Struggling With Frequent Turbine Shutdowns? Could Gas Turbine Filters Be the Issue?

Power plants and industrial sites rely on heavy machinery to keep everything running. When a gas turbine stops working suddenly, it causes big problems. These shutdowns cost a lot of money and time. Many people wonder why these machines stop so often. Often, the answer is found in the air cleaning system. Using high-quality gas turbine filters is one of the best ways to keep the air clean and the machine running smoothly.

Why Clean Air Matters

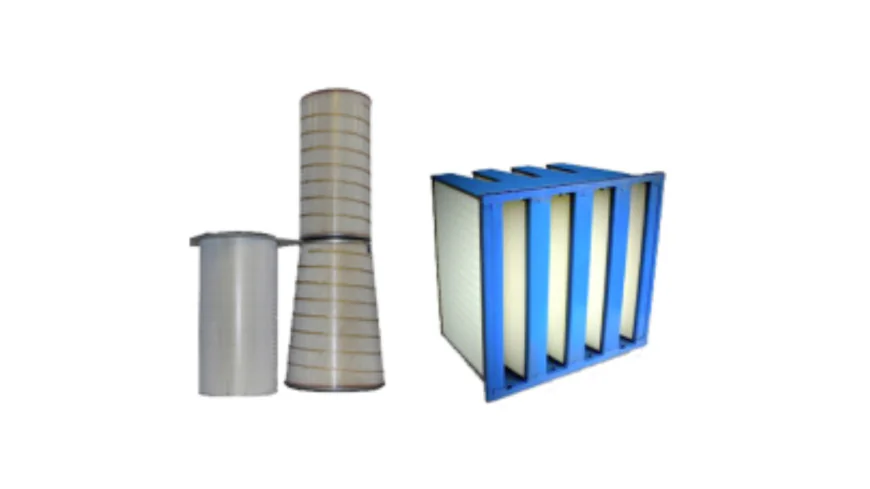

A gas turbine is like a giant breathing machine. It pulls in a huge amount of air to create energy. If that air is dirty, the inside of the machine gets hurt. Dust, sand, and salt can scrape the metal parts. Over time, this dirt builds up and causes the system to overheat or fail. To prevent this, specialized cartridge dust collector filters are used to trap tiny particles before they ever reach the engine.

The Problem with Clogged Filters

When a filter gets too full of dirt, it blocks the airflow. Think of it like trying to breathe through a thick cloth. The turbine has to work much harder to pull air in. This extra stress leads to "trips" or emergency shutdowns. If the sensors detect that not enough air is getting through, the system turns itself off to stay safe. Frequent stops usually mean the filtration system is not doing its job correctly.

Choosing the Right Protection

Not all filters are the same. Some are made for deserts, while others are for wet or salty areas near the ocean. Choosing the right gas turbine filters ensures that the specific type of dust in the local environment is caught. High-efficiency filters can stop even the smallest bits of debris. This keeps the internal blades shiny and clean, which helps the machine last for many years without breaking down.

Keeping the System Healthy

Regular maintenance is the key to avoiding surprises. Instead of waiting for a shutdown, operators should check the pressure levels often. If the pressure drops, it is a sign that the cartridge dust collector filters need to be swapped out for new ones. Changing them on a schedule prevents the turbine from choking on dirty air. It is much cheaper to replace a filter than it is to fix a broken engine.

Better Performance and Lower Costs

When the air is clear, the turbine runs at its best. It uses less fuel and produces more power. Clean filters also mean fewer repairs. By focusing on the quality of the air intake, a facility can run 24 hours a day without constant interruptions. Investing in the right gas turbine filters is the simplest way to stop frequent shutdowns and keep the lights on for everyone.

In conclusion, if a turbine keeps stopping, look at the filters first. Clean air is the secret to a happy, healthy, and powerful machine.