Acoustic Louvers vs Conventional Noise-Control Solutions: A Modern Approach to Smarter Noise Management

Among all available options, Acoustic Louvers have emerged as a highly effective modern solution. They are designed to manage noise while allowing free and continuous airflow.

Noise reduction has become a critical part of today’s industrial, commercial, and HVAC environments. As equipment becomes more powerful and workplaces demand quieter conditions, choosing the right noise-control system is no longer optional; it's essential for performance, safety, and regulatory compliance.

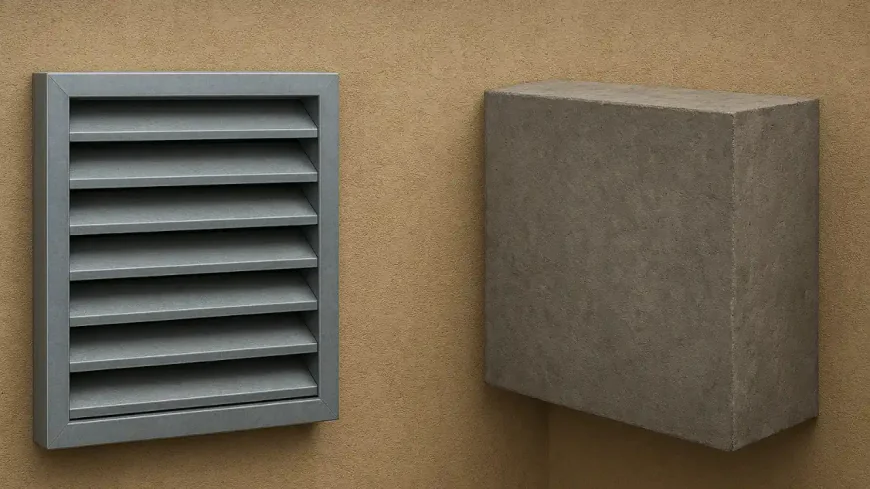

Among all available options, Acoustic Louvers have emerged as a highly effective modern solution. They are designed to manage noise while allowing free and continuous airflow. In comparison, traditional noise-control systems such as walls, enclosures, silencers, and acoustic panels have served the industry for decades but often involve structural limitations, airflow restrictions, and higher maintenance.

This refined comparison helps engineers, architects, facility managers, and industrial planners understand how acoustic louvers differ from conventional solutions and why they offer a more balanced approach in many real-world applications.

Understanding Acoustic Louvers and Their Purpose

An Acoustic Louver is a specially engineered ventilation component created to reduce noise without obstructing airflow. Unlike solid noise barriers, these louvers use multiple acoustically treated blades designed to absorb and block sound waves as air moves through them.

This makes them ideal for applications where equipment must stay ventilated such as generator rooms, HVAC systems, cooling towers, large industrial plants, commercial buildings, and mechanical enclosures.

High-quality louvers are typically built using galvanized steel, aluminum, or stainless steel. Inside each blade, sound-absorbing insulation helps capture mid- and high-frequency noise. Because they follow strict acoustic performance standards, these louvers deliver predictable, tested results even in harsh outdoor or industrial environments.

Where Traditional Noise-Control Methods Fit In

Before modern louvers became popular, industries relied heavily on concrete walls, solid enclosures, acoustic foam panels, duct silencers, mechanical insulation, and similar methods. These remain valuable in situations where airflow is not required or where extreme noise isolation is necessary.

However, these solutions also come with limitations such as heavy construction, space requirements, complex installation, and limited flexibility. Many traditional barriers restrict airflow, which can cause heat buildup in mechanical areas. This often leads to equipment strain, overheating, or added cooling requirements—raising both operational and maintenance costs in the long run.

Traditional methods are effective when used correctly, but they are not always suitable for environments where noise control and ventilation must work together.

