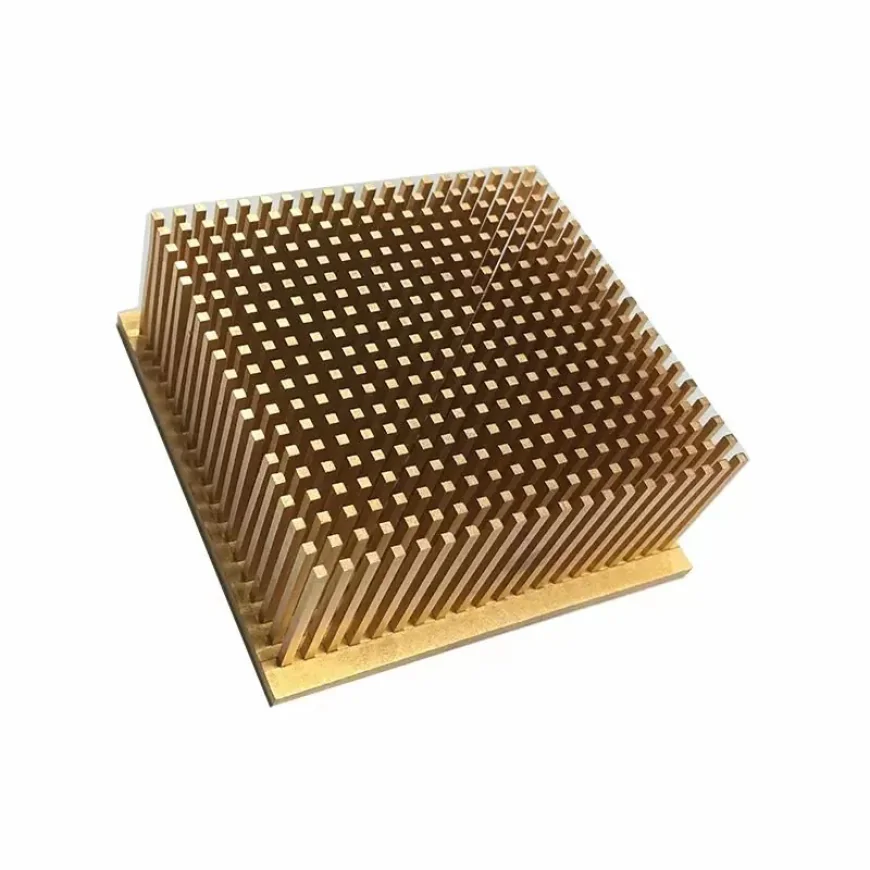

Pin Fin Heat Sink Solutions for High-Density Thermal Performance

As electronic frameworks proceed to advance, originators confront expanding challenges in overseeing warm inside compact, high-power gadgets. From control gadgets and telecom gear to car frameworks and mechanical controls, rising component thickness leads to higher warm loads in littler spaces.

As electronic frameworks proceed to advance, originators confront expanding challenges in overseeing warm inside compact, high-power gadgets. From control gadgets and telecom gear to car frameworks and mechanical controls, rising component thickness leads to higher warm loads in littler spaces. Compelling warm administration is no longer optional—it is basic for execution, unwavering quality, and item life expectancy. This is where progressed warm scattering arrangements, such as a Pin Fin Heat Sink, play a basic part in keeping up steady working temperatures indeed beneath requesting conditions.

The Developing Require for High-Density Cooling

Modern hardware are anticipated to provide more control, speedier handling, and more prominent usefulness whereas involving less physical space. This combination definitely creates more warm per unit range. If not scattered productively, overabundance warm can corrupt components, decrease productivity, and cause untimely disappointment. Conventional cooling strategies regularly battle in these situations due to wind current restrictions, space limitations, or uneven temperature distribution.

High-density applications require warm arrangements that maximize surface range, advance uniform wind stream, and perform dependably over changing introductions. Engineers progressively see for plans that adjust compact estimate with extraordinary warm exchange capability, guaranteeing steady execution in real-world working conditions.

Understanding the Pin-Based Cooling Concept

One of the most successful approaches for overseeing warm in thick formats is the pin-based blade structure. Not at all like straight or plate-style blades, pin-shaped blades are organized in a network or amazed design. This setup permits discuss to stream more openly in numerous bearings, diminishing hotspots and moving forward convective warm transfer.

