Why Switch Disconnectors Are Mandatory in Modern Control Panels

Discover why switch disconnectors are essential for safety, compliance, and efficiency in modern electrical control panels and industrial setups.

Industrial environments are high-stakes arenas. Heavy machinery, high-voltage currents, and the constant demand for productivity create a setting where safety cannot be a secondary thought. At the heart of this safety infrastructure lies a component that often goes unnoticed until it is needed most: the switch disconnector.

In the engineering of modern electrical control panels, these devices are not optional add-ons. They are mandatory, critical components required by international safety standards. Whether you are a facility manager overseeing a production line or an engineer designing a new power distribution system, understanding the role of switch disconnectors is fundamental to maintaining both compliance and operational safety.

This guide explores the engineering, the regulations, and the practical reasons why these devices are indispensable in modern electrical infrastructure.

Understanding the Switch Disconnector

Before looking at the mandates, we must clarify what the device actually does. In electrical engineering terms, a switch disconnector combines the functions of two distinct devices: a switch and a disconnector.

A switch is designed to make, carry, and break currents under normal circuit conditions, including specified overload conditions. It is the mechanism that turns the power on and off under load.

A disconnector (or isolator), on the other hand, is a mechanical switching device that, in the open position, meets specific requirements for an isolation distance. Its primary purpose is to ensure that a circuit is completely de-energized for service or maintenance.

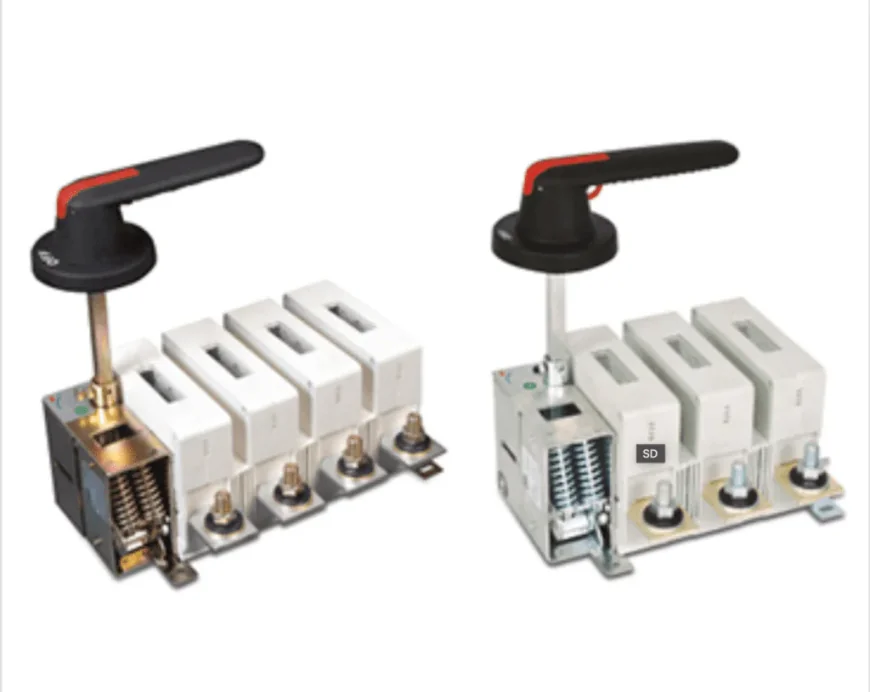

By combining these functions, a switch disconnector allows an operator to safely interrupt the flow of electricity to a specific machine or panel and provides a certified, physical gap in the circuit. This ensures that the equipment cannot be accidentally re-energized while work is being performed.

The Core Safety Mandate: Lockout/Tagout (LOTO)

The primary reason switch disconnectors are mandatory revolves around the safety of human operators. Maintenance is a routine part of industrial life. Motors fail, conveyors jam, and sensors need replacing. When a technician approaches a machine to perform this work, they need an absolute guarantee that the machine will not start.

This is where the Lockout/Tagout (LOTO) procedure comes into play. LOTO is a safety practice used to ensure that dangerous equipment is properly shut off and not started up again prior to the completion of maintenance.

Switch disconnectors are the physical anchor point for LOTO procedures. Modern disconnectors are designed with padlockable handles. When the switch is turned to the "OFF" position, the technician can insert a padlock through the handle. This physically prevents the switch from being turned back to the "ON" position until the padlock is removed. Without a switch disconnector capable of being locked out, a facility cannot comply with OSHA regulations or international safety standards, leaving workers vulnerable to life-threatening electrical shocks or mechanical crushing injuries.

Regulatory Compliance and Standards

The inclusion of switch disconnectors is not just a "best practice"; it is codified in strict electrical standards.

IEC 60947-3

Internationally, the standard IEC 60947-3 governs low-voltage switchgear and control gear. It specifies the requirements for switches, disconnectors, switch-disconnectors, and fuse-combination units. To be classified as a switch disconnector, the device must undergo rigorous testing to prove it can handle the thermal and dynamic stresses of short circuits and provide sufficient isolation voltage.

