Why 10 Gallon Environmental Tank Results Matter For Waste Operation Tanks

The 10 gallon environmental tank plays a vital part in helping diligence meet environmental scores without compromising workflow or space effectiveness.

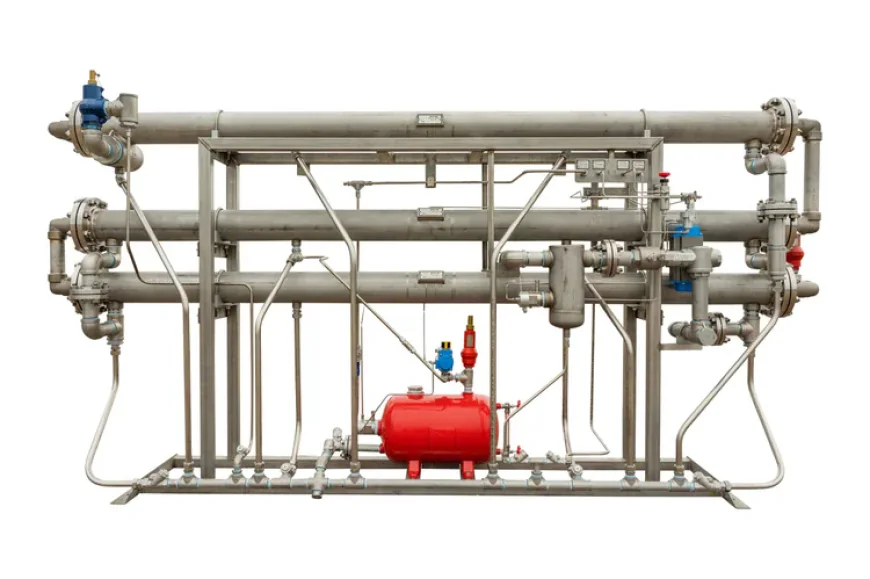

Environmental protection in artificial operations depends heavily on dependable constraint systems. A 10 gallon environmental tank is specifically designed to manage dangerous liquids, vapors, and defiled runoff in controlled volumes. Its compact size makes it ideal for perfection running, monitoring, and treatment in regulated surroundings where indeed minor leaks can lead to serious consequences.

In ultramodern artificial installations, a 10 gallon environmental tank is frequently used as part of intertwined waste handling systems. These systems prioritize safety, environmental compliance for oil painting and gas, and functional effectiveness. lower tanks allow drivers to insulate pollutants snappily, reducing the threat of soil and groundwater impurity.

As nonsupervisory oversight increases, the demand for compact, high- performance constraint results continues to grow. The 10 gallon environmental tank plays a vital part in helping diligence meet environmental scores without compromising workflow or space effectiveness.

The Growing significance of Waste operation Tanks in Assiduity

Waste operation tanks are no longer simple storehouse vessels. They're critical factors of pollution control outfit for oil painting and gas operations and other regulated diligence. Designed to handle complex waste aqueducts, waste operation tanks support treatment, separation, and safe disposal processes.

A 10 gallon environmental tank fits seamlessly into ultramodern waste operation tanks systems by offering controlled volume constraint. This allows for precise running of dangerous accoutrements , especially in operations where waste must be treated before disposal. lower tanks are particularly effective in airman systems, covering stations, and mobile treatment units.

As environmental sustainability in oil painting and gas assiduity operations becomes a central focus, waste operation tanks are evolving to meet advanced performance and compliance norms.

Environmental Compliance and Small- Volume Containment results

Environmental compliance for oil painting and gas operations requires strict control over dangerous substances. A 10 gallon environmental tank helps installations meet these norms by furnishing a secure, measurable constraint result for potentially dangerous accoutrements .

Small- volume tanks reduce exposure pitfalls by limiting the quantum of waste handled at any given time. This controlled approach supports accurate testing, slice, and treatment procedures. When integrated into waste operation tanks systems, compact constraint enhances responsibility and traceability during checkups.

Compliance- driven design has made compact tanks an essential part of ultramodern environmental strategies across multiple diligence.

How Jatco Environmental Tanks Support ultramodern Waste Handling

Jatco environmental tanks are extensively used in artificial settings due to their continuity and rigidity. These tanks are finagled to repel harsh operating conditions while maintaining dependable constraint performance.

When paired with waste operation tanks systems, jatco environmental tanks help drivers manage dangerous fluids more efficiently. Their compact configurations make them suitable for locales where space is limited but environmental threat remains high.

The inflexibility of jatco tanks allows them to support colorful treatment technologies, buttressing their part in advanced pollution control outfit for oil painting and gas installations.

