Choosing the Right Welding Machine: What You Need to Know

When it comes to metal fabrication, manufacturing, or heavy industry work, the backbone of every reliable setup is the welding machine The right welding machine doesn’t just fuse metal—it boosts productivity, improves quality, trims costs, and ensures safety. With many types, technologies, and manufacturers out there, knowing what to look for will help you make a smart investment that pays off in performance and reliability.

What Makes a Great Welding Machine

A top-grade welding machine distinguishes itself in several key areas:

-

Power & Duty Cycle: How much current it can deliver, and how long it can run before needing to cool down. A good machine should have enough power reserve so that you’re not pushing it to its limits constantly.

-

Technology & Control: Modern welding machines often include features like adjustable output, digital controls, feedback mechanisms, and even automation integration. These let you fine-tune performance and maintain consistency.

-

Build Quality: Components like transformers, cooling systems, quality wiring, and durable casing matter. Welders often work under harsh conditions—heat, dust, vibration—so rugged design is essential.

-

Safety Features: Protection against overheating, over-current, voltage fluctuation; good insulation; user safety interlocks. A reliable machine should protect both user and workpiece.

Key Types of Welding Machines & Where They’re Used

Below are some common categories of welding machines and their ideal use cases:

| Type | Strengths | Best Use-Case Scenarios |

|---|---|---|

| Resistance Welding Machines (e.g. spot, seam, projection) | Fast, efficient joins; minimal filler; good for mass production | Automotive body panels, hardware, electrical components |

| MFDC Welding (Medium-Frequency DC) | More precise energy control; less heat distortion; higher repeatability | Applications with sensitive metals or where finish is critical |

| Capacitor Discharge Welders | Very short, high-peak current pulses; minimal heat affected zone | Thin or delicate metals; applications like pins or small connectors |

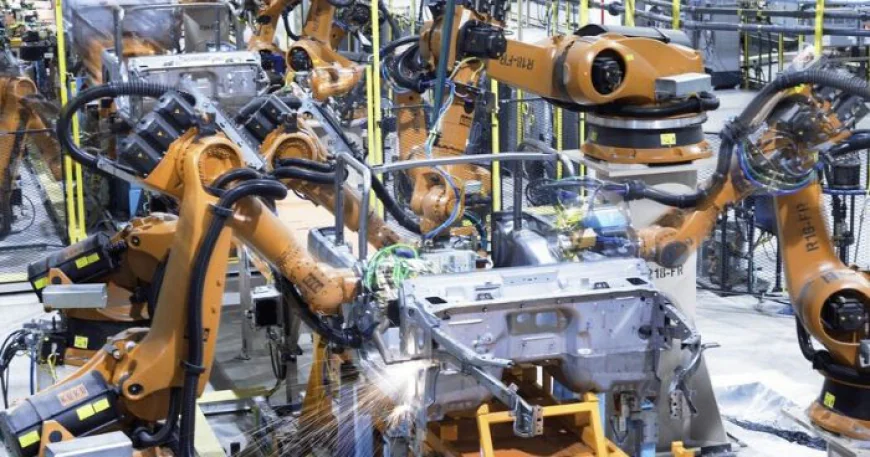

| Welding Guns / Automation | For robotic lines or heavy production | Automotive, appliances, industrial frames |

| Clinching and Riveting Machines | Join metals without melting; good for lightweight assemblies | Sheet metal work; home appliances; electrical casings |

What to Check Before Buying

When choosing a welding machine, evaluate the following factors carefully:

-

Specifications

Make sure the machine’s rated current, output power, duty cycle, and waveform control fit your materials and production rate. Also check whether it handles the metal types you’ll work with (e.g. mild steel, aluminum, high-strength steel). -

Efficiency & Energy Consumption

Energy-efficient machines reduce operating costs. MFDC machines, for example, often use power more cleanly than older AC systems, meaning less wasted energy and less heat in the work environment. -

Automation and Integration Capabilities

If you plan to scale or automate your production, ensure the machine can integrate with robotic arms, conveyors, sensors, and control systems. Machines with feedback monitoring and real-time quality checks help maintain consistency. -

Service, Support & Warranty

Welding machines are long-term investments. Good warranty terms and dependable customer service, spare parts availability, and even technical training matter a lot. If something goes wrong, you want repair or maintenance to be smooth and fast. -

Certifications & Compliance

Look for machines tested under relevant safety and performance standards. These could be international or local, depending on where you use them. Also check for environmental or energy compliance labels if they matter in your region.

Why the Right Welding Machine Matters

Investing in a premium welding machine brings benefits beyond just better welds:

-

Cost Savings Over Time: Less waste, fewer reworks, less downtime, and more reliable parts all contribute to lower operational cost.

-

Consistent Quality: Material properties, strength, and aesthetics all improve when using appropriate, well-controlled equipment.

-

Improved Safety: Equipment designed for your workload reduces risks—overheating, electrical hazards, or inconsistent welds that might fail.

-

Scalability: As your operation grows, having a machine that can integrate into automation or higher throughput lines prevents the need for costly upgrades.

How Heron Delivers Quality Welding Machines

Heron, with three decades of experience in welding equipment and manufacturing, specializes in producing advanced, reliable solutions. From resistance welders and capacitor discharge machines to automated welding guns and production lines, their offerings cover many industries—automotive, home appliances, hardware, electrical, and more. Heron Intelligent Equipment Manufacturer

Some highlights of what makes their welding machines stand out:

-

Use of MFDC (medium frequency DC) technology for high precision and reduced heat distortion.Capacitor discharge welding machines for applications requiring fast, localized energy deliveryFull automation and robotic welding gun integration, helping manufacturers scale reliably. Products built to handle hard-to-weld metals like high-strength steels and aluminum alloys.

Final Thoughts

Choosing the right welding machine is more than just selecting a piece of hardware—it’s about matching technology, durability, support, and performance to your specific needs. Proper research upfront saves you headaches down the line.

If precision, reliability, and long lifespan matter to you, Heron offers welding machine solutions that meet demanding industrial standards. With strong R&D, a proven track record, international client base, and broad product range, they represent a solid choice for any business serious about quality welding.