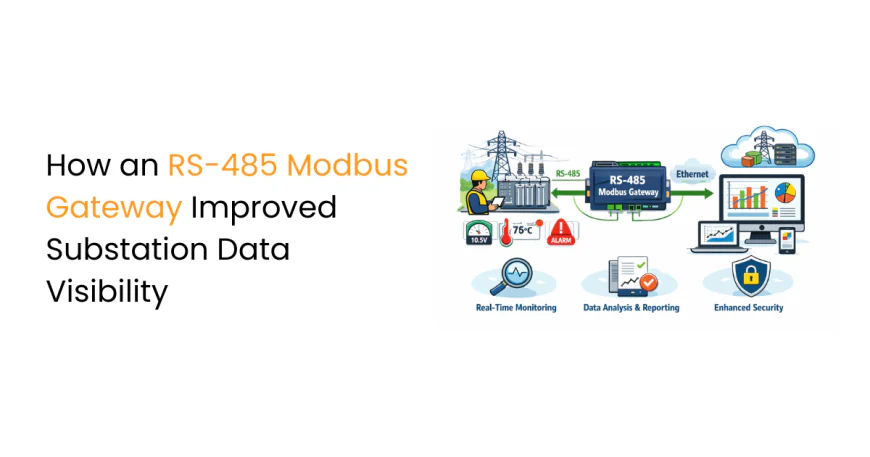

How an RS-485 Modbus Gateway Improved Substation Data Visibility

RS485 Gateway improves substation data visibility by enabling reliable Modbus communication, real-time monitoring, and better operational insights.

Modern electrical substations are critical nodes in the power grid, handling voltage transformation, power distribution, and protection. Effective operation depends on accurate, real-time data from numerous devices, including circuit breakers, relays, meters, and transformers. However, many substations still rely on traditional SCADA systems and manual data collection, which limits visibility, slows response times, and increases operational costs.

RS-485 Modbus gateways have emerged as an essential solution, bridging legacy substation equipment with modern monitoring platforms, including SCADA, IoT, and cloud systems. This article explains how RS-485 Modbus and RS-485 IoT gateways improve substation data visibility, the technical mechanisms behind them, deployment considerations, and real-world examples.

Understanding the Challenges in Substation Data Monitoring

Substations handle critical electrical infrastructure, but their operational efficiency depends on data from devices such as:

-

Circuit breakers – monitor load currents and fault conditions.

-

Transformers – track voltage, current, and temperature.

-

Relays – protect the system and trigger alarms during faults.

-

Energy meters – measure energy consumption and quality.

Traditional monitoring systems face the following challenges:

-

Limited Real-Time Visibility – Many RS-485 Modbus RTU devices are polled at intervals, often every 30 seconds to 5 minutes. This delay can prevent timely detection of faults.

-

Complex Integration – Legacy devices often cannot directly communicate with modern Ethernet-based SCADA or cloud systems.

-

Data Loss or Inaccuracy – Manual readings or isolated systems can cause errors.

-

High Maintenance Costs – Managing and maintaining separate networks for each device increases operational overhead.

An RS-485 Modbus gateway addresses these challenges by collecting data from multiple devices, converting protocols, and enabling remote monitoring.

What is an RS-485 Modbus Gateway?

An RS-485 Modbus gateway is a device that connects RS-485 Modbus devices to modern networks such as Ethernet, Wi-Fi, or IoT systems. It converts Modbus RTU or Modbus ASCII protocols into TCP/IP, MQTT, or other modern protocols.

Technical Features

-

Protocol Conversion: Translates legacy Modbus signals to Ethernet or IoT protocols.

-

Multi-Device Support: Can manage communication with 16–128 RS-485 devices, depending on the gateway model.

-

Low Latency Data Transfer: Supports real-time data collection with delays as low as 1–2 seconds.

-

Security Measures: Includes encryption, user authentication, and firewall support to protect sensitive substation data.

-

Diagnostics: Many gateways provide status reporting for each connected device, enabling fast troubleshooting.

In practice, this means a single gateway can consolidate data from multiple relays, meters, and transformers and transmit it to a SCADA or IoT platform for centralized monitoring.

RS-485 IoT Gateway and Its Benefits

An RS-485 IoT gateway extends the capabilities of a traditional Modbus gateway by enabling cloud connectivity and advanced analytics. It allows substations to participate in smart grid ecosystems and predictive maintenance programs.

Key functionalities include:

-

Cloud Connectivity: Supports MQTT, CoAP, and HTTP protocols to send real-time data to cloud servers.

-

Data Analytics: Enables trend analysis, predictive maintenance, and anomaly detection.

-

Remote Device Management: Firmware updates, device reconfiguration, and monitoring from a central control location.

-

Scalability: Easy addition of new devices without complex rewiring or infrastructure upgrades.

For example, a utility company can connect multiple substations to a single cloud platform, enabling centralized control and operational analytics across a city-wide grid.

How RS-485 Gateways Improve Substation Data Visibility

1. Centralized Data Collection

RS-485 Modbus gateways aggregate data from multiple devices into one communication channel. In large substations, this can include:

-

40–50 meters

-

10–20 protection relays

-

5–10 transformers

Previously, operators had to poll each device manually, often resulting in data collection intervals of 15–30 minutes. With gateways:

-

All devices can be polled simultaneously.

-

Data updates can occur every 1–2 seconds.

-

SCADA or IoT dashboards receive real-time values for voltage, current, frequency, and other parameters.

2. Real-Time Monitoring

Real-time monitoring allows operators to respond immediately to abnormal conditions, such as:

-

Transformer overloading

-

Sudden voltage drops

-

Circuit breaker trips

Example: In one regional substation, implementing RS-485 IoT gateways reduced the average fault detection time from 20 minutes to 5 seconds.