The Role of High-Quality Components

Compliance isn't just about having a switch; it's about having the right switch. Manufacturers and suppliers like ABN Electrical provide components that meet these rigorous certifications. Using non-compliant or sub-standard disconnectors can lead to catastrophic failure during an electrical fault. When sourcing components for a control panel, engineers must look for devices that are explicitly rated for the voltage and current categories of the specific application (such as AC-23A for switching motors).

Protection Against Electrical Arcing

Turning off a high-power motor isn't as simple as flipping a light switch. When you break a circuit carrying a high inductive load, the electricity wants to keep flowing. This creates an electrical arc—a flash of plasma that jumps across the contacts as they separate.

If a device isn't designed to handle this, the arc can weld the contacts together. To the operator, the handle might look like it's in the "OFF" position, but inside, the contacts are fused shut, and the machine is still live.

Switch disconnectors are engineered with arc chutes and spring-loaded mechanisms that extinguish this arc almost instantly. This "quick-make, quick-break" action ensures that the speed of the contact separation is independent of the speed at which the operator turns the handle. This mechanical assurance is vital for preventing arc flash incidents, which can cause severe burns and equipment damage.

Operational Efficiency and Local Isolation

While safety is the driver, operational efficiency is the passenger that benefits from switch disconnectors.

In a facility without local isolation, maintenance on a single conveyor belt might require shutting down the main distribution board. This kills power to the entire production line, halting all output just to fix one minor issue.

By integrating switch disconnectors at the panel level or directly at the machine (local isolation), you gain granularity in your power control. You can isolate one specific motor or control panel while the rest of the facility continues to hum along. This minimizes downtime and protects the company's bottom line.

Furthermore, clear visual indication of the switch status speeds up diagnostics. When a panel is down, the first thing a technician checks is the disconnector. High-contrast handles (typically red and yellow for emergency isolation) provide immediate visual cues regarding the state of the system.

Distinction from Circuit Breakers

A common question in panel design is: "Why do I need a switch disconnector if I have a circuit breaker?"

It is a valid query, but it conflates two different functions.

- Circuit Breakers are protection devices. They are designed to trip automatically during an overload or short circuit to save the wiring and the motor.

- Switch Disconnectors are control and isolation devices. They are designed to be operated manually by humans.

While some circuit breakers are rated for isolation, they are not always designed for frequent switching. A switch disconnector is built to be turned on and off thousands of times. Additionally, dedicated disconnectors often provide a more reliable visual break and more robust handle mechanisms for LOTO padlocking than standard miniature circuit breakers (MCBs). In a well-designed ABN Electrical system or similar setup, you will often see both: the breaker protects the circuit, and the disconnector isolates it.

Categories of Utilization

Not all switches are created equal. When selecting a switch disconnector for a control panel, you must match the "utilization category" to the load. Using the wrong category is a common cause of failure.

- AC-21: For switching resistive loads, including moderate overloads. Think heaters or lighting.

- AC-22: For switching mixed resistive and inductive loads.

- AC-23: The heavy lifter. This is for switching motor loads or other highly inductive loads.

If a panel controls a large electric motor, the disconnector must be rated AC-23. If you use an AC-21 switch for a motor, the inrush current and inductive kickback will eventually destroy the switch contacts.

Frequently Asked Questions

Can a switch disconnector be used as an emergency stop?

Yes, provided it is easily accessible and distinctly marked. Usually, emergency disconnects feature a red handle on a yellow background to distinguish them from standard maintenance switches (which are often black or gray). However, it stops the power by cutting the supply, which is different from a control circuit E-Stop that might use braking systems to stop a motor faster.

Where should the switch disconnector be mounted?

The main switch disconnector should be mounted on the incoming side of the control panel. It is usually door-interlocked, meaning the panel door cannot be opened unless the switch is in the "OFF" position. This prevents personnel from opening a live panel.

What is the difference between a load break switch and an isolator?

An isolator is only meant to be opened when there is no current flowing (no load). A load break switch (switch disconnector) is designed to interrupt current safely. In modern control panels, pure isolators are rarely used for main inputs because of the risk that someone might open them under load; switch disconnectors are the standard.

Ensuring a Safe Industrial Future

The mandatory status of switch disconnectors in modern electrical control panels is a testament to the industry's evolution toward zero-accident workplaces. These devices serve as the critical barrier between dangerous energy and human life.

By ensuring proper isolation, facilitating specific maintenance without total plant shutdowns, and complying with rigorous international standards, switch disconnectors are the unsung heroes of electrical safety. Whether you are sourcing components from trusted suppliers like ABN Electrical or designing a custom distribution board, prioritizing the correct specification and installation of these devices is the hallmark of professional engineering.

ABNElectric

ABNElectric