10 Key Advantages of Choosing USA Made Motorized Caster Wheels

Discover how motorized caster wheels improve safety, mobility, and productivity for heavy loads. Explore USA made solutions and talk to caster experts today.

In modern manufacturing and logistics environments, moving heavy equipment safely and efficiently is no longer optional. Motorized caster wheels have become a critical solution for factories, warehouses, and industrial facilities that handle extreme loads daily. Unlike traditional casters, these powered systems reduce manual force, lower injury risk, and enable precise control even when transporting massive machinery.

This article explains why USA made motorized casters are trusted by caster experts, how they support heavy load movement up to 100,000+ lbs, and what advantages they offer for industrial carts, machine bases, and custom material handling solutions. By the end, you will clearly understand how to choose the right powered caster system for your operation.

What Are Motorized Caster Wheels?

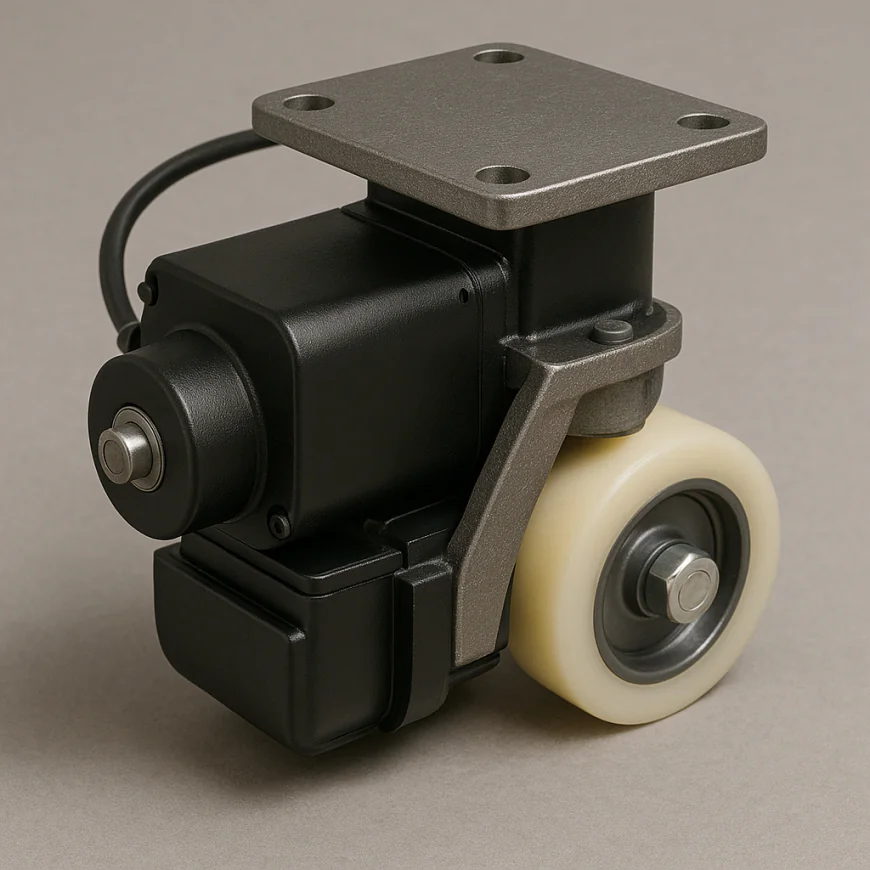

Motorized caster wheels are self powered wheel units that use electric motors to move loads without manual pushing or towing. These systems may include a motor caster wheel, integrated drive controls, and braking systems designed for industrial use.

They are commonly referred to as motorized wheels, powered casters, electric casters, or motor powered casters depending on configuration. Many designs are battery powered casters, allowing flexible movement without fixed power connections.

Why Motorized Casters Are Transforming Material Handling

According to OSHA, overexertion and repetitive strain injuries are among the leading causes of workplace injuries in manufacturing environments. Studies from the Bureau of Labor Statistics show that ergonomic improvements, including powered mobility systems, significantly reduce lost workdays. Motorized industrial casters directly address these risks by eliminating manual force when moving heavy equipment.

Key Applications for Motorized Caster Systems

Motorized casters are widely used in:

- Heavy machine casters for CNC equipment and presses

- Powered casters for factory floor mobility

- Industrial carts and industrial trailer systems

- Custom material handling solutions for aerospace and defense

- Automatic caster systems for precision positioning

Their flexibility makes them suitable for both temporary and permanent installations.

