Industrial Metrology Market: Trends, Growth Drivers, and Future Outlook

The global Industrial Metrology market size was valued at USD 11.76 billion in 2024 and is projected to reach USD 19.19 billion by 2032, with a CAGR of 6.30 % during the forecast period of 2025 to 2032.

Introduction

The industrial metrology market is a critical component of modern manufacturing and quality assurance. Industrial metrology involves the measurement, inspection, and verification of dimensions, geometry, and physical properties of manufactured components. Accurate measurements ensure product quality, regulatory compliance, and operational efficiency across sectors such as automotive, aerospace, electronics, medical devices, and heavy machinery.

As industries increasingly adopt automation, precision manufacturing, and smart factory solutions, the industrial metrology market is witnessing robust growth. The integration of advanced measurement technologies, digital tools, and data analytics is transforming traditional quality control processes.

Source - https://www.databridgemarketresearch.com/reports/global-industrial-metrology-market

Market Overview

-

Market Size (2024): Approximately USD 10–11 billion

-

Forecast (2032): Expected to reach USD 18–19 billion

-

CAGR (2025–2032): Around 7–8%

Growth is fueled by rising demand for high-precision manufacturing, industrial automation, and stringent quality standards in key sectors.

Key Market Drivers

-

Rising Demand for Precision Manufacturing:

Automotive, aerospace, and electronics industries require extremely precise components, increasing demand for advanced metrology solutions. -

Technological Advancements:

Innovations such as coordinate measuring machines (CMMs), laser scanners, optical measurement systems, and portable 3D measurement tools enhance accuracy and reduce inspection time. -

Industry 4.0 and Smart Factories:

Integration of IoT, cloud computing, and AI-driven analytics into metrology systems allows real-time monitoring and predictive quality control. -

Regulatory Compliance and Standards:

Industries are increasingly adopting ISO, ASTM, and other international quality standards, driving the need for reliable measurement and inspection solutions. -

Rising Adoption in Emerging Economies:

Growth in industrial sectors in Asia-Pacific, Latin America, and the Middle East is increasing demand for metrology solutions to maintain quality and competitiveness.

Market Segmentation

By Product Type

-

Coordinate Measuring Machines (CMM): Widely used for high-precision dimensional measurements.

-

Laser Scanners and Optical Systems: Enable fast and non-contact inspection of complex geometries.

-

Profilometers and Surface Measurement Instruments: Used for texture and roughness analysis.

-

Gauges and Calipers: Manual and digital tools for basic measurement applications.

-

Software Solutions: Includes metrology software for data analysis, reporting, and process optimization.

By Application

-

Automotive: Ensures component accuracy and assembly quality in engines, chassis, and body panels.

-

Aerospace & Defense: Critical for aircraft components, turbine engines, and precision assemblies.

-

Electronics & Semiconductor: Used for wafer inspection, PCB measurement, and microelectronics manufacturing.

-

Medical Devices: Ensures compliance and precision in implants, surgical instruments, and diagnostic equipment.

-

Heavy Machinery & Industrial Equipment: Maintains tolerances in mechanical systems, gear assemblies, and hydraulic components.

By End User

-

Manufacturing Companies

-

Automotive & Aerospace OEMs

-

Medical Device Manufacturers

-

Electronics & Semiconductor Companies

-

Research & Development Institutes

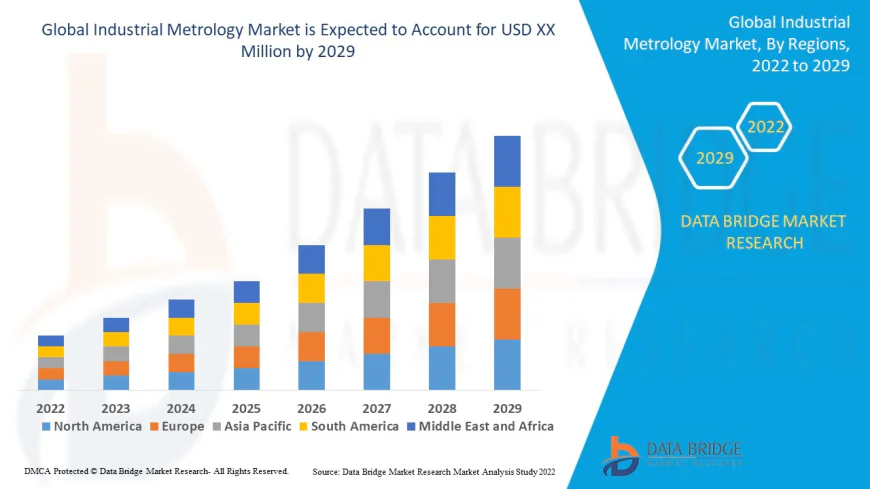

By Region

-

North America: Strong demand due to advanced manufacturing and adoption of digital metrology systems.

-

Europe: Growth driven by automotive, aerospace, and industrial automation sectors.

-

Asia-Pacific: Fastest-growing region due to industrial expansion in China, India, and Southeast Asia.

-

Latin America & Middle East: Emerging markets are gradually adopting metrology solutions for manufacturing quality improvement.

Key Market Trends

-

Non-Contact Measurement Technologies:

Adoption of laser, optical, and 3D scanning systems for faster, precise, and safer inspections. -

Integration with Artificial Intelligence:

AI and machine learning algorithms are used for predictive quality analytics and automated decision-making. -

Portable and Handheld Instruments:

Growth in demand for handheld 3D scanners and portable CMMs for on-site measurements. -

Cloud-Based Metrology Solutions:

Cloud storage and analytics enable real-time collaboration across manufacturing sites and locations. -

Sustainability and Resource Efficiency:

Metrology solutions are helping reduce material wastage, energy consumption, and production errors.

Challenges

-

High Initial Investment: Advanced metrology equipment requires significant capital expenditure.

-

Skilled Workforce Requirement: Trained personnel are essential to operate complex metrology systems and interpret results.

-

Integration Complexity: Aligning metrology solutions with existing production and digital systems can be challenging.

-

Rapid Technological Obsolescence: Continuous innovation requires frequent upgrades and system replacements.

Competitive Landscape

The industrial metrology market is highly competitive, with global and regional players offering a mix of equipment, software, and services. Leading companies include:

-

Hexagon AB

-

ZEISS Group

-

Mitutoyo Corporation

-

FARO Technologies, Inc.

-

Renishaw plc

These players focus on technological innovation, partnerships with industrial manufacturers, and expansion into emerging markets to maintain market leadership.

Future Outlook

The industrial metrology market is projected to maintain strong growth, driven by:

-

Increasing adoption of precision manufacturing and automated quality control.

-

Expansion of smart factories and Industry 4.0 initiatives.

-

Growth in emerging economies with industrial and technological modernization.

-

Integration of AI, IoT, and cloud-based analytics for enhanced measurement efficiency.

Future developments will likely focus on non-contact inspection, portable devices, and AI-powered predictive metrology solutions to improve operational efficiency and reduce production defects.

Conclusion

The industrial metrology market is experiencing robust growth due to rising demand for precision manufacturing, automation, and quality assurance. Advanced metrology solutions, combined with digital integration and AI analytics, are transforming the way manufacturers measure, monitor, and maintain product quality.

Companies that invest in technology innovation, skilled workforce training, and region-specific expansion are well-positioned to capitalize on the growing need for industrial metrology solutions across global manufacturing sectors.