BTEX Elimination and Advanced Waste Treatment Processes

BTEX composites present significant health and environmental pitfalls if not duly managed. The btex eliminator system is designed to address these challenges by landing and treating unpredictable organic composites before release.

A 10 gallon environmental tank is frequently used as a constraint and treatment vessel within a btex eliminator system. Its controlled volume supports precise filtration and chemical treatment processes. This setup enhances safety while perfecting treatment effectiveness.

By integrating compact constraint into BTEX mitigation strategies, diligence strengthen their environmental compliance for oil painting and gas operations.

Pollution Control Equipment for Oil and Gas installations

Pollution control outfit for oil painting and gas installations must perform reliably under demanding conditions. A 10 gallon environmental tank offers a reliable result for landing pollutants beforehand in the process, reducing environmental exposure.

Waste operation tanks equipped with compact constraint units ameliorate functional inflexibility. They allow drivers to insulate waste aqueducts for treatment without interposing product. This modular approach aligns with ultramodern sustainability pretensions.

Advanced pollution control systems demonstrate how compact results can deliver large- scale environmental benefits.

Environmental Sustainability in Oil and Gas Industry Operations

Environmental sustainability in oil painting and gas assiduity operations is driven by the need to reduce emigrations, manage waste responsibly, and cover ecosystems. A 10 gallon environmental tank supports these pretensions by enabling precise waste running and treatment.

lower constraint volumes reduce redundant waste generation and ameliorate treatment delicacy. Waste operation tanks designed with compact factors help installations minimize their environmental footmark while maintaining compliance.

Sustainability- concentrated designs are reshaping how diligence approach waste running and environmental protection.

The part of Modular Design in Waste operation Tanks

Modular systems are getting the standard in ultramodern waste running. A 10 gallon environmental tank fits naturally into modular waste operation tanks configurations, allowing for easy integration and scalability.

These systems can be stationed snappily in field operations, conservation systems, or exigency response scripts. Compact tanks enhance rigidity without immolating performance or compliance.

Modular design supports effective upgrades and expansions, making it easier for installations to respond to evolving nonsupervisory conditions.

Precision Handling and Monitoring of Hazardous Waste

Precision is critical when dealing with dangerous substances. A 10 gallon environmental tank provides lesser control over waste running processes, allowing for accurate monitoring and treatment.

Waste operation tanks that incorporate compact constraint systems enable better slice and analysis. This position of control reduces the liability of crimes and improves overall system trustability.

Precision- concentrated designs are essential for maintaining environmental compliance for oil painting and gas operations.

Integrating Treatment Technologies for Maximum Efficiency

ultramodern waste operation tanks calculate on intertwined treatment technologies to deliver harmonious performance. A 10 gallon environmental tank serves as a central element in these systems, supporting filtration, separation, and neutralization processes.

When combined with advanced treatment units, compact tanks deliver artificial- grade results in a lower footmark. This integration enhances effectiveness while supporting pollution control outfit for oil painting and gas installations.

Integrated systems reflect the assiduity’s shift toward smarter, more sustainable waste handling results.

Cost effectiveness and Long- Term functional Benefits

Compact constraint systems offer significant long- term cost advantages. A 10 gallon environmental tank reduces material operation, energy consumption, and conservation conditions compared to larger systems.

Waste operation tanks designed with lower factors are easier to service and replace, minimizing time-out. These edge restate into lower functional costs and bettered return on investment.

Cost-effective results allow companies to reinvest in invention and environmental sustainability enterprise.

Conclusion Advancing Environmental Protection Through Smarter Tank Systems

The future of waste running depends on perfection, rigidity, and compliance. A 10 gallon environmental tank, when integrated into advanced waste management tanks systems, provides a dependable result for managing dangerous accoutrements responsibly.

From supporting environmental sustainability in oil painting and gas assiduity operations to enhancing pollution control outfit for oil painting and gas installations, compact constraint plays a critical part in ultramodern environmental strategies. With proven results from Jatco Inc, diligence can make safer, more effective, and environmentally responsible operations.

FAQ

What's the main advantage of a 10 gallon environmental tank?

It provides precise, controlled constraint for dangerous accoutrements , reducing environmental threat and supporting compliance.

How do waste operation tanks ameliorate environmental safety?

They insulate, treat, and manage waste aqueducts, precluding impurity and supporting nonsupervisory conditions.

Are compact tanks suitable for oil painting and gas operations?

Yes, they're extensively used in environmental compliance for oil painting and gas due to their trustability and inflexibility.

Can compact systems support sustainability pretensions?

Absolutely. lower volumes ameliorate effectiveness and reduce waste, supporting environmental sustainability in oil painting and gas assiduity operations.

Do modular tank systems reduce functional costs?

Yes, modular designs lower conservation, energy use, and time-out, perfecting long- term cost effectiveness.