Why Heavy Duty Drive Casters Are Ideal for Material Handling

Discover why heavy duty drive casters are the best choice for industrial material handling. Explore powered options for efficient, high-capacity movement.

In today’s fast-paced industrial environments, heavy duty drive casters are no longer a luxury they’re a necessity. Whether you're moving oversized machinery, transporting heavy loads in warehouses, or streamlining production processes, powered mobility solutions like drive casters play a vital role in reducing manual labor and increasing operational efficiency.

But what exactly makes heavy duty drive casters the ideal solution for material handling? This article explores the key features, benefits, and applications of these industrial workhorses, comparing them to other powered and motorized solutions.

What Are Heavy Duty Drive Casters?

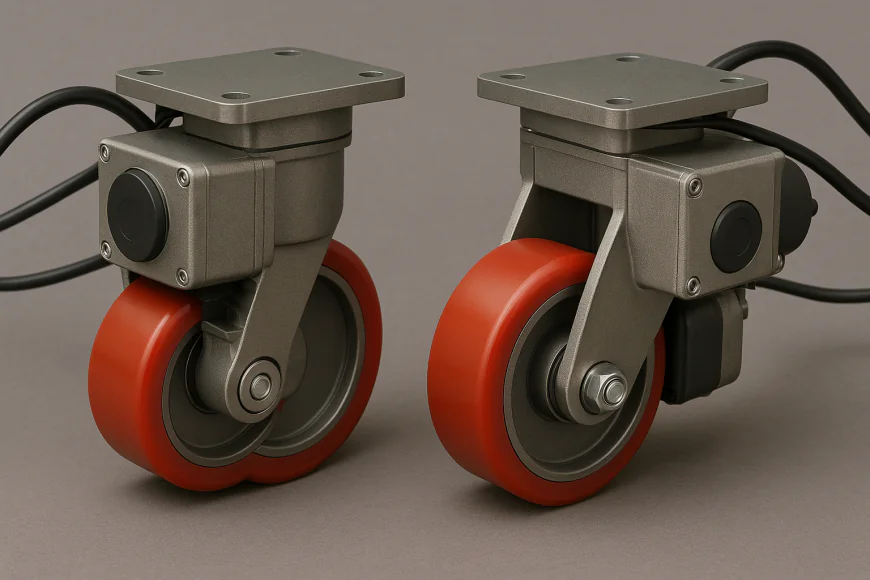

Heavy duty drive casters are motorized wheel assemblies that integrate drive systems directly into the caster. Unlike traditional fixed or swivel casters that rely solely on manual force, drive casters provide powered mobility, making it easier to move large or heavy loads with minimal effort.

These casters combine the structural strength of machine casters with advanced motorized caster wheels, enabling smooth, controlled transport in demanding environments.

Benefits of Heavy Duty Drive Casters in Material Handling

1. Reduced Labor Costs and Physical Strain

With motorized caster wheels or powered casters, employees can move heavy loads without pushing or pulling, reducing injuries and labor costs.

2. Increased Efficiency and Productivity

Integrated drive systems ensure faster, controlled movement. Tasks that once required multiple workers or forklifts can now be completed by one operator using motorized wheels for carts or drive units.

3. Customizable Solutions for Specialized Needs

Custom drive casters can be tailored to specific load capacities, floor conditions, and operational needs. Whether you're dealing with sensitive equipment or rugged outdoor surfaces, there’s a solution available.

4. Heavy Load Capacity

Built for industrial environments, heavy duty drive casters handle loads ranging from hundreds to thousands of pounds, making them ideal for heavy manufacturing, aerospace, and automotive applications.

Key Features of Heavy Duty Drive Casters

- Integrated Drive System: Enables self-powered movement, reducing the need for manual handling.

- High Load Capacity: Supports and transports heavy machinery and equipment efficiently.

- Precision Control: Allows smooth acceleration, controlled stops, and accurate directional changes for safe operation.

- Versatility: Available in various configurations, including electric caster wheels, powered casters, and motorized drive systems to suit different industrial applications.

- Durability: Constructed from rugged, industrial-grade materials to ensure long-term reliability in demanding environments.

Applications of Motorized Casters and Powered Casters

- Warehouse Automation: Ideal for AGVs (Automated Guided Vehicles) and robotic transport systems.

- Manufacturing Plants: Simplify movement of heavy tools, molds, and equipment.

- Aerospace & Defense: Move delicate, high-value components with precision.

- Material Handling Carts: Enhance safety and efficiency with motorized wheels for carts.

- Automotive Production: Power large-scale assembly line transport systems.

Comparing Heavy Duty Drive Casters to Other Solutions

-

Heavy Duty Drive Casters

-

Advantages: Self-powered, scalable, customizable

-

Limitations: Higher initial investment

-

-

Traditional Casters

-

Advantages: Simple, low-cost

-

Limitations: Requires manual labor, higher injury risk

-

-

Forklifts / AGVs

-

Advantages: High power, automation

-

Limitations: Expensive, complex setup

-

-

Powered Casters

-

Advantages: Adds mobility to existing carts or platforms

-

Limitations: Requires power source integration

-

Choosing the Right Industrial Drive Casters

When selecting industrial drive casters or motorized caster wheels, consider:

- Load weight and frequency of movement

- Floor conditions and environment (wet, oily, uneven)

- Power requirements (battery, wired)

- Safety and ergonomic benefits

- Required speed and maneuverability

Partner with a reputable manufacturer for custom drive casters tailored to your facility’s needs.

Future Trends in Powered Material Handling Solutions

With Industry 4.0 adoption, demand for powered casters and motorized caster solutions will continue to rise. Automation, wireless control, and smart sensors are being integrated to create responsive, efficient material handling systems.

According to Grand View Research, the global material handling equipment market is expected to reach USD 246.58 billion by 2028, driven by increased automation and ergonomic solutions1.

FAQs About Heavy Duty Drive Casters

What’s the difference between drive casters and powered casters?

Drive casters integrate the motor directly into the caster assembly, whereas powered casters can refer more broadly to any caster system that uses external or internal power to assist movement.

Are motorized wheels for carts suitable for outdoor use?

Yes, with proper customization. Motorized wheels for carts can be equipped with weather-resistant materials and IP-rated motors for outdoor or harsh environments.

Can I get custom drive casters for specialized equipment?

Absolutely. Many manufacturers offer custom drive casters designed to match unique load requirements, floor conditions, and operational goals.

Conclusion

Heavy duty drive casters are transforming the material handling landscape by combining power, precision, and durability into a single solution. From reducing manual labor to enhancing safety and efficiency, these motorized caster wheels deliver measurable benefits across industries.

Ready to upgrade your operations? Explore heavy duty drive casters designed for your application and experience the future of material handling today.