Choosing the Right Welding Table for Australian Fabrication

Learn how to choose the right welding table for Australian fabrication projects, focusing on quality, comfort, versatility, and long-term value.

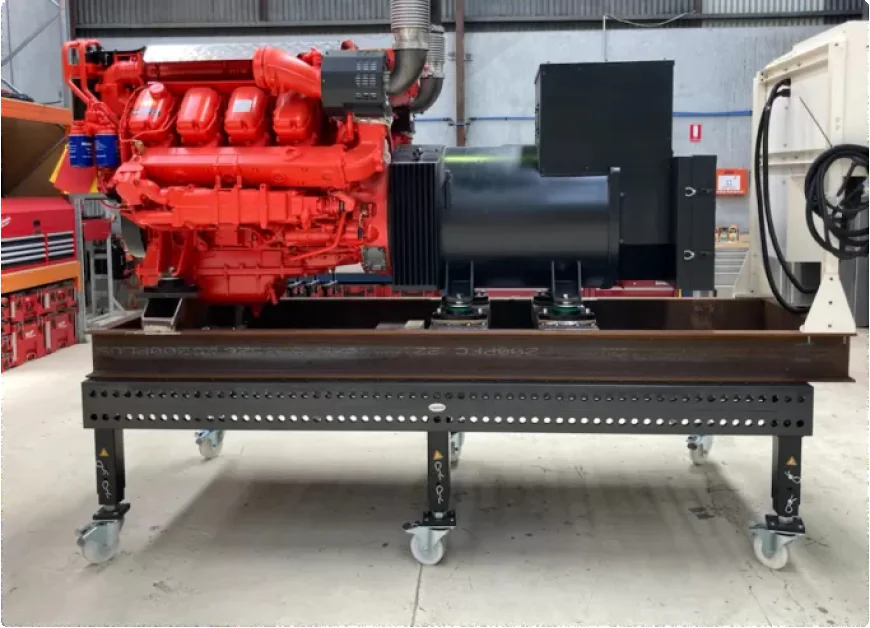

In fabrication, the table is more than just a surface. It is the foundation for accuracy, safety, and workflow. Whether you are fitting components, tacking frames, or finishing detailed work, the right table supports every step. For workshops comparing options across welding tables australia, the decision can feel overwhelming. Sizes, materials, load ratings, and layouts all matter, and choosing well can make daily work smoother and more enjoyable.

This guide breaks down what to look for and why it matters, based on real workshop needs and changing expectations across the industry.

Why the Right Welding Table Matters

A welding table affects how accurately you work and how comfortable you feel doing it. A flat, stable surface helps keep parts square and reduces rework. Poor tables can flex, warp, or shift under load, which leads to frustration and lost time.

We often see customers upgrading not because their skills have changed, but because their projects have grown more complex. A better table gives you confidence that the setup is right before you strike an arc.

Quality and Build You Can Rely On

Quality is usually the first thing people notice when they step up to a professional welding table. Thick steel tops, reinforced frames, and precision-machined surfaces all contribute to long-term performance.

Australian workshops often deal with heavy components and demanding environments. A table needs to handle heat, weight, and daily wear without losing flatness. Investing in solid construction means fewer compromises and less maintenance over time.

Comfort and Ease of Use in Daily Work

Comfort is not always the first thing people think about, but it plays a big role in productivity. Tables set at the right height reduce strain on your back and shoulders. Features like adjustable legs or compatible risers allow you to tailor the setup to your working style.

Ease of use also comes down to how quickly you can set up and change jobs. Hole patterns, clamping options, and clear access around the table all help keep work flowing without unnecessary pauses.

Versatility for Different Projects

Fabrication rarely stays the same. One week you might be building frames, the next repairing brackets or working on custom pieces. A versatile table adapts to different tasks without needing extra fixtures or awkward workarounds.

This is where modular designs shine. Being able to add extensions, clamps, or tooling means one table can support many types of work. For workshops comparing welding tables australia suppliers, versatility often becomes a deciding factor once the basics are covered.

Supporting a Better Customer Experience

From a business perspective, the right equipment directly affects customer outcomes. Accurate setups lead to better fit and finish. Reliable processes reduce delays and mistakes. Customers notice when work is consistent and delivered on time.

We see many workshops using their tables as a selling point. Clean layouts and professional equipment build trust when clients visit the shop floor. It shows that quality is taken seriously from the ground up.

Long-Term Value Over Short-Term Savings

It is tempting to choose a cheaper table and plan to upgrade later. In practice, this often costs more. Lower quality tables may need replacing sooner, or they slow down work enough that the savings disappear.

Long-term value comes from durability, adaptability, and support. A table that grows with your business and holds its accuracy over years offers far better returns than one that only meets minimum needs today.

Thoughtful Decisions and Sustainability

Sustainability is becoming part of equipment decisions, even in heavy industries. Buying well-made tables that last longer reduces waste and replacement cycles. Repairable components and modular systems also help extend product life.

Thoughtful purchasing is not just about environmental impact. It is about respecting your time, your team, and your investment. Choosing equipment that aligns with how you actually work leads to better outcomes all around.

Adapting to Changing Expectations

Fabrication customers expect more than ever. Tighter tolerances, faster turnaround, and consistent quality are now standard. Workshops respond by refining processes and upgrading tools that support precision and efficiency.

A modern welding table is part of that shift. It supports better planning, cleaner setups, and more repeatable results. As expectations rise, the tools you rely on need to keep pace.

Conclusion

Choosing the right table is a practical decision that influences how work gets done every day. From build quality and comfort through to versatility and long-term value, the right choice supports both skilled workmanship and steady business growth. For anyone comparing options across welding tables australia, focusing on what your workshop truly needs helps simplify the process. At Modern Tools, we believe a well-designed welding table should work just as hard as you do, delivering reliable results now and well into the future.