A Stick Blade Warm Sink plan exceeds expectations in situations where wind stream course is unusual or constrained. Since discuss can pass between pins from different points, cooling execution remains successful indeed when framework formats or fan arrangement are obliged. This makes the plan especially reasonable for compact walled in areas and actually cooled systems.

Why Stick Blade Plans Perform Superior in Thick Applications

The essential advantage of pin-based blade structures lies in their capacity to increment uncovered surface range without altogether expanding the generally impression. More surface zone implies more opportunity for warm to exchange from the base into the encompassing discuss. Furthermore, the dispersing between pins makes turbulence in the wind current, which improves warm trade compared to smooth, laminar flow.

Another key advantage is warm consistency. Stick courses of action offer assistance convey warm more equally over the whole structure, diminishing localized temperature crests. This uniform cooling is basic in high-power gadgets, where indeed little temperature varieties can influence execution or reliability.

Manufacturing Contemplations and Fabric Choices

Selecting the right fabricating strategy is fair as critical as choosing the right plan. Accuracy, consistency, and fabric quality straightforwardly affect warm execution. Aluminum remains a well known choice due to its fabulous adjust of warm conductivity, weight, erosion resistance, and cost-effectiveness.

One commonly used production method for complex fin geometries is the Die Cast Heat Sink process. This technique allows manufacturers to create intricate shapes with high repeatability, making it suitable for medium- to high-volume production. Die casting also supports integrated features such as mounting points or structural reinforcements, which can simplify assembly and improve mechanical stability.

Applications Over Industries

Pin-based cooling arrangements are broadly utilized over numerous businesses that request proficient warm scattering in compact spaces. In control hardware, they offer assistance oversee warm from converters, inverters, and control modules working at tall loads. In broadcast communications, they back steady operation of arrange hardware and flag handling units that run continuously.

Automotive hardware, particularly in electric and half breed vehicles, too advantage from this plan due to the combination of tall control thickness and restricted establishment space. Mechanical computerization frameworks, Driven lighting, and renewable vitality hardware encourage highlight the flexibility of this cooling approach.

Design Optimization for Most extreme Performance

Achieving ideal warm execution requires cautious thought of a few plan parameters. Stick stature, breadth, dividing, and course of action all impact wind current behavior and warm exchange effectiveness. Engineers frequently utilize warm reenactments and testing to fine-tune these factors based on particular application requirements.

Surface medicines such as anodizing can too improve solidness and erosion resistance without altogether influencing warm conductivity. When combined with legitimate mounting methods and warm interface materials, a well-designed warm sink framework can convey steady execution over long working lifetimes.

Balancing Execution, Fetched, and Reliability

While high-performance cooling is fundamental, taken a toll and manufacturability cannot be overlooked. Pin-based plans offer a solid adjust between warm productivity and generation achievability. They can be adjusted for diverse budgets and execution targets by altering materials, fabricating strategies, and plan complexity.

Reliability is another basic calculate. By keeping up lower and more steady working temperatures, successful warm arrangements diminish warm push on components. This leads to less disappointments, lower upkeep costs, and moved forward by and large framework reliability—key benefits for both producers and conclusion users.

Future Patterns in Warm Management

As hardware proceed to progress, warm administration innovations will too advance. Expanding utilize of simulation-driven plan, progressed materials, and crossover cooling frameworks will advance progress execution in high-density situations. Pin-based structures are likely to stay a center arrangement due to their demonstrated viability, versatility, and compatibility with rising fabricating techniques.

In the future, integration with fluid cooling, warm channels, or vapor chambers may improve their capabilities indeed assist. In any case, the crucial standards of maximizing surface zone, advancing productive wind current, and guaranteeing uniform temperature dispersion will stay central to compelling warm design.

Conclusion

Managing warm in high-density electronic frameworks is one of the most critical challenges confronting advanced building. Arrangements that combine compact shape variables with tall warm productivity are basic to meet execution and unwavering quality requests. By leveraging cleverly plan, optimized wind stream, and demonstrated fabricating strategies, pin-based cooling arrangements give a solid reply to these challenges. With appropriate customization and integration, they proceed to play a imperative part in guaranteeing steady, long-lasting execution over a wide extend of requesting applications.