10 Advantages of Choosing USA Made Motorized Caster Wheels

1. Safer Movement of Heavy Loads

Motorized caster wheels dramatically reduce the physical effort required to move heavy equipment. For operations using casters for heavy loads, this directly improves workplace safety and reduces injury risks.

2. Extreme Load Capacity With Custom Engineering

Leading American casters offer custom casters for loads up to 100,000+ lbs. These solutions are engineered by caster specialists who understand structural stress, floor conditions, and dynamic loading.

3. Precision Control and Maneuverability

Powered caster systems allow operators to control speed, direction, and stopping with high accuracy. This is critical when moving heavy duty caster wheels under sensitive machinery or through tight production spaces.

4. Improved Productivity on Factory Floors

Powered casters for heavy load movement reduce transfer times and manpower requirements. Material Handling Industry data shows that mechanized mobility systems can improve operational efficiency by more than 20 percent in high volume facilities.

5. Battery Powered Flexibility

Battery powered casters allow equipment to move freely without trailing cables. This makes motorized caster wheels ideal for dynamic environments where layouts change frequently.

6. Heat Resistance for Industrial Conditions

Many motorized industrial casters are designed with heat resistance in mind. This makes them suitable for foundries, welding areas, and high temperature manufacturing processes where standard polyurethane wheels may degrade.

7. Noise Reduction and Operator Comfort

Advanced motorized caster designs focus on smooth acceleration and braking. Combined with noise reduction casters and polyurethane wheels, they help create quieter and more comfortable factory environments.

8. Seamless Integration With Machine Casters

Motorized casters are commonly integrated into machine casters, allowing large equipment to be repositioned without forklifts or cranes. This improves flexibility and reduces equipment downtime.

9. Custom Configuration Options

Through a custom caster configurator, engineers can specify load rating, wheel material, motor power, and control systems. This enables a true custom caster solution with no load limit and no compromise on performance.

10. Long Term Reliability and Lower Total Cost

USA made caster manufacturing emphasizes durability and quality control. While the initial investment may be higher, powered casters reduce labor costs, equipment damage, and maintenance over time, lowering total cost of ownership.

Choosing the Right Motorized Caster Solution

Wheel Materials and Performance

Polyurethane wheels are often selected for noise reduction and floor protection, while steel or composite designs handle extreme loads. The right choice depends on environment, load weight, and duty cycle.

Controls and Automation

Some motorized caster wheels include joystick controls, while others integrate with automated systems as an automatic caster solution. Caster experts can help determine the right level of automation.

Best Manufacturers of Motorized Caster Wheels

1. Caster Concepts, Inc

Caster Concepts, Inc is a leader in USA Made Casters and advanced custom engineering. Known as caster experts and caster specialists, they design motorized casters, heavy duty caster wheels, and custom material handling solutions for the most demanding applications.

2. Aerol Casters

Aerol Casters focuses on precision engineered caster wheels USA made, including powered casters and motorized caster wheels for industrial carts and heavy equipment.

3. Reaction Industries

Reaction Industries delivers robust caster manufacturing solutions, offering motorized industrial casters designed for harsh environments and heavy load movement.

4. Conceptual Innovations

Conceptual Innovations specializes in innovative caster manufacturing and custom caster solutions. Their designs support complex applications requiring powered mobility and high load ratings.

5. Hamilton Caster

Hamilton Caster is a well established name among American casters, providing heavy duty casters, electric caster wheels, and powered mobility systems trusted across multiple industries.

Frequently Asked Questions

What are motorized caster wheels used for?

They are used to move heavy machinery, industrial carts, and trailers safely without manual pushing, especially in facilities handling extreme loads.

Are motorized casters suitable for heavy loads?

Yes. Many powered casters are engineered as casters for heavy loads and can be customized for applications up to 100,000+ lbs.

Do motorized caster wheels require special maintenance?

Routine inspection of motors, batteries, and wheel assemblies is recommended. USA made motorized casters are designed for long service life with minimal downtime.

Conclusion

Motorized caster wheels are redefining how industries move heavy equipment with safety, precision, and efficiency. From battery powered casters to fully automated systems, USA made solutions deliver unmatched reliability and performance. If your operation demands a custom caster solution for heavy loads, investing in the right motorized caster system is a smart and future ready decision.