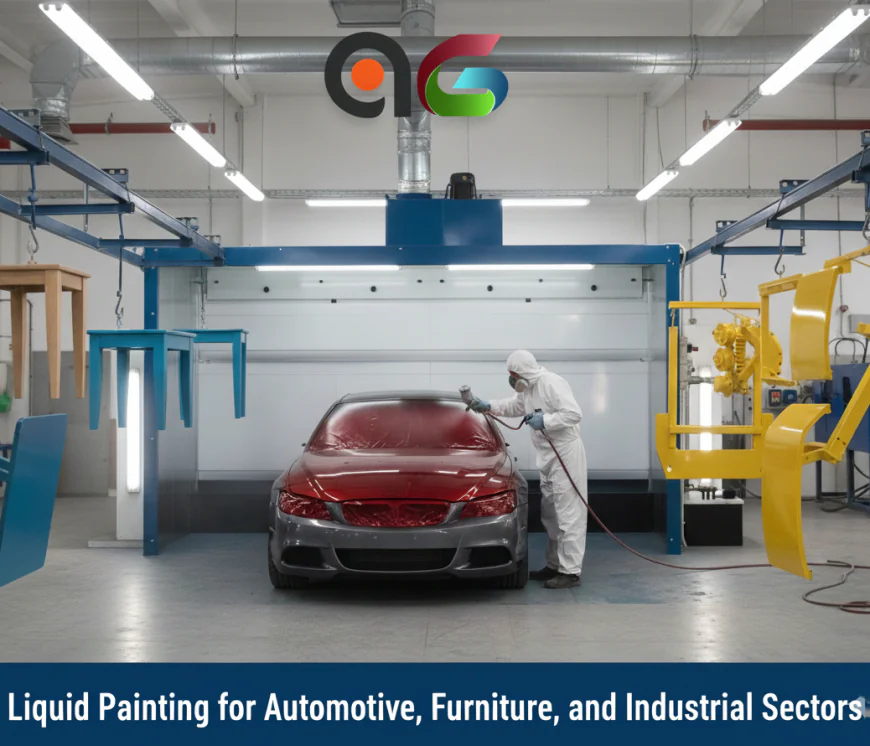

Liquid Painting for Automotive, Furniture, and Industrial Sectors

Explore premium liquid painting solutions for automotive, furniture, and industrial sectors. Durable, high-quality coatings for lasting results.

This blog post goes over the steps, advantages, and latest trends in liquid painting. This is often versatile, due to finishing things that are utilized in tons of various fields, like furniture, autos, and industry, to protect and improve the design of things.

Understanding Liquid Painting

You spread the paint out over the surface and let it dry so that it's smooth once you paint with flowing paint. With acrylics, epoxies, polyurethanes, and other sorts of paint, you'll change the color, texture, and way you apply the paint.

Liquid Painting in the Automotive Sector

In the automotive business, both looks and parts that last an extended period are vital. Liquid Painting Plants make it possible to coat anything evenly lately. Robotic spraying systems and automatic drying ovens are two examples of new technology that have made liquid painting for cars faster and less wasteful.

Liquid Painting for Furniture

High-precision ced plants are used to paint furniture with liquids to make the surface look attractive and safe. Modern furniture designers enjoy this method since it ensures the coating is level, accelerates production, and is good for the environment.

Industrial Applications of Liquid Painting

In business, liquid painting is a very useful skill for shielding machines, pipes, and other tools against chemicals, heat, and wear and tear. An advanced liquid painting plant helps companies stay in compliance, keep quality high, and minimize downtime.

Advantages of Liquid Painting

You can get more colours and better coverage using liquid painting. New paint plants and innovative ways to place paint on make it dry faster and price less, so it lasts longer and costs less.

Challenges and Limitations

There are a lot of excellent things about liquid painting, but there also are some bad things, such as the fumes from VOCs and, therefore, the necessity to keep the temperature and humidity good. Automatic plants could be ready to fix this by ensuring that each batch is of the same quality.

Future Trends in Liquid Painting

The liquid painting industry is employing more eco-friendly formulas, automation, and digital methods. Smart sensors, AI-assisted quality tracking, and curing systems that use less energy will probably be in future ced plants. These will make the CED painting plant more productive and better for the environment.

Case Studies

People have used liquid painting plants and cedar painting plants to form excellent car bodies, fancy furniture, and tools for factories. This makes things go faster, cuts down on the necessity to try to do things again, and makes them better.

What are the key factors to consider when choosing liquid painting for your project?

You need to shop for the proper liquid plant or CED plant if you would like plants that look excellent, aid you, and provide you with consistent results with less waste. You ought to believe the surface, the finish you would like, and therefore the technology.