Enhancing Product Quality with Custom CNC Turning Solutions

One of the primary advantages of custom CNC turning is its ability to deliver precision-engineered components.

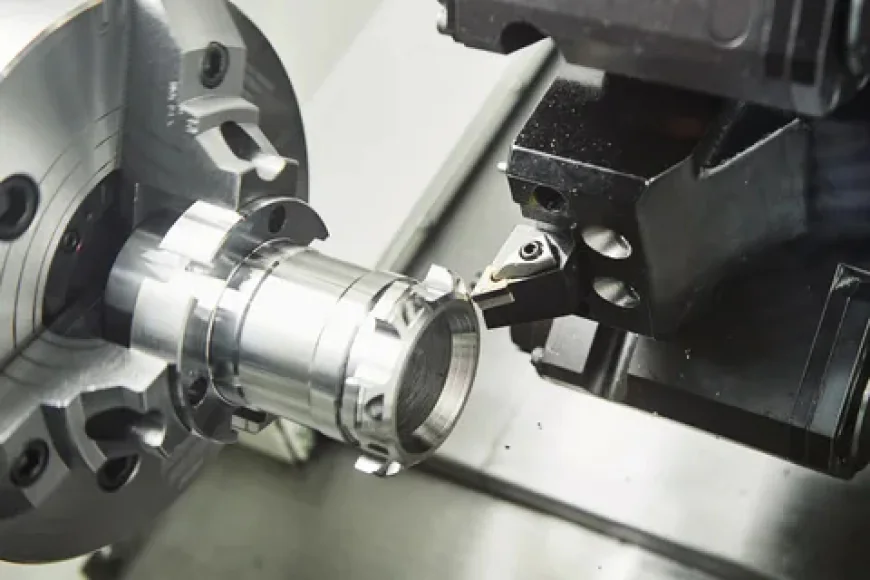

In today’s highly competitive manufacturing landscape, product quality is paramount. Companies are constantly seeking methods to optimize production processes, reduce errors, and deliver high-quality components to their clients. One technology that has emerged as a game-changer in achieving these goals is custom CNC turning. By offering unparalleled precision, efficiency, and repeatability, custom CNC turning enables manufacturers to elevate their product standards while maintaining cost-effectiveness.

Unlike traditional machining methods, custom CNC turning allows for intricate designs and complex geometries to be created with minimal human intervention. This not only reduces the chances of errors but also ensures consistency across production batches. By integrating CNC technology into the production line, manufacturers can achieve superior tolerances and surface finishes, which directly translates into higher product quality and greater customer satisfaction.

Precision Engineering for Superior Products

One of the primary advantages of custom CNC turning is its ability to deliver precision-engineered components. Unlike manual machining, where human error can affect dimensions and tolerances, CNC machines follow programmed instructions with extreme accuracy. This ensures that every component produced meets strict specifications, which is particularly crucial in industries such as aerospace, automotive, and medical devices where even minor deviations can compromise performance and safety.

Moreover, precision in custom CNC turning extends beyond mere dimensions. The technology enables the creation of complex geometries, threads, and contours that would be challenging or impossible to achieve manually. As a result, manufacturers can produce high-quality parts that meet stringent industry standards, improving overall product reliability and customer trust. The combination of precision, repeatability, and versatility positions custom CNC turning as an indispensable tool for companies seeking superior product quality.

Reducing Material Waste and Enhancing Efficiency

Efficiency in manufacturing is directly linked to both cost savings and product quality. Custom CNC turning significantly contributes to operational efficiency by minimizing material waste. CNC machines are programmed to optimize the cutting path and utilize raw materials effectively, reducing excess scrap and lowering production costs. This precise material usage not only benefits the environment but also ensures that high-quality components are consistently produced with minimal errors.

In addition to waste reduction, custom CNC turning improves workflow efficiency. Automated processes enable continuous production with minimal downtime, while the repeatable accuracy of CNC machines reduces the need for rework. This streamlined approach allows manufacturers to meet tight deadlines without compromising quality, resulting in faster time-to-market and improved competitiveness. Ultimately, efficiency gained through CNC turning translates to higher-quality products at a lower cost per unit.

Enhancing Surface Finish and Product Aesthetics

The quality of a product is not solely determined by its functional performance; aesthetics and surface finish also play a vital role. Custom CNC turning excels in delivering superior surface finishes that meet both visual and functional requirements. Advanced CNC machines can perform high-precision turning, facing, and threading operations, resulting in smooth, uniform surfaces that enhance the overall appearance and usability of the component.

Furthermore, surface finish directly impacts product performance in certain applications. For instance, in the aerospace or automotive industries, smoother surfaces can reduce friction, improve mechanical efficiency, and extend the lifespan of components. By utilizing custom CNC turning, manufacturers can achieve a balance between functionality and aesthetics, ensuring that their products not only perform well but also meet the visual expectations of clients and end-users.

Flexibility in Design and Rapid Prototyping

Another key advantage of custom CNC turning is its flexibility in design. Unlike traditional machining, where design changes can be time-consuming and costly, CNC machines can be quickly reprogrammed to accommodate new specifications. This adaptability allows manufacturers to experiment with innovative designs, test prototypes, and respond to changing market demands without sacrificing product quality.

Rapid prototyping is a critical step in modern manufacturing, and custom CNC turning facilitates this process with precision and efficiency. Engineers can produce prototypes that closely replicate final production parts, enabling thorough testing and validation. By incorporating CNC turning into the prototyping stage, manufacturers can identify design flaws early, make necessary adjustments, and ultimately deliver a high-quality end product that aligns with client expectations.

Consistency Across Large Production Runs

Maintaining consistent quality across large production runs is a challenge in any manufacturing process. Custom CNC turning addresses this challenge effectively by combining automation with high-precision machining. Once a CNC program is established, every part produced follows the exact specifications, ensuring uniformity across hundreds or thousands of components. This consistency is critical for industries where interchangeability and reliability are essential, such as medical devices, electronics, and automotive components.

In addition, CNC machines offer detailed monitoring and quality control capabilities. Integrated sensors and inspection systems can detect deviations in real time, allowing for immediate corrective actions. By leveraging custom CNC turning technology, manufacturers can maintain high standards across large-scale production, reducing defects, minimizing waste, and reinforcing a reputation for delivering reliable, high-quality products.

Conclusion

In the modern manufacturing landscape, product quality is a non-negotiable requirement for competitiveness and customer satisfaction. Custom CNC turning has emerged as a transformative technology that empowers manufacturers to achieve precision, efficiency, and consistency at every stage of production. From precision engineering and superior surface finishes to rapid prototyping and large-scale consistency, CNC turning enhances product quality while optimizing operational processes.

By integrating custom CNC turning solutions into their production workflows, businesses can reduce material waste, improve efficiency, and deliver high-quality products that meet stringent industry standards. This technology not only enhances the functional and aesthetic aspects of manufactured components but also strengthens a company’s reputation for excellence. Ultimately, embracing custom CNC turning is a strategic investment that drives innovation, quality, and long-term success in manufacturing.