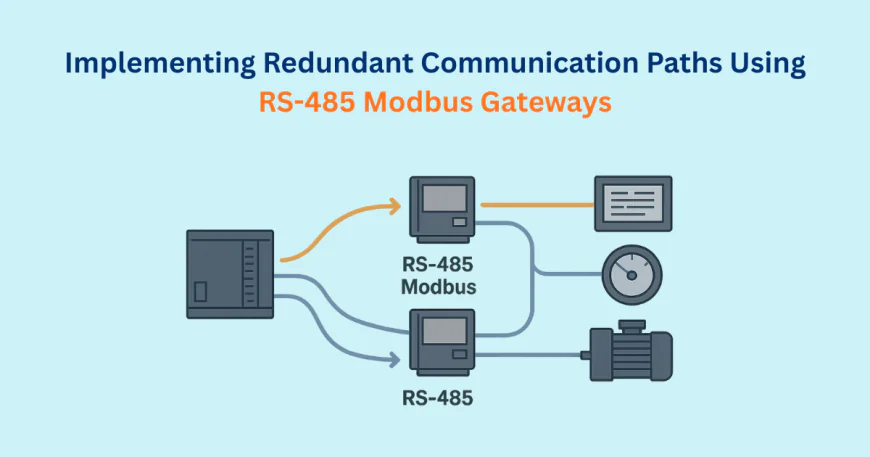

Implementing Redundant Communication Paths Using RS-485 Modbus Gateways

RS485 Modbus Redundant Communication ensures reliable data flow by using dual paths to prevent downtime and enhance industrial network stability.

Industries continue to increase their reliance on connected systems for automation, control, and monitoring. Data collected by Statista shows that the industrial communication market reached USD 20.2 billion in 2023. The number may reach USD 28 billion by 2028 as factories adopt more connected equipment. In another report, Control Engineering found that over 60% of industrial plants still depend on RS-485 networks for field communication because of their stability and long-distance capability.

These numbers highlight the need for strong communication paths in industrial networks. Failures in communication can stop production, increase downtime, and cause safety risks. Redundant communication ensures that devices stay connected even when one path fails. RS-485 Modbus Gateways and RS-485 IoT Gateways support this setup by offering reliable communication across large networks.

This article explains how redundancy works using RS-485 technology. It covers technical concepts, design methods, gateway features, and real project examples.

Role of RS-485 in Industrial Communication

Why RS-485 Is Still Important

RS-485 remains a preferred communication method in factories and remote installations. Reasons include:

-

Long cable distance, often up to 1200 meters

-

Strong noise resistance

-

Support for multi-drop networks

-

Low latency

-

Stable differential signalling

These features suit plants with motors, inverters, and heavy machinery. Noise immunity keeps the communication link safe even in harsh electrical environments.

Why Modbus Fits RS-485

Modbus RTU works well on RS-485 lines because it uses simple frames and predictable timing. Devices can share data without a complex setup. It remains one of the most used industrial protocols.

Why Redundant Communication Paths Matter

Industrial communication must stay active even when cables, nodes, or interfaces fail. A single failure can stop the entire line.

Common Failure Points

-

Cable cuts due to wear

-

Port damage

-

Electromagnetic interference

-

System overload

-

Device failure on the bus

-

Power issues

Redundancy ensures continuous data flow during these failures.

Benefits of Redundant Paths

-

Higher system uptime

-

Better safety

-

Accurate real-time data

-

Predictable behaviour during failures

-

Reduced maintenance cost

-

Reliable performance in remote sites

Industries such as manufacturing, oil and gas, utilities, and transport rely on redundancy to avoid disruptions.

Understanding RS-485 Modbus Gateways

What the Gateway Does

An RS-485 Modbus Gateway connects Modbus RTU devices to other networks like Ethernet, serial buses, or IoT systems. It routes data between these networks and manages traffic.

Key tasks include:

-

Protocol translation

-

Bus management

-

Device mapping

-

Data filtering

-

Error handling

-

Communication recovery

Gateways add intelligent features to traditional RS-485 systems.

How RS-485 IoT Gateways Improve Connectivity

An RS-485 IoT Gateway adds cloud and IP connectivity while keeping RS-485 at the field level. This gives industrial systems a stable link to cloud dashboards and remote monitoring tools.

Common IoT Features

-

MQTT support

-

HTTPS or REST APIs

-

Secure cloud tunnels

-

Remote firmware updates

-

Edge processing

These features help industries collect and manage data from remote sites.

Building Redundant Paths Using RS-485 Gateways

Redundancy uses alternate routes to maintain communication when the main route fails. A gateway handles the failover logic.

1. Dual-Port RS-485 Gateways

These gateways include two RS-485 ports. Each port connects to a separate bus.

How It Works

-

Both ports stay active.

-

The gateway polls both buses

-

If one bus fails, the gateway switches communication.

-

Devices keep sending data through the working path.

This method protects the network from bus-level failures.

Suitable For

-

Large plants

-

Multi-building sites

-

Redundant monitoring loops

2. Ring Topology with Gateways

A ring provides two communication directions. If one path breaks, data travels through the opposite side.