How Acoustic Louvers Deliver Efficient Noise Reduction

The effectiveness of an Acoustic Louver comes from how it treats sound as air passes through it. Each blade inside the louver is designed to:

– absorb sound energy

– break the direct line of sound transmission

– reduce noise output before it reaches the external environment

– maintain airflow with minimal resistance

This dual-function design allows equipment to stay cool while still meeting noise-reduction targets. Louvers do not trap heat, restrict ventilation, or create backpressure the way enclosed systems sometimes do.

For higher acoustic performance, louvers can be designed with deeper blades, multi-bank configurations, or enhanced insulation depending on the project’s requirements.

Benefits That Make Acoustic Louvers Stand Out

Acoustic Louvers provide several advantages that traditional noise-control systems cannot match:

They support both airflow and noise reduction at the same time.

This makes them ideal for equipment that generates heat during operation.

They are lightweight and easier to install.

Most louvers require minimal structural support compared to concrete or masonry barriers.

Their design is flexible and architecturally appealing.

They can be used in building façades, industrial plants, and commercial spaces without affecting the aesthetic.

They offer long-term reliability and low maintenance.

Because they remain open and ventilated, louvers do not trap dust or moisture the way enclosed acoustic systems can.

They deliver faster return on investment.

By eliminating the need for separate cooling solutions and reducing maintenance costs, they often pay for themselves sooner than traditional barriers.

Why Traditional Noise-Control Systems Face Limitations

Conventional solutions still have their importance, but they often struggle with key challenges:

– heavier structural requirements and longer installation time

– reduced airflow, which can cause overheating

– high maintenance, especially in enclosed systems

– limited flexibility for future modification

– inconsistent acoustic performance if not installed perfectly

Many traditional barriers depend on mass and thickness to block sound, which means they require more space and stronger support structures. In contrast, acoustic louvers are engineered to provide predictable performance without extensive civil modifications.

ROI Perspective: Why Industries Are Shifting to Acoustic Louvers

Return on investment today extends beyond just installation cost. Facilities need solutions that:

– enhance equipment reliability

– reduce energy consumption

– require minimal maintenance

– offer measurable acoustic performance

– support safe system operation

Acoustic Louvers meet these expectations by addressing two major concerns—ventilation and noise—within a single system.

They help maintain ideal equipment temperatures, reduce operational stress, and avoid the need for complex cooling systems. Over time, this translates into lower maintenance bills, fewer component failures, and a more efficient overall facility.

Traditional systems, however, may require frequent repairs, insulation replacements, or reinforcement, which increases long-term costs and extends ROI timelines.

Future Trends That Strengthen the Case for Acoustic Louvers

The latest advancements in acoustic engineering have led to louvers that are stronger, lighter, and more efficient than ever. Modern designs now include:

– improved aerodynamic blade profiles

– high-performance acoustic cores

– corrosion-resistant materials for outdoor durability

– advanced rain and dust protection

– computer-simulated airflow and noise modeling

These improvements help louvers perform better even in extreme environments, making them a preferred choice for architects, engineers, and facility managers planning long-term infrastructure.

Acoustic Louver Solutions by SomNandi Industries

SomNandi Industries is recognized for delivering high-quality acoustic solutions, including premium Acoustic Louvers designed for industrial and architectural applications.

Their louvers combine advanced acoustic performance with efficient ventilation, ensuring reliable operation for HVAC installations, generator rooms, plant equipment, commercial buildings, and more.

With a strong engineering background and a solutions-oriented approach, SomNandi Industries customizes each louver system to match project requirements, environmental conditions, and industry standards.

Conclusion

The comparison between Acoustic Louvers and traditional noise-control systems clearly shows how modern needs have evolved. While older solutions remain effective in certain scenarios, they often struggle to provide the balance of airflow, acoustic performance, and long-term efficiency that today’s operations require.

Acoustic Louvers offer that balance. Their engineered design, low maintenance, and dual functionality make them an ideal solution for industries and buildings where cooling and sound control must coexist.

As noise standards rise and facility performance becomes a priority, acoustic louvers stand out as a reliable, future-ready, and cost-effective choice for modern noise management.