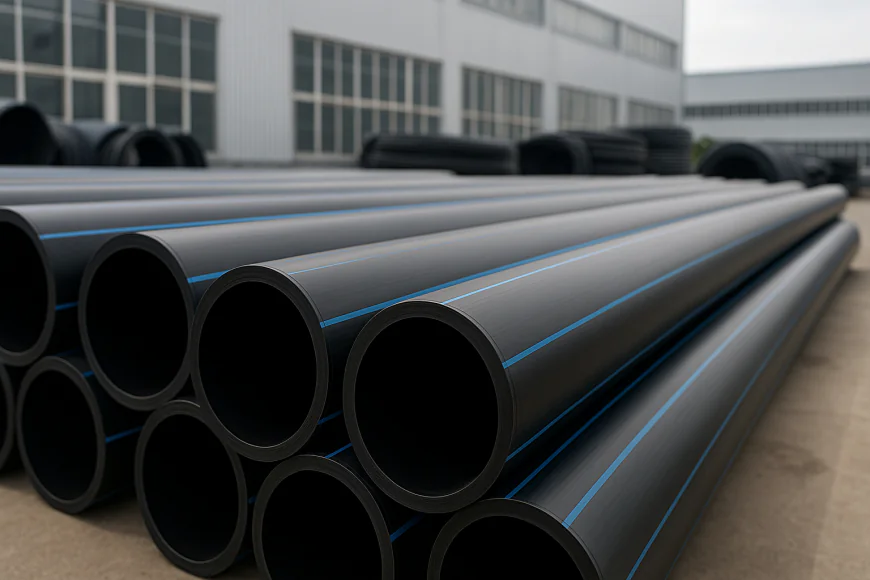

HDPE Pipes Installation: Enabling Strong and Efficient Water & Sewage Treatment Networks

Learn how HDPE Pipes Installation ensures leak-proof, long-lasting water and sewage networks through superior strength, corrosion resistance, and sustainable performance.

With increasing urbanization and intensifying water stress, treating wastewater more efficiently is now a great necessity. Urban and industrial infrastructures need an efficient and sustainable piping system, which can handle water and sewage.

Medium Density Polyethylene Pipe is the perfect mixture of strength, flexibility and resilience to make it the perfect choice for a modern wastewater network. These pipes are designed to be used for complex flow systems with low leakage and low maintenance costs.

Their ability to integrate with smart monitoring and water recovery technologies makes them a reliable component in the making of today's sustainable wastewater infrastructure.

Understanding Medium Density Polyethylene Pipes

Commonly called MDPE, Medium Density Polyethylene Pipes are pipes made from moderate density thermoplastic material to achieve a balance between flexibility and strength. They are normally utilized for water distribution, wastewater collection, and industrial applications that require a high degree of long-term performance.

Key features include:

-

Corrosion and Chemical Resistance: MDPE pipes resist degradation caused by chemicals, salts, and biological contaminants.

-

Impact Durability: Their flexibility allows them to withstand shocks and ground movement without cracking.

-

Leak-Proof Joints: Fusion jointing ensures a continuous, sealed network that minimizes water loss.

Regardless of challenges such as different types of soils, high water pressure, or extreme temperatures, the Medium Density Polyethylene Pipe is designed to deliver a consistent performance if it is properly installed.

Why MDPE is the Preferred Material for Wastewater Systems

1. Lightweight and Easy to Handle

Unlike steel or concrete pipes, MDPE pipes are light weight, so they are faster to transport and install, which are less labor intensive.

2. Excellent Chemical Compatibility

By having the ability to perform exceptionally well in systems involving sewage or wastewater, they frequently withstand the impact of being subjected to chemicals. Their anti-corrosion property increases the service life of the pipeline.

3. Flexibility and Durability

Their flexible nature helps absorb ground shifts, vibrations, and temperature-induced expansion — a key advantage in preventing pipe failures.

4. Cost-Effectiveness

A Medium Density Polyethylene Pipe (MDPE) has a long working life and needs less maintenance than other pipes, which ensure overall cost saving throughout their healthy working life.

With these advantages, MDPE has become a trusted material for both public utility networks and industrial wastewater systems.

Role in Smart Wastewater Management

Efficient wastewater infrastructure: Smart cities use data-driven and automated infrastructure to optimize the efficiency of wastewater management. MDPE pipe serves an important role in making such advanced systems possible.

-

Integration with Smart Sensors: MDPE networks can be fitted with pressure, flow, and leakage sensors for real-time monitoring.

-

Support for Water Recovery: These pipes help efficiently transport treated wastewater for reuse in irrigation or industrial applications.

-

Low Leakage Rates: Their fusion joints ensure minimal water loss, supporting sustainability goals.

-

Operational Efficiency: Smooth internal surfaces enhance flow, reducing energy consumption in pumping operations.

By adding Medium Density Polyethylene Pipe systems to their municipal and factory raw-water filtration systems, municipalities and industries will be able to increase system efficiency, cut down maintenance downtime and comply with the environment.

Advantages of Using Medium Density Polyethylene Pipes

-

Extended Lifespan: MDPE pipes can last between 50 and 100 years with proper installation.

-

Minimal Maintenance: Their corrosion resistance eliminates frequent repair or replacement needs.

-

Eco-Friendly Material: MDPE is recyclable, helping reduce the environmental footprint of infrastructure projects.

-

Consistent Flow Efficiency: Smooth internal walls reduce friction, ensuring efficient water movement.

-

Adaptability: Suitable for underground, above-ground, and submerged installations.

With proper design, Medium Density Polyethylene Pipe systems provide for increased reliability and a life of service for wastewater networks.

Frequently Asked Questions (FAQ)

Q1: What is a Medium Density Polyethylene Pipe used for?

It is primarily used for water supply, sewage management, and industrial fluid transportation, where long-term durability and leak resistance are required.

Q2: Why is MDPE suitable for wastewater management?

Its flexibility, chemical resistance, and seamless joints make it ideal for handling both treated and untreated wastewater safely.

Q3: How does MDPE differ from HDPE?

MDPE offers greater flexibility and impact resistance, while HDPE provides higher rigidity and strength for high-pressure applications.

Q4: What is the lifespan of a Medium Density Polyethylene Pipe?

Depending on installation and environmental conditions, it typically lasts between 50 and 100 years.

Q5: Can MDPE pipes be used in both above-ground and underground systems?

Yes, their UV resistance and durability make them suitable for both environments.

Conclusion

When it comes to wastewater treatment, the right materials should provide durability, efficiency, and flexibility. The Medium Density Polyethylene Pipe (MDP) meets all these demands making it a preferred option for smart and future-proof wastewater systems.

Its compatibility with systems for monitoring cockpit systems and after dealing with harsh conditions, makes them indispensable for urban and industrial networks. By investing in MDPE technology can provide everyone with leak-proof systems, lower operational costs, and can also have a lower environmental impact.

In the end, the Medium Density Polyethylene Pipe represents a cornerstone of the present cooperation of wastewater management - catching the movement for sustainable infrastructure and resource economy worldwide.