How CNC Machining is Revolutionizing Modern Manufacturing Industries

CNC machining, or Computer Numerical Control machining, has become a cornerstone in the evolution of modern manufacturing industries. This technology utilizes pre-programmed software to control complex machinery and tools, enabling manufacturers to produce highly precise components with minimal human intervention. Since its inception in the mid-20th century, CNC machining has undergone significant advancements, transitioning from rudimentary punch card systems to sophisticated software-driven operations that integrate seamlessly with Industry 4.0 technologies.

The adoption of CNC machining has been pivotal in addressing the increasing demand for high-quality, customized, and efficient production processes. From automotive to aerospace, industries worldwide have embraced CNC machining to streamline operations, reduce production time, and maintain consistent quality. Its transformative impact lies not only in its ability to produce intricate parts but also in its capacity to adapt to the ever-changing needs of modern manufacturing.

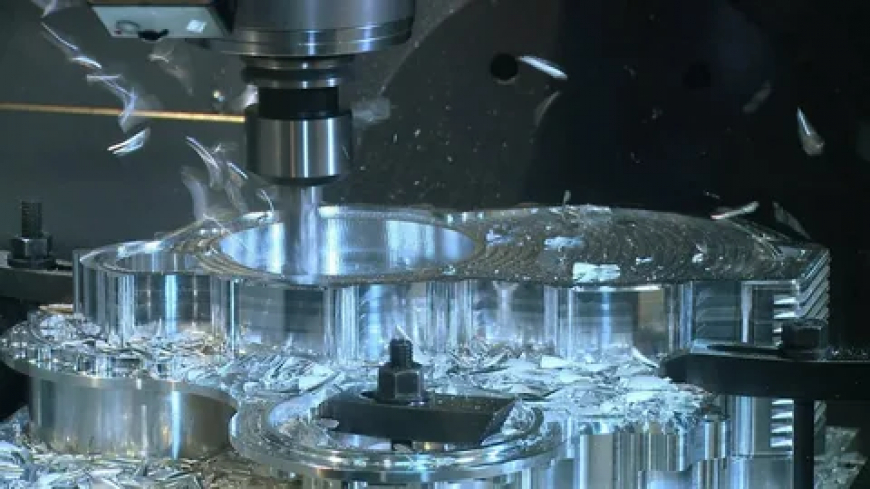

Precision and Efficiency: The Hallmarks of CNC Machining

One of the most significant advantages of CNC machining is its unparalleled precision. Unlike traditional manufacturing methods, which often rely on manual adjustments, CNC machining ensures consistent accuracy through its computer-controlled processes. This precision is crucial for industries like aerospace and medical device manufacturing, where even minor deviations can lead to catastrophic failures or compromised product integrity.

Efficiency is another hallmark of CNC machining. By automating repetitive tasks, CNC machines significantly reduce production times while minimizing errors. Furthermore, the ability to program machines for multi-axis movements allows for the creation of complex geometries in a single setup, eliminating the need for multiple processes. This combination of precision and efficiency has redefined production standards, enabling manufacturers to meet tight deadlines and maintain competitive pricing without sacrificing quality.

The Role of CNC Machining in Customization and Innovation

Modern consumers demand personalized products, and CNC machining has risen to the challenge by facilitating mass customization. With its programmable nature, CNC machining can quickly switch between different designs without extensive retooling. This flexibility is invaluable for industries such as consumer electronics, where product lifecycles are short, and customization is a key differentiator.

In addition to customization, CNC machining is a driving force behind innovation. By enabling the production of prototypes with intricate designs and tight tolerances, CNC machining accelerates the development of new products. This capability supports industries like automotive and aerospace in pushing the boundaries of design and functionality, fostering a culture of innovation and continuous improvement.

Sustainability and Cost-Effectiveness in CNC Machining

Sustainability is becoming a critical concern for manufacturers, and CNC machining contributes positively to this goal. The precision of CNC machining reduces material waste by ensuring optimal usage of raw materials. Additionally, modern CNC machines often incorporate energy-efficient technologies and advanced cooling systems, further minimizing their environmental impact.

From a cost perspective, CNC machining offers substantial savings in the long run. While the initial investment in CNC equipment and software can be high, the reduced labor costs, minimized waste, and faster production times result in significant cost efficiencies. Moreover, the durability and reliability of CNC machines mean fewer disruptions and maintenance expenses, ensuring consistent production outputs over extended periods.

The Future of CNC Machining in Modern Manufacturing

As technology continues to advance, the future of CNC machining looks promising. The integration of artificial intelligence (AI) and machine learning is set to enhance the capabilities of CNC machines, enabling predictive maintenance, real-time quality control, and improved programming efficiency. Additionally, advancements in materials science are expanding the range of materials that can be processed through CNC machining, from traditional metals to advanced composites and ceramics.

The advent of additive manufacturing, or 3D printing, also complements CNC machining by offering new possibilities for hybrid manufacturing approaches. By combining the strengths of both technologies, manufacturers can achieve unprecedented levels of efficiency, precision, and design freedom. In this rapidly evolving landscape, CNC machining remains a foundational pillar, driving innovation and ensuring the continued growth of modern manufacturing industries.