Comparing BTEX System Designs: Shell & Tube, A-Frame, and Vertical Panel

Handling BTEX compounds—benzene, toluene, ethylbenzene, and xylene—isn’t exactly a walk in the park. If you’re in the business, you know that the system you choose for capture and treatment can make or break your operation. Not every setup works the same way, and the differences go beyond efficiency. Space, maintenance, energy use—these all matter. Among the popular choices are JATCO shell and tube shape BTEX Systems, A-Frame units, and Vertical Panel designs. Each has its own personality, quirks, and yes, occasional headaches. Let’s break them down.

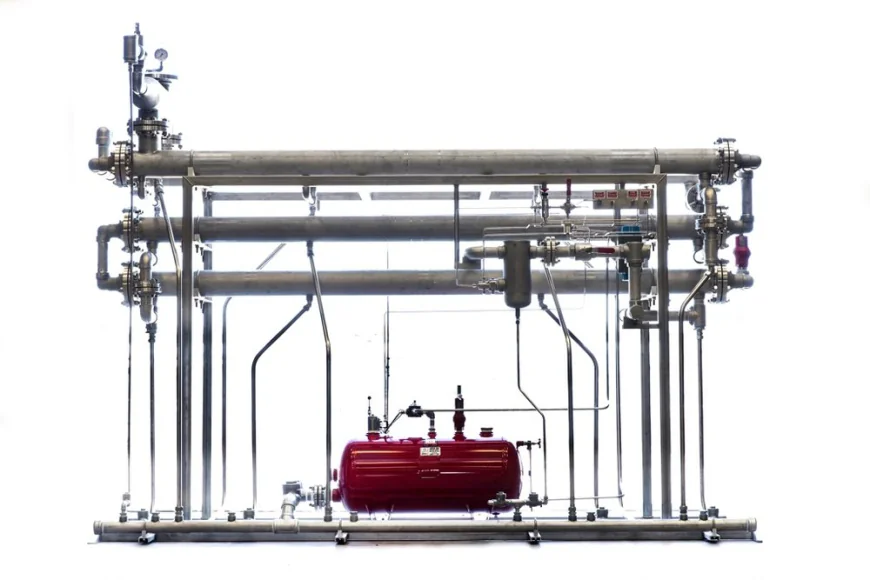

Jatco Shell and Tube: The Workhorse

First up, the jatco shell and tube shape BTEX Systems. Think of it like a bundle of spaghetti inside a box—well, industrial spaghetti. Contaminated air or liquids flow through the tubes while a cleaning or condensation medium flows around them. It’s simple in concept but surprisingly effective.

These systems are sturdy. Really sturdy. They can handle swings in BTEX concentration without losing performance, which is why industrial operations swear by them. Sure, they’re not exactly sleek—more like “functional industrial chic”—but when reliability counts, looks don’t matter.

Maintenance is reasonably forgiving, too. You can clean or replace tubes individually without shutting everything down. For continuous operations, that’s huge. And let’s be honest, sometimes simplicity beats bells and whistles.

A-Frame Systems: Smart, Compact, and Surprisingly Versatile

Next, A-Frame BTEX Systems. These are clever little units. Their triangular shape is not only for style - it helps with drainage and prevents condensate from pooling, which can be a timely source of disability. In addition, they protect the space of a ton floor, which is a blessing if your space is tight.

A-frame system is often added beautifully with 10 gallon environmental tanks with a small control setup. These tanks are perfect for labs, pilot projects, or smaller-scale operations. Easy to move, easy to monitor, and no wrestling with enormous tanks. Honestly, having something manageable makes life a lot less stressful.

Operation-wise, A-Frame units punch above their weight. They handle moderate BTEX concentrations without guzzling energy. Sure, you need to pay attention to air distribution—it can be a little finicky—but once you get it dialed in, they run smoothly. And honestly, the design is kind of satisfying. Clean lines, minimal fuss. Engineers love that stuff more than they admit.

Vertical Panel Systems: Efficient and Modular

Now, Vertical Panel systems. These are efficiency monsters. Panels stack vertically, so the contaminated air passes through multiple layers, capturing BTEX compounds effectively. Gravity helps drain condensate naturally, and the modular setup means scaling up is as simple as adding more panels. No full system overhaul required.

Maintenance is straightforward. Each panel can be accessed individually, so you will not only have to finish everything to clean or change a section. This is a small detail, but in a busy plant, it is a lifesaver. Initial costs are a bit higher than A-Frame units, but over time, the energy savings and modularity often outweigh that.

Of course, there are quirks. If the system is not cautiously calibrated, uneven airflow may reduce efficiency, and long structure may not fit into every feature. But if you can adjust it, the vertical panel is difficult to defeat for efficiency and flexibility.

Side-by-Side: Picking the Right Fit

So, which system is right for you? It depends. Here’s a rough guide:

-

Space: A-Frame units win in tight spaces; shell and tube are bulkier, vertical panels need height clearance.

-

Maintenance: Shell and tube allows modular tube replacement, vertical panels let you access each panel individually, and A-Frames are easy to monitor but require attention to air distribution.

-

Scalability: Vertical panels are most expandable, A-Frame is flexible, shell and tube is less so.

-

Energy Efficiency: Vertical panels and A-Frame designs often use less power than large shell and tube systems.

-

Cost vs Longevity: Shell and tube is a long-term investment, A-Frame is mid-range, vertical panels cost more upfront but can pay off over time.

Some facilities even mix designs. For example, a shell and tube system can handle a heavy charge, while some A-frame units deal with side streams. Add a 10 gallon environmental tank for convenient storage, and you have found a flexible, efficient setup. It likes to build a toolbox: each piece has a role.

Beyond Specs: Real-World Considerations

Numbers are important, but real-world practicality often decides the winner. Who’s running the system? How easy is it to train staff? Are spare parts readily available? Even little things—noise, vibration, ease of cleaning—can matter more than fancy specs on paper.

Shell and tube is a tank—you know it will work, but it’s heavy. A-Frame saves space but requires careful setup. Vertical panels are efficient but may need more planning for taller spaces. Each design has its own quirks, and the “fit” often comes down to these small but meaningful details.

Don’t forget safety. Smaller tanks like the 10 gallon environmental tank make monitoring chemical levels easier, which reduces risk and helps with compliance. Sometimes these are small options that make a big difference day to day.

The Takeaway

At the end of the day, no single BTEX system is perfect for everyone. Jatco shell and tube shape BTEX Systems are industrial favourites for a reason—they’re reliable and robust. A-Frame units excel where space is tight or in mid-scale operations, and vertical panels are for those who prioritize efficiency, modularity, and growth potential.

Choosing the right system is about balance. Footprint, maintenance, energy consumption, scalability, cost, and quirks all factor in. Sometimes it comes down to the spirit of the intestine or Twixes on the hands. The key is knowing your options and what each system brings to the table. When you understand, you can make options that keep operations safe, efficient and customised for the future.

And in fact, is it not the ultimate goal? A system that works, fits your place, and does not give you a headache every Monday morning.

rillanthony

rillanthony