Benefits

-

Fast failure detection

-

Short rerouting time

-

Support for large node counts

Gateways sense the break and redirect packets around the ring.

3. Parallel Network Architecture

Two independent RS-485 networks run side by side. Each carries the same device data.

Operation

-

Primary network handles normal traffic

-

The Secondary network stays as a backup.

-

Gateway monitors both networks.

-

Failover happens when the primary path fails.

This method protects against cable damage and electrical noise.

4. Ethernet-Backed Redundancy with RS-485 Gateways

Many RS-485 Modbus Gateways include Ethernet. This adds an extra layer of redundancy.

Path Options

-

RS-485 → Gateway → Ethernet

-

RS-485 → Gateway → Wi-Fi or LTE

-

Multiple gateways sharing the same device map

If the RS-485 line fails, the gateway continues communication through the IP network.

5. Cellular Backup Through IoT Gateways

Some RS-485 IoT Gateways include 4G or LTE modules. Cellular links serve as backup routes when wired paths fail.

Advantages

-

Works in remote sites

-

Offers long-range access

-

Reduces downtime during physical failures

This method suits utilities, farms, and moving equipment.

Technical Features Required for Redundant RS-485 Designs

1. Auto-Failover Logic

Gateways must detect failure and switch paths with near-zero delay.

2. Dual-Watchdog Timers

They keep gateway CPUs responsive during heavy load.

3. Isolation

Optical isolation protects against ground loops and voltage spikes.

4. High Noise Immunity

RS-485 already offers this, but gateways improve it with filters and shielding.

5. Real-Time Alerts

The system should send alerts when failures occur.

6. Latency Control

Redundancy must not increase the delay between devices and gateways.

7. Flexible Starting Points

Gateways should support many wiring structures: ring, bus, or hybrid.

Planning Redundant RS-485 Networks

A well-designed redundant network reduces failures and increases long-term performance.

1. Identify Critical Nodes

Start with nodes that must never fail:

-

Safety sensors

-

High-pressure monitoring

-

Temperature alarms

-

SCADA nodes

-

Condition monitoring devices

These nodes should receive dual communication paths.

2. Map Failure Points

Engineers must review:

-

Cable routes

-

Power sources

-

Node spacing

-

Electromagnetic noise sources

Weak points help decide where redundancy is needed.

3. Choose Gateway Type

Different gateways serve different needs:

-

Dual-port RS-485 Modbus Gateways

-

Ethernet-enabled RS-485 IoT Gateways

-

Cellular backup gateways

-

Multi-bus Modbus routing gateways

Selection depends on device count, latency, and network layout.

4. Test Recovery Behaviour

Testing includes:

-

Cable cut simulation

-

Node failure

-

Power loss

-

High noise exposure

-

Load testing

Recovery time must stay consistent during all events.

Real-World Application Examples

1. Power Distribution Grids

Grid monitoring requires continuous data. RS-485 Gateways support transformers, meters, and breakers.

Redundancy protects the grid from outages caused by line faults.

2. Oil and Gas Pipelines

Pipelines run across long and remote routes. Cellular backup through RS-485 IoT Gateways improves reliability.

Redundant paths reduce the risk of data loss during storms or cable breaks.

3. Factory Automation

Factories use Modbus RTU for motors, sensors, and drives. Dual-port redundancy protects production lines from downtime.

4. Water Treatment Systems

Pumps, chemical feeders, and sensors must communicate without interruption. Gateways forward data through alternate paths when failures occur.

5. Transport Infrastructure

Tunnels, rail stations, and highways use RS-485 sensors. LTE-backed redundancy increases uptime.

Performance Analysis of Redundant RS-485 Paths

|

Feature |

Single RS-485 Path |

Redundant RS-485 Path |

|

Uptime |

Medium |

Very High |

|

Latency |

Low |

Low |

|

Failure Impact |

High |

Low |

|

Maintenance Demand |

High |

Medium |

|

Noise Resistance |

Good |

Very Good |

|

Scalability |

Medium |

High |

Redundant paths often reduce total downtime by over 70% in field deployments, based on industrial case studies.

Security Considerations

1. Port Protection

Keep gateway ports isolated and shielded.

2. Role-Based Access

Grant access only to authorised engineers.

3. Encrypted IP Routes

IoT gateways should use TLS or VPN layers.

4. Firmware Control

Always update gateways with signed firmware.

Why RS-485 Gateways Support Long-Term Reliability

Even as Ethernet and wireless grow, RS-485 networks remain important. Many factories depend on legacy devices that still run well. Replacing them can be costly. Gateways add modern features without replacing existing equipment.

Key long-term reasons include:

-

Proven long-distance communication

-

Strong noise immunity

-

Low-cost wiring

-

High compatibility

-

Predictable timing

Redundant paths increase system stability and support industrial growth.

Conclusion

Redundant communication is essential for industrial systems that rely on continuous data. RS-485 Modbus Gateways and RS-485 IoT Gateways offer strong support for building these redundant paths. They provide failover, multi-bus support, cloud access, and stable recovery features.

Industries that depend on real-time operations—manufacturing, utilities, transport, and energy—gain higher uptime and reduced risk with redundant RS-485 paths. When paired with careful planning and testing, these gateways create stable and future-ready communication networks.