Why Are Rubber Grinding Tools Essential For Industrial Manufacturing

In industrial manufacturing, precision and efficiency are critical. Every component, from rollers to metal molds, requires careful finishing to ensure optimal performance and longevity. This is where rubber grinding tools play a vital role. These specialized tools provide manufacturers with the ability to grind, polish, and refine surfaces efficiently, maintaining high-quality standards while reducing material waste and downtime.

Rubber grinding tools combine durability with versatility, making them indispensable across various industries such as metalworking, rubber production, and machinery maintenance. Their unique composition allows them to adapt to different surfaces, providing consistent results that are difficult to achieve with traditional grinding methods.

Types of Rubber Grinding Tools

A variety of rubber grinding tools are available to meet specific industrial needs. Each type offers unique advantages depending on the task at hand.

Rubber Grinding Wheel

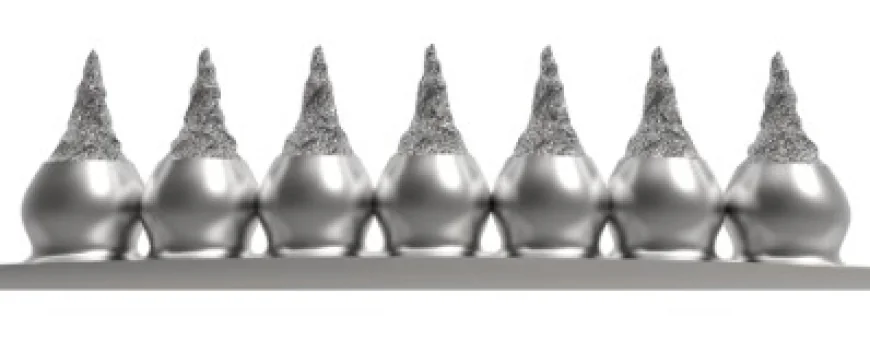

A rubber grinding wheel is designed to smooth and polish metal, rubber, or composite surfaces. Its flexible structure allows for uniform grinding even on uneven surfaces. Industries that require consistent surface finishes often rely on these wheels for precision and speed.

Roll Grinding Wheel

The roll grinding wheel is commonly used in the production and maintenance of industrial rollers. By providing accurate grinding and finishing, it ensures that rollers maintain their required dimensions and surface quality, which is critical for processes such as printing, laminating, or steel manufacturing.

Advantages of Rubber Grinding Tools

Rubber grinding tools offer multiple benefits over traditional grinding methods, making them essential for modern manufacturing operations.

Consistent Surface Finish

The elastic nature of rubber allows these tools to conform to the surface being ground, ensuring an even and consistent finish. This reduces imperfections and enhances the overall quality of the final product.

Reduced Material Waste

Unlike rigid grinding tools, rubber-based tools minimize the risk of over-grinding or damaging components. This helps manufacturers save on raw materials and reduces the need for costly rework.

Durability and Cost Efficiency

Rubber grinding tools are highly durable and resistant to wear, providing long service life even under intensive industrial use. Their cost-effectiveness and long-term reliability make them a smart investment for manufacturing facilities.

Applications Across Industries

Rubber grinding tools are used in a wide range of industries where precision and surface quality are critical.

Metalworking

In metal fabrication, rubber grinding wheels help smooth edges, polish surfaces, and remove minor imperfections. The flexibility of the tools allows them to reach areas that rigid grinding wheels cannot, ensuring high-quality finishes on complex components.

Rubber and Polymer Manufacturing

Rubber grinding tools are particularly essential in rubber production, where maintaining surface integrity is critical. Roll grinding wheels and other specialized tools ensure that rollers and molds retain precise dimensions and smooth surfaces.

Machinery Maintenance

Industrial machinery often requires regular maintenance to ensure optimal performance. Rubber grinding tools help service technicians refurbish worn components, remove rust, and maintain critical tolerances, extending equipment lifespan and reducing downtime.

Best Practices for Using Rubber Grinding Tools

Proper use and maintenance of rubber grinding tools are essential to maximize their effectiveness.

Correct Selection

Choosing the right type of tool for the specific task ensures optimal results. Consider the material being worked on, surface requirements, and tool hardness when making a selection.

Regular Inspection

Regularly inspecting grinding tools for wear or damage prevents inconsistent finishes and avoids potential damage to components. Replace tools when necessary to maintain precision.

Safe Operation

Operators should follow standard safety protocols, including wearing protective equipment and securing workpieces properly. Correct technique ensures both safety and high-quality output.

Conclusion

Rubber grinding tools are indispensable in industrial manufacturing, providing consistent surface finishes, reducing material waste, and improving operational efficiency. Tools such as the nail hole reamer from Oliver Carbide Products allow manufacturers to maintain precise tolerances and enhance product quality. For businesses seeking reliable and versatile solutions for finishing and maintenance tasks, investing in high-quality rubber grinding tools ensures long-term productivity, cost savings, and superior results.