A 2021 IEEE study shows that real-time monitoring systems reduce substation downtime by 30–50%, significantly improving grid reliability.

3. Protocol Translation and System Integration

Many substations rely on legacy devices that only support RS-485 Modbus RTU. Modern SCADA, IoT, or cloud systems require Ethernet or MQTT protocols. Gateways serve as translators:

-

RS-485 Modbus RTU → TCP/IP for SCADA integration

-

RS-485 Modbus → MQTT/CoAP for IoT/cloud integration

This allows utilities to:

-

Extend the lifespan of legacy devices

-

Avoid costly hardware replacements

-

Build hybrid systems that combine old and new technologies

4. Improved Data Accuracy and Reliability

RS-485 Modbus gateways ensure high-quality, error-free data:

-

Redundant communication paths reduce the risk of lost packets.

-

Built-in error checking corrects Modbus transmission errors.

-

Timestamp synchronization ensures data from different devices aligns accurately.

Accurate data supports better operational decisions, reduces downtime, and improves predictive maintenance models.

Practical Case Study: Substation Upgrade with RS-485 IoT Gateways

A utility company in India upgraded three 220 kV substations using RS-485 IoT gateways.

Before Upgrade:

-

Devices polled manually every 30 minutes

-

Fault detection delays of 20–30 minutes

-

Reactive maintenance with frequent outages

After Upgrade:

-

All 45 devices in each substation connected via RS-485 gateways

-

Real-time monitoring with 1–2 second updates

-

Automated alerts for faults, overloads, and abnormal voltage fluctuations

Results:

-

Downtime reduced by 40%

-

Maintenance efficiency improved by 25%

-

Operational cost savings of ~15% annually

This demonstrates the tangible benefits of integrating gateways in substations.

Technical Considerations for Deployment

Deploying RS-485 Modbus or IoT gateways requires careful planning to maximize benefits.

1. Device Compatibility

-

Ensure the gateway supports Modbus RTU or ASCII devices in use.

-

Verify the maximum number of devices per port and total load on the gateway.

2. Network Infrastructure

-

Ensure reliable wired (Ethernet) or wireless (Wi-Fi, cellular) connectivity.

-

Use VLANs or dedicated substation networks for security.

3. Protocol Selection

-

TCP/IP is optimal for SCADA integration.

-

MQTT is preferred for cloud-based monitoring and IoT applications.

4. Environmental Conditions

-

Gateways must withstand high temperatures (–20°C to 70°C) and humidity (0–95%).

-

Industrial-grade enclosures provide protection against dust and electromagnetic interference.

5. Cybersecurity

-

Enable encryption (SSL/TLS) for data transmission.

-

Use strong authentication for remote access.

-

Segment the gateway network from public networks to prevent unauthorized access.

6. Maintenance and Training

-

Operators need training for monitoring dashboards, device configuration, and troubleshooting.

-

Regular firmware updates keep gateways secure and stable.

Advantages Over Traditional Systems

|

Feature |

Traditional RS-485 System |

RS-485 Gateway System |

|

Data Collection |

Manual or slow polling |

Real-time aggregation from multiple devices |

|

Integration |

Limited to legacy SCADA |

Integrates with SCADA, cloud, and IoT |

|

Maintenance |

Reactive |

Predictive with alerts |

|

Scalability |

Difficult, complex wiring |

Simple, modular addition of devices |

|

Data Accuracy |

Prone to errors |

High reliability with error correction |

The benefits clearly justify the investment in RS-485 gateways for utilities aiming to modernize operations.

Statistical Insights and Industry Data

-

Substations with RS-485 IoT gateways report 30–50% fewer downtime incidents (IEEE 2021).

-

Gateways reduce data latency to 1–2 seconds, compared to 15–30 seconds in manual polling systems.

-

Integration with IoT platforms improves energy efficiency by up to 20% through better load monitoring.

-

Predictive maintenance using gateway-collected data reduces transformer failures by up to 25% annually.

These numbers highlight that RS-485 gateways provide measurable operational, financial, and safety improvements.

Challenges and Mitigation

1. Legacy Device Limitations

Older devices may have slow communication speeds or limited registers.

Mitigation: Use gateways with configurable polling intervals and multi-master support.

2. Network Congestion

High traffic can reduce performance.

Mitigation: Implement segmented networks, prioritization, and data compression features.

3. Cybersecurity Risks

Connecting substations to the Internet increases attack risks.

Mitigation: Use VPNs, firewalls, encryption, and regular security audits.

4. Operator Training

Operators may be unfamiliar with cloud-based monitoring.

Mitigation: Provide training sessions, tutorials, and remote support.

Future Trends

RS-485 IoT gateways are evolving to provide advanced features:

-

Edge Computing: Local processing reduces latency and network load.

-

AI-Based Analytics: Predicts faults before they occur using historical data.

-

Wireless RS-485 Integration: Reduces cabling costs in large substations.

-

Smart Grid Compatibility: Enables better load balancing, demand response, and energy optimization.

These trends indicate that gateways will remain a core technology in substation modernization and smart grid development.

Conclusion

RS-485 Modbus and IoT gateways significantly improve substation data visibility. They provide centralized monitoring, real-time alerts, protocol translation, and predictive maintenance capabilities. Utilities that adopt these gateways experience:

-

Reduced downtime

-

Improved data accuracy

-

Cost savings in operations and maintenance

-

Easier integration with modern SCADA, IoT, and cloud platforms

As substations continue to modernize, RS-485 gateways offer a cost-effective solution to extend legacy infrastructure, improve operational reliability, and enable smarter energy management. By implementing these gateways, utilities can build safer, more efficient, and more resilient electrical networks.