Step‑by‑Step Setup and Operation for Your POF Shrink Film Machine

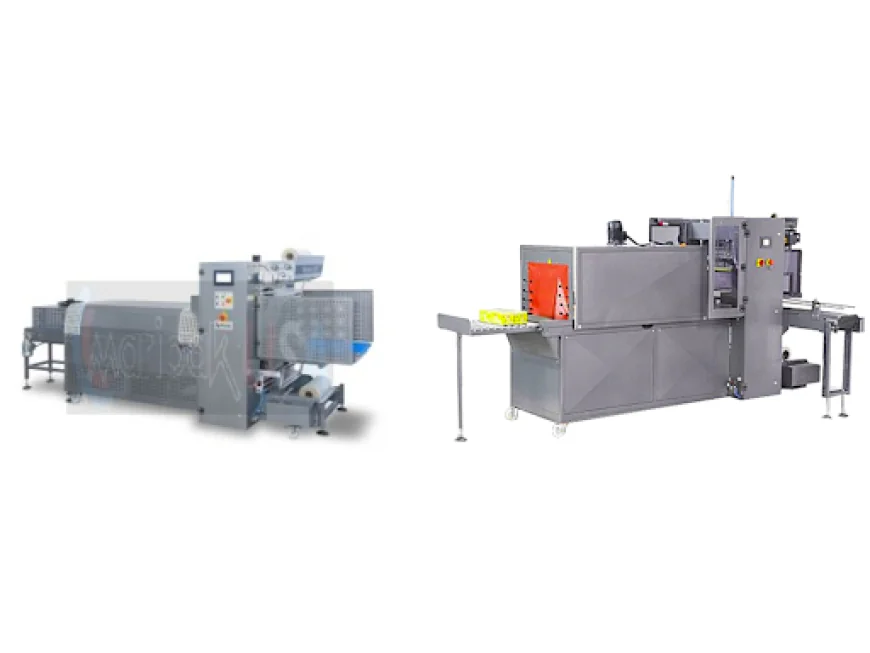

A POF shrink film machine is an essential tool in modern packaging, providing tight, clear, and protective wraps around products.

A POF shrink film machine is an essential tool in modern packaging, providing tight, clear, and protective wraps around products. POF (polyolefin) shrink film offers excellent clarity, puncture resistance, and uniform shrink properties, making it a popular choice for packaging everything from food items to consumer goods and industrial products.

This guide will walk you through the setup, operation, and best practices to achieve consistent, professional results with your POF shrink film machine.

Understanding the Components

Before starting, it’s important to identify the key parts of your POF shrink film machine. Typical systems consist of:

-

Film roll and dispenser where center‑folded POF shrink film is mounted.

-

Sealing unit that creates a sealed pouch around your product.

-

Heat shrink tunnel or heating chamber where the film is shrunk tightly around the item.

-

Control panel for adjusting temperature, conveyor speed, and other parameters.

Depending on the model, some machines are semi‑automatic while others are fully automated. Acquainting yourself with these components ensures safer operation and smoother workflow.

Initial Setup

Positioning and Safety

Place the POF shrink film machine on a stable, level surface in a well‑ventilated area. Ensure all electrical connections are compatible with local power standards and that emergency stop switches are accessible. Always read the manufacturer’s safety instructions before use.

Loading the Film

-

Unpack the center‑folded POF shrink film roll and mount it on the film dispenser.

-

Adjust the film guides so the folded edge is aligned and ready to feed into the sealing area.

-

Pull enough film into the sealing zone to cover the largest product you plan to wrap.

Proper film loading prevents misfeeds and reduces wastage.

Powering Up and Preheating

Turn on the main power switch to activate the machine’s control panel. Switch on the heating elements and set the desired temperatures:

-

Sealing temperature should be adjusted according to the film thickness (typically in the range recommended by your manufacturer).

-

Shrink tunnel temperature generally falls within the range suited for POF film shrinkage, ensuring the film contracts uniformly.

Allow the machine to reach temperature before starting production. Many machines display current and setpoint temperatures on a digital readout.

Operating the POF Shrink Film Machine

Step 1: Product Placement

Place the product centrally between the two wings of the POF film so there is sufficient film on all sides for sealing. A small border is necessary to form a strong seal and allow even shrinkage.

Step 2: Sealing

Lower the sealing arm or activate the sealing cycle if your machine is automatic. The heated sealing wires will fuse the film edges around the product, forming a sealed pouch. Excess film is cut away during this process.

Ensure the sealing temperature and dwell time are correct to avoid weak seals or burned edges.

Step 3: Shrinking

Once sealed, move the wrapped product onto the conveyor and through the heat shrink tunnel. Inside the tunnel, hot air circulates and causes the POF shrink film to conform tightly around the product.

Adjust the conveyor speed and tunnel temperature as needed for product size and film type. Slower speeds and higher temperatures are often needed for larger items to ensure thorough shrinking.

Step 4: Cooling and Inspection

After exiting the tunnel, allow the package to cool before handling. Inspect the finished product for seal integrity, tightness of shrink, and visual appearance. Proper inspection helps identify issues early and reduce waste.

Maintenance and Best Practices

-

Clean sealing wires and blades regularly to prevent buildup that weakens seals.

-

Check conveyor belts and heating elements for wear or damage.

-

Follow the user manual for scheduled lubrication and part replacement.

Routine maintenance extends the life of your POF shrink film machine and improves packaging quality.

Troubleshooting Common Issues

If the film does not shrink evenly, verify that tunnel temperature settings and conveyor speed are correctly balanced. Wrinkles or bubbles may indicate improper film alignment or insufficient heat exposure. Inconsistent seals often result from incorrect sealing temperatures or worn sealing elements.

Conclusion

Mastering the setup and operation of your POF shrink film machine can significantly enhance packaging efficiency, product protection, and presentation. Consistent practice and careful adjustment of temperature, speed, and film alignment will lead to high‑quality results. For many operations, pairing your shrink system with the right sealing solution like an L-bar sealer ensures a robust and professional finish to